Capillary tube double-path triggering device for series gap and application thereof

A technology of triggering devices and series gaps, which is applied in measuring devices, circuit breaker testing, instruments, etc., can solve the problems of increasing the technical difficulty of gas gap breakdown triggering, and meet the needs of precise timing control and good ablation resistance , The effect of improving the efficiency of the test work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

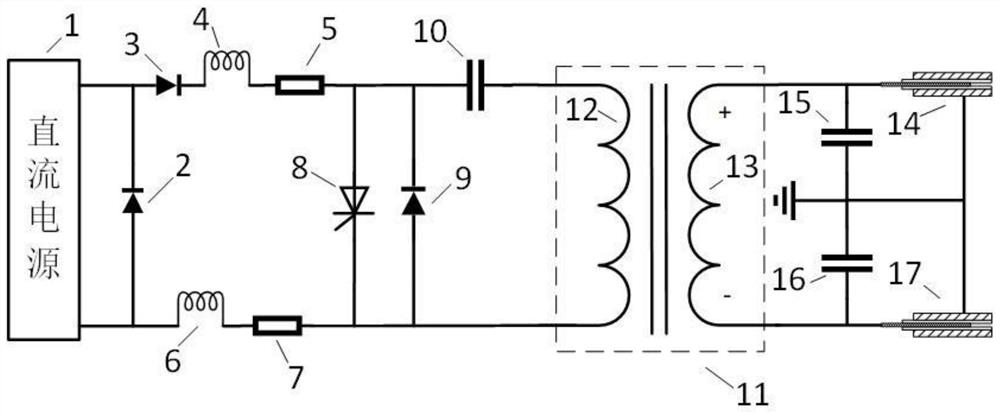

[0055] see figure 1 , the present embodiment is a capillary two-way trigger device for a series gap, including a pulse source, a single-gap capillary, and a voltage equalizing capacitor.

[0056] Pulse sources include pulse capacitors, DC power supplies, thyristors, freewheeling diodes, pulse transformers, protection inductors, protection resistors and protection diodes.

[0057] Wherein, the capacitance value of the pulse capacitor is 1 μF.

[0058] The DC power supply is connected in parallel to both ends of the pulse capacitor through a protection inductor and a protection resistor, and its output terminals are respectively connected in series and in parallel with protection diodes to form a pulse charging circuit together.

[0059] The pulse capacitor is connected in series with the parallel circuit of the thyristor and the freewheeling diode, and the primary side of the pulse transformer to form a pulse discharge circuit.

[0060] After receiving the pulse ignition sign...

Embodiment 2

[0067] see figure 1 , the present embodiment is a capillary two-way trigger device for a series gap, including a pulse source, a single-gap capillary, and a voltage equalizing capacitor.

[0068] Pulse sources include pulse capacitors, DC power supplies, thyristors, freewheeling diodes, pulse transformers, protection inductors, protection resistors and protection diodes.

[0069] Wherein, the capacitance value of the pulse capacitor is 2 μF.

[0070] The DC power supply is connected in parallel to both ends of the pulse capacitor through a protection inductor and a protection resistor, and its output terminals are respectively connected in series and in parallel with protection diodes to form a pulse charging circuit together.

[0071] The pulse capacitor is connected in series with the parallel circuit of the thyristor and the freewheeling diode, and the primary side of the pulse transformer to form a pulse discharge circuit. After receiving the pulse ignition signal, the thy...

Embodiment 3

[0078] see figure 1 , the present embodiment is a capillary two-way trigger device for a series gap, including a pulse source, a single-gap capillary, and a voltage equalizing capacitor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com