Building wall thermal resistance field test device and method

A technology for on-site testing and building walls, applied in the field of building wall thermal resistance testing, can solve the problems of unfavorable one-dimensional heat transfer, rapid establishment of heat transfer, large cooling/heating energy consumption, inconvenient installation and operation, etc., and save manpower for testing cost, improve the accuracy of results, and reduce the effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, and do not limit the protection scope of the present invention.

[0033] In order to better understand the present invention, an application example of a field testing device and method for building wall thermal resistance proposed by the present invention will be described in detail below.

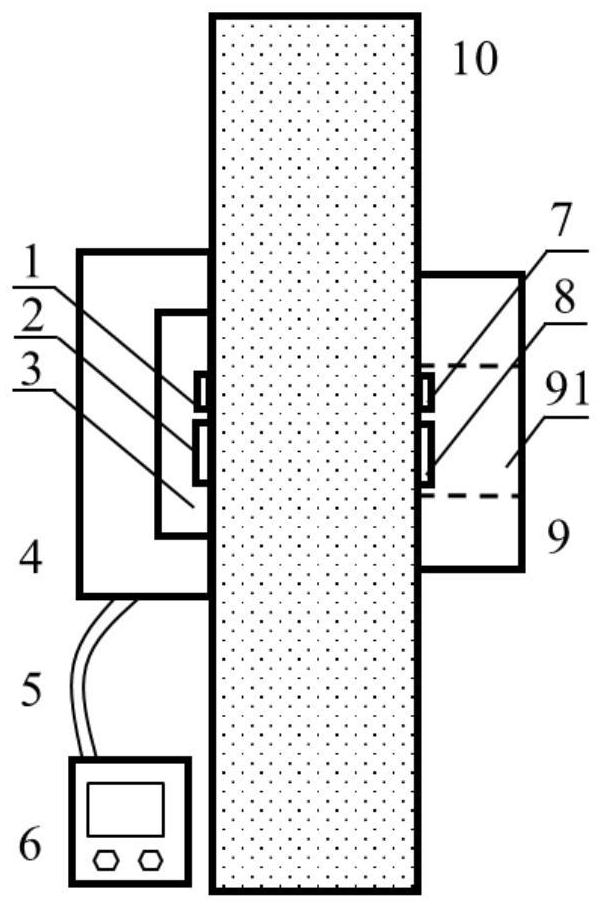

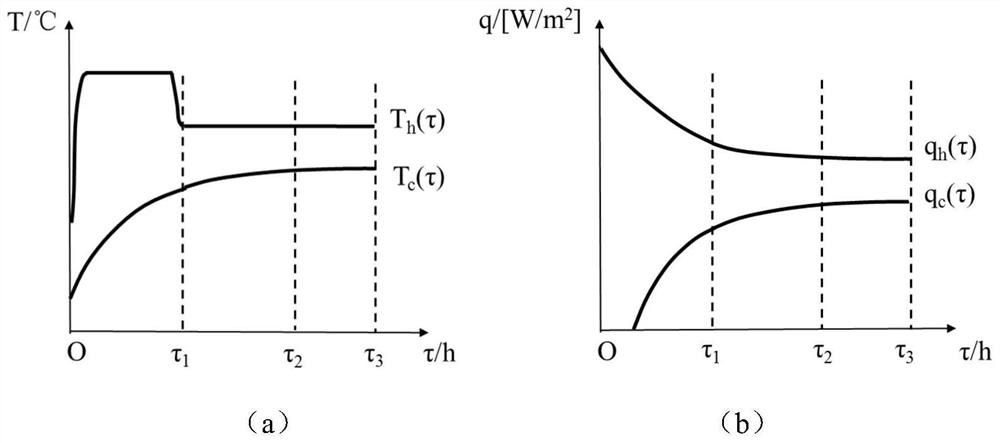

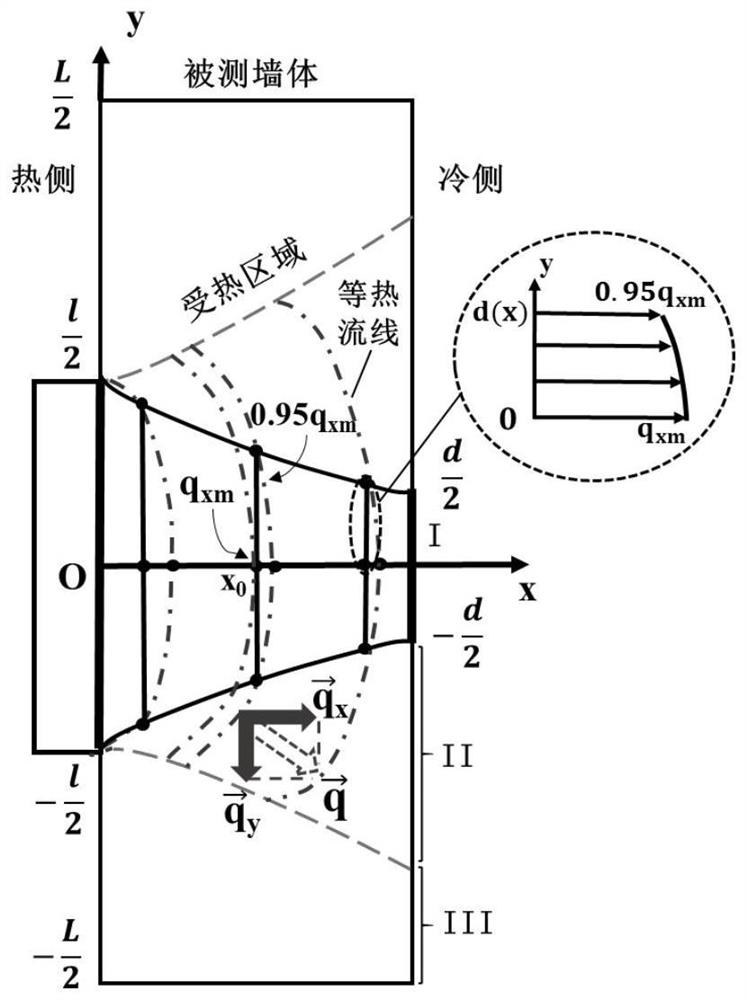

[0034] An on-site testing device for building wall thermal resistance in an embodiment of the present invention, its overall structure can be found in figure 1 , including heating plate 3, two temperature sensors (1 and 7), two heat flow sensors (2 and 8) and two heat preservation plates (4 and 9). Wherein, the first temperature sensor 1 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com