Anti-blocking water control screen pipe

A technology of water screen and water control valve, which is applied in the direction of production fluid, wellbore/well parts, earthwork drilling and production, etc. It can solve the problems of prolonging the production cycle of oil wells, affecting oil field production, reducing oil field water output, etc., and improving anti-clogging ability , To ensure the reliability of sand control and reduce the effect of erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

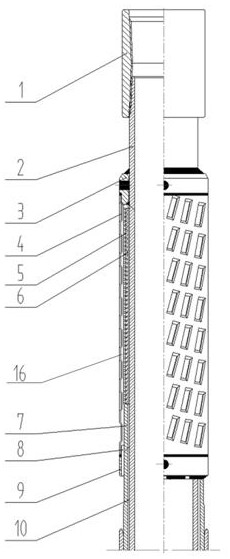

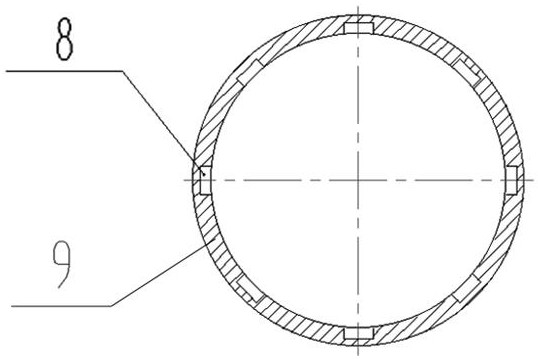

[0033] refer to Figure 1-3 As shown, an anti-blocking water control screen includes a base pipe 2, and the outer side of the base pipe 2 is sequentially covered with a wire-wrapped screen sleeve and a punching screen sleeve 4 from the inside to the outside, and the lower end of the wire-wrapped screen sleeve is connected with a support sleeve 7. A filtrate channel 10 is formed between the support sleeve 7 and the base pipe 2, and a sand passing channel 16 is formed between the wire-wound screen sleeve and the punching screen sleeve 4. The liquid is first filtered through the punching screen sleeve 4 and then passed through the wire-wrapped screen sleeve After the secondary filtration, it enters the base pipe 2, and the sand body passing through the slotting screen sleeve 4 is filtered by the wire-wound screen sleeve and then stays in the sand passage 16; the inner wall of the lower end ring 9 is provided with a plurality of falling sand grooves along the circumference 8. The ...

Embodiment 2

[0038] Others are the same as the first embodiment, except that the outer diameters of the upper end ring 3 and the lower end ring 9 are larger than the outer diameter of the punching screen casing 4 . This can effectively protect the screen from being squeezed and deformed during running downhole.

Embodiment 3

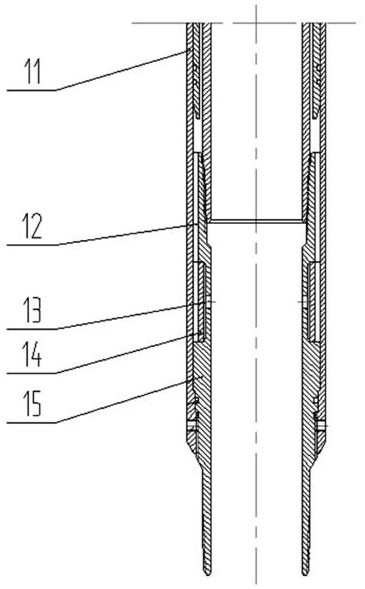

[0040] Such as Figure 4 As shown, the others are the same as the first embodiment, the difference is that the liquid inlet 17 of the water control valve 14 is provided with a plurality of baffles, and these baffles form a branch port with the liquid inlet 17, and the two ends of the branch port are respectively connected to the The liquid inlet 17 and the inner wall of the swirl cavity 18 form a streamlined track. In this way, when oil and water enter from the liquid inlet 17, no liquid flow resistance is formed, which can effectively reduce the frictional resistance of the oil and lengthen the flow of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com