Sliding-plug escape door

An escape door and Sierra technology, applied in the field of Sierra escape doors, can solve the problems of poor sealing of the car door, no good solution, damaged acceleration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

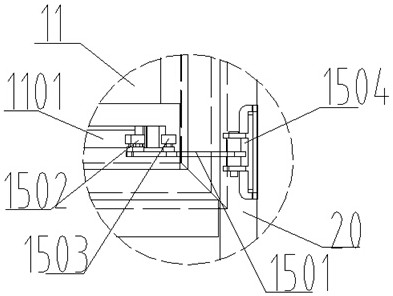

[0070] This embodiment provides a double Sierra escape door, such as Figures 1 to 11 , 19 to 25, mainly by the base 1 fixed on the door frame 20, two groups of shaft-connected drive mechanisms 2, slide rod 3, pull rod 4, two sliding sleeves 5, wire drawing 6, two wire drawing wheels 7, Guide wheel 8, gas spring 21, two door frames 10, two door panels 11, four safety locks 25 and a manual unlocking pull bar 24 form.

[0071] Two sets of shaft-connecting drive mechanisms 2 are respectively installed on both ends of the upper part of the base 1. The two sets of shaft-connecting drive mechanisms 2 are mainly composed of a sliding bracket 201, a driving arm 202 and a connecting arm 203. The sliding brackets in the two sets of coupling driving mechanisms 2 201 is fixedly connected through the slide bar 3, and the driving arm 202 is rotatably connected through the pull rod 4, and the slide bar 3 and the pull rod 4 are parallel to each other. Among the two groups of shaft-connecting...

Embodiment approach 2

[0078] This embodiment is a further improvement of Embodiment 1. The main improvement is that in Embodiment 1, when the emergency situation is over and it is necessary to close the opened double-serra safety door, it is necessary to manually turn the escape doors on both sides to After pushing hard in the middle to close, re-lock the four safety locks 25 on both sides; since the escape door is in the emergency opening state of the gas spring 21, the gas spring 21 is always in an extended state. Pushing the escape door to the middle to close the escape door is very time-consuming and laborious, and the operation is difficult. However, in this embodiment, the above-mentioned defects can be effectively overcome.

[0079] Specifically, the double plug safety door in this embodiment also includes a driving cylinder, which is fixed on the pull rod, and its telescoping end is fixedly connected with the sliding sleeve 5 connected with the guide wheel 8 . After the Sierra escape door ...

Embodiment approach 3

[0086] This embodiment is a further improvement of Embodiment 2. The main improvement is that in Embodiment 2, when the emergency is over, it is necessary to manually pull the manual unlocking lever first, and pull the unlocking piece of the safety lock 25 through the unlocking wire 23 to release it. After the safety lock 25 is unlocked, the gas spring 21 can be stretched quickly to open the door panel. The pulling of the manual unlocking lever requires manpower. In this embodiment, a pneumatic unlocking cylinder 22 is installed on the inner wall of the double-serra escape door, and the telescopic end of the pneumatic unlocking cylinder 22 is connected to the unlocking pieces of each safety lock 25 through unlocking wires 23 .

[0087] The setting of the pneumatic unlocking cylinder 22 enables the opening of the safety lock 25 to be opened pneumatically. The operation is only to touch the opening button of the pneumatic unlocking cylinder 22. After the pneumatic unlocking cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com