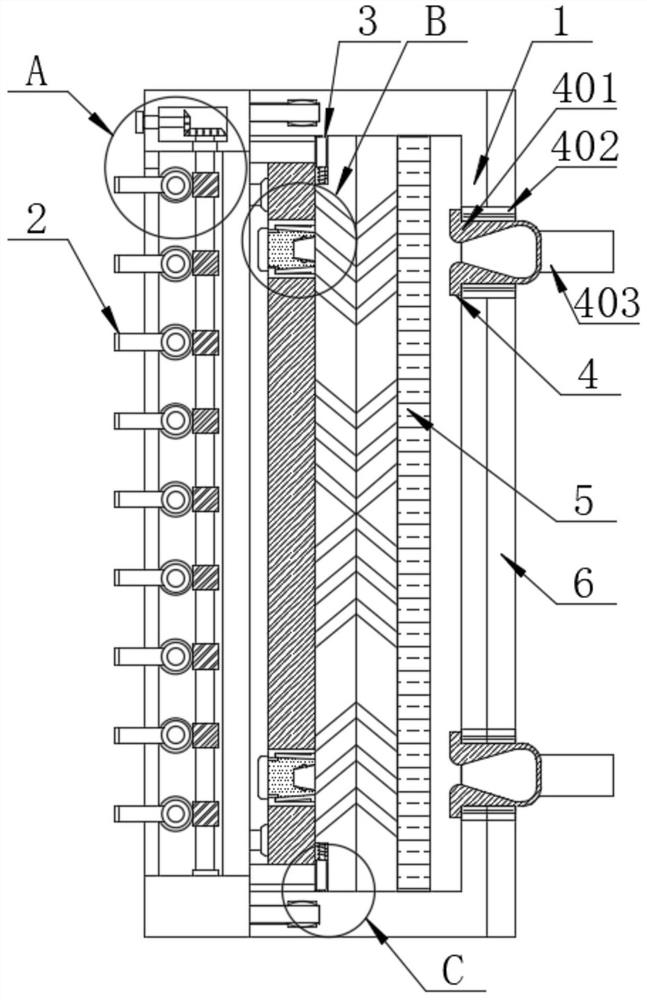

Building main body structure with built-in heat preservation gypsum board

A technology for building main body and gypsum board, which is applied to building components, building structures, buildings, etc., can solve the problems of insufficient ductility, long construction period, and easy drying of gypsum thermal insulation boards, so as to improve the usable range and assembly. The effect of adaptability and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

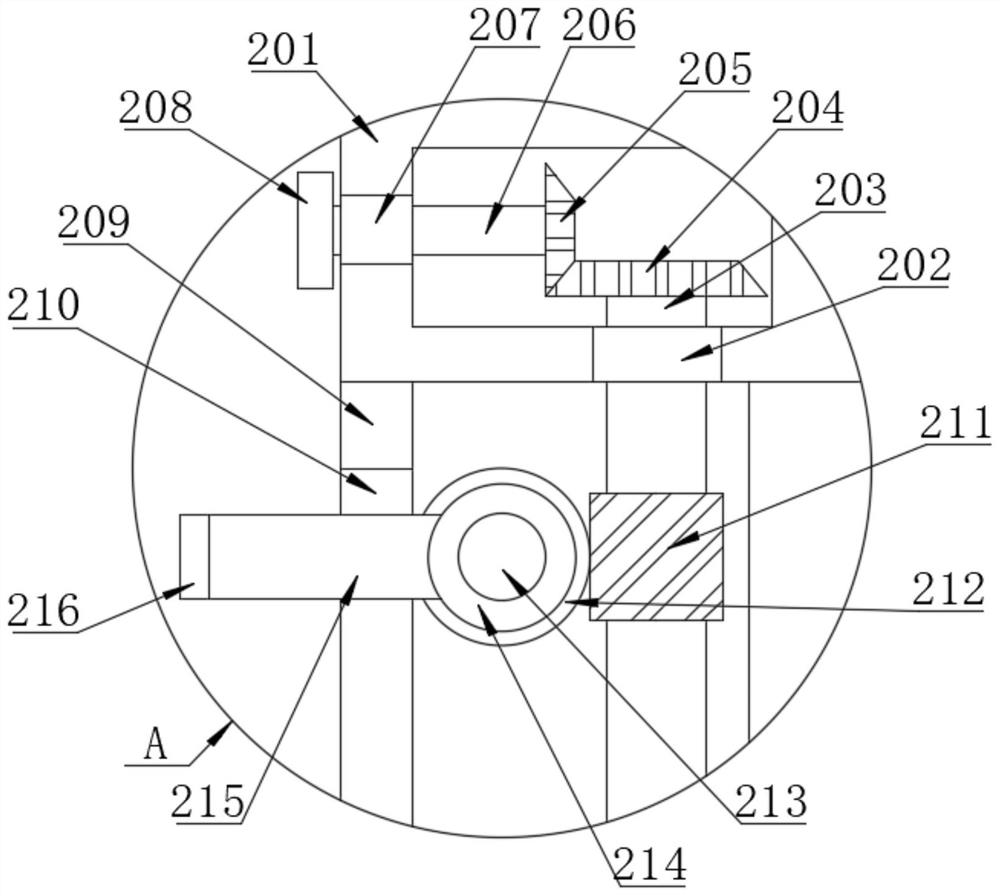

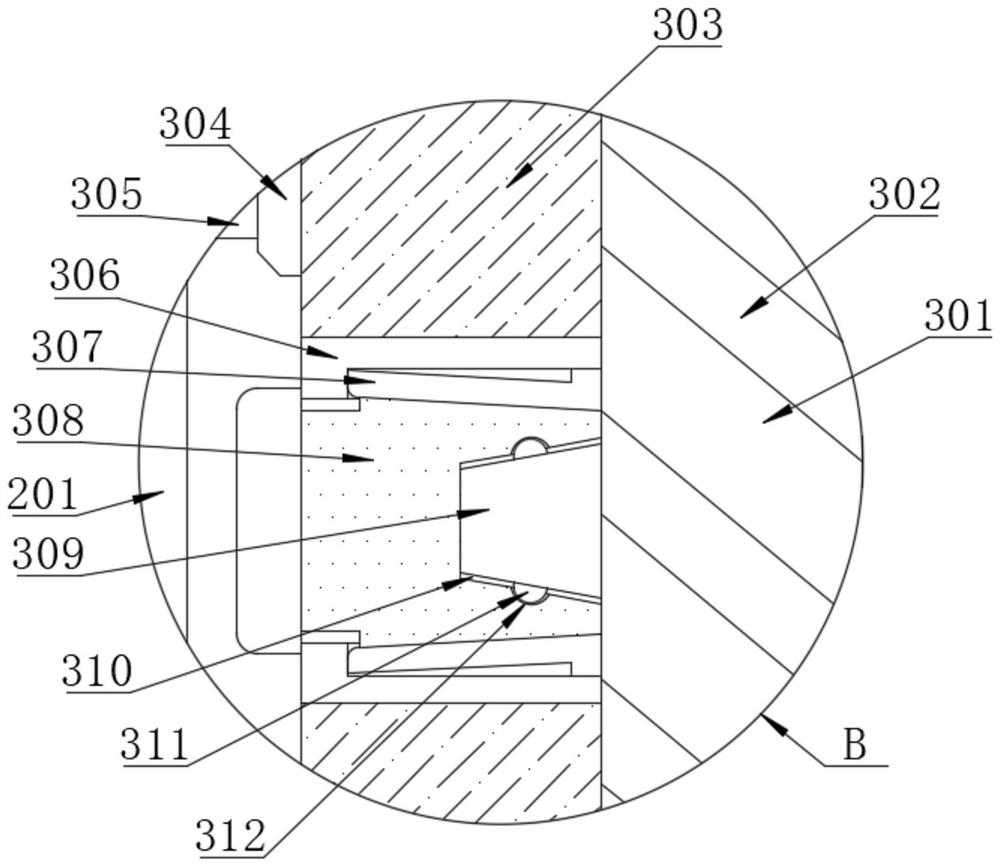

[0038] The specific embodiment is as follows: after the plaster mechanism 3 in the fixed shell 1 is assembled, the second rotating shaft 206 can be driven to rotate in the second bearing 207 by twisting the handle 208, and the rotation of the second rotating shaft 206 drives the driving gear 205 to rotate, and the driving gear 205 The rotation drives the driven gear 204 to rotate, the driven gear 204 rotates to drive the first rotating shaft 203 at the bottom to rotate, the first rotating shaft 203 rotates more stably in the first bearing 202, and avoids the bottom worm 211 from shifting, and the first rotating shaft 203 rotates to drive The bottom worm 211 rotates, the worm 211 rotates to drive the threaded worm wheel 212 to rotate, the worm wheel 212 rotates to drive the shaft sleeve 214 to rotate in the third bearing through the third shaft 213, and the shaft sleeve 214 rotates to drive the side baffle 215 to rotate and move downward. At this time, the opened baffle 215 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com