Center coke adding and distributing method

A cloth and sub-center technology, applied in the field of metallurgy, can solve the problems of reduced fuel consumption, large amount of coking in the center, low gas utilization rate, etc., and achieve the effects of reduced fuel consumption, enhanced liquid permeability, and accelerated renewal speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

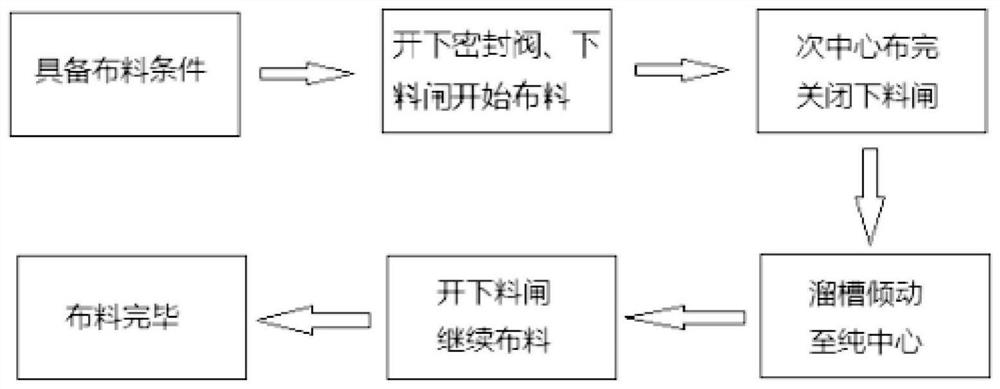

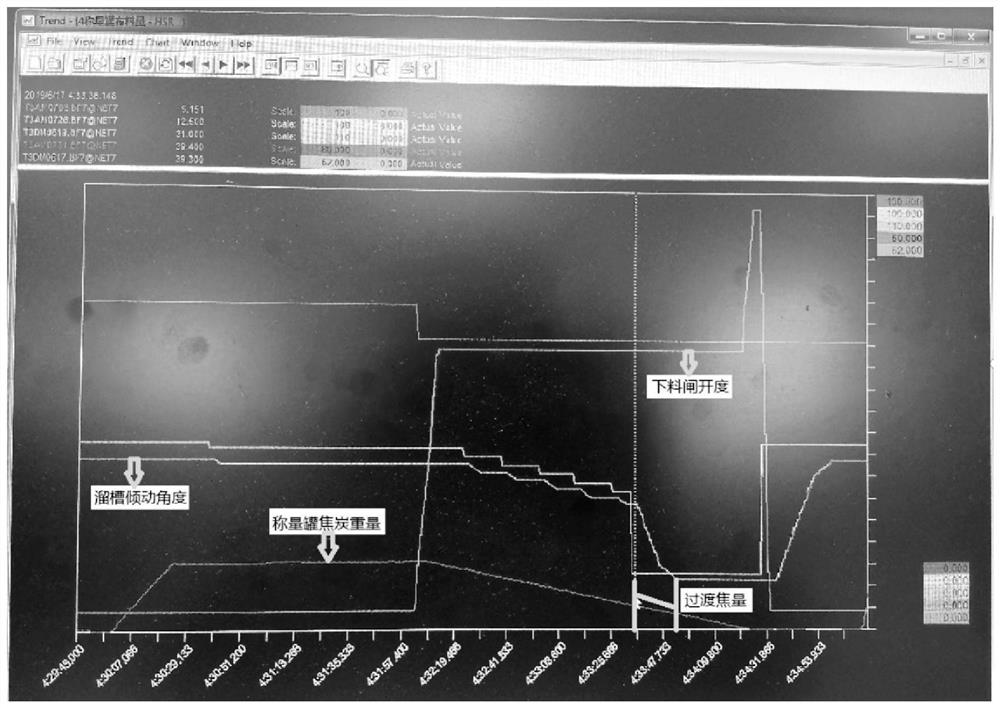

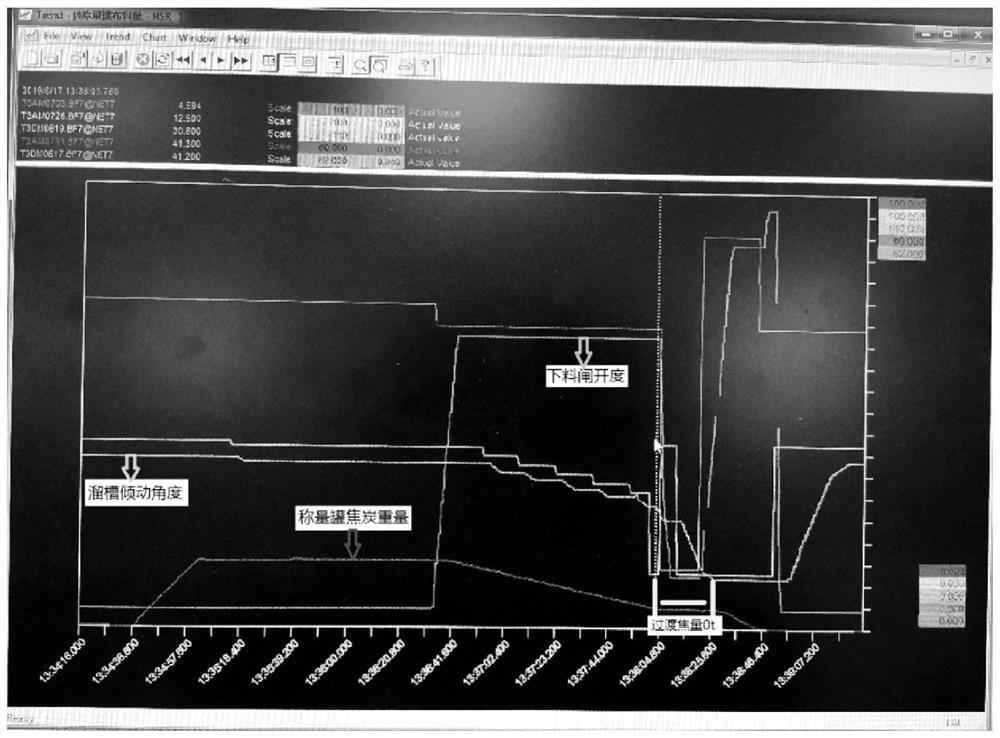

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings. As shown in the figure, when the material distribution conditions are met, open the lower sealing valve and the material discharge gate to start material distribution, set according to the material distribution matrix, and close the material discharge gate after the sub-center coke is distributed. The chute is no longer feeding into the furnace, and the chute continues to tilt. After the chute reaches the pure center to set the feeding angle, the feeding gate is opened to the maximum to continue feeding until all the coke in the weighing tank is distributed into the furnace, and the feeding ends.

[0015] The method of the invention enhances the controllability in the process of distributing cloth. In the early stage, the method of coke distribution is the same as that of the original center. When there is no coke in the mining area at the beginning, when the angle is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com