Container type oxygen generation system

An oxygen production system and container-type technology, applied in the field of oxygen production, can solve the problems of large occupied space, inflexible application, inability to move, etc., and achieve the effects of extending service life, reducing noise pollution and facilitating maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

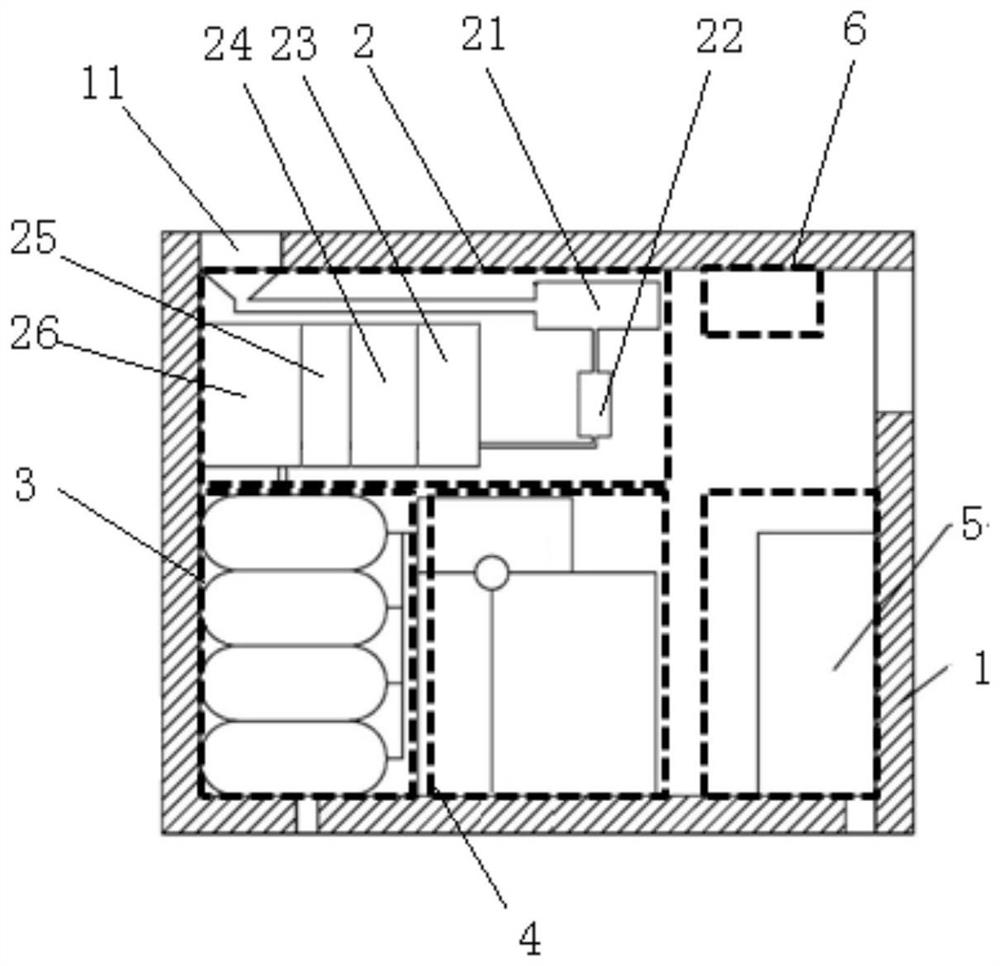

[0025] Refer to attached figure 1 As shown, the container-type oxygen production system of this embodiment includes a container body 1 and an air treatment module 2 , an air storage tank module 3 , an oxygen production device module 4 and a control mechanism module 5 disposed therein.

[0026] The air treatment module 2 includes an air compressor 21 , a high-efficiency degreaser 22 , a precision filter 23 , a freeze dryer 24 , a fine dust filter 25 and an activated carbon filter 26 connected in sequence. Wherein the air inlet pipe of the air compressor 21 communicates with the air inlet 11 on the container body 1 .

[0027] The air inlet of the gas storage tank module 3 is connected to the air outlet pipe of the activated carbon filter 26 , and its air outlet is connected to the air inlet pipe of the oxygen generator module 4 .

[0028] The air outlet pipe of the oxygen generator module 4 is connected with the oxygen output pipe 12 passing through the container body 1 for pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com