Zero power hovering system and method for small underwater equipment

A small water and hovering technology, which is applied to underwater operation equipment, underwater ships, motor vehicles, etc., can solve the problems of large power consumption and weak battery life of underwater robot equipment, and achieve easy speed control, reduce design and Effects that are difficult to manufacture and simple in structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

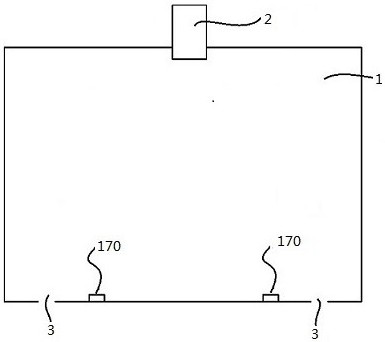

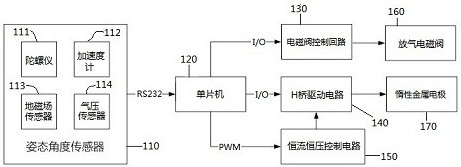

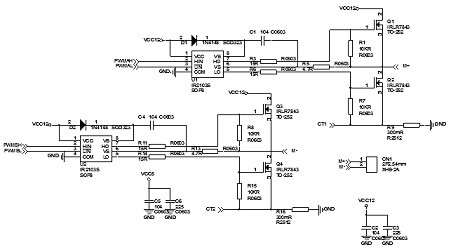

[0029] In this example, if figure 1 and as figure 2 As shown, a zero-power hovering system suitable for small unmanned underwater equipment includes a watertight cabin 1, a water electrolysis module installed inside the watertight cabin 1 for generating gas, and a lift controller to control the movement of the watertight cabin 1 . The top of the watertight chamber 1 is provided with an air vent 2 , and the bottom of the watertight chamber 1 is provided with a water outlet 3 . The lift controller includes a lift control circuit board module and a lift control execution module, and the modules are electrically connected. The lifting control circuit board module includes an attitude angle sensor 110, a single-chip microcomputer 120, and a solenoid valve control circuit 130. The lifting control execution module inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com