Paper pallet production line

A production line and paper pallet technology, applied in the field of automated production lines, can solve problems such as singleness and low processing efficiency, and achieve the effects of improving bonding stability, increasing production efficiency, and improving automated production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

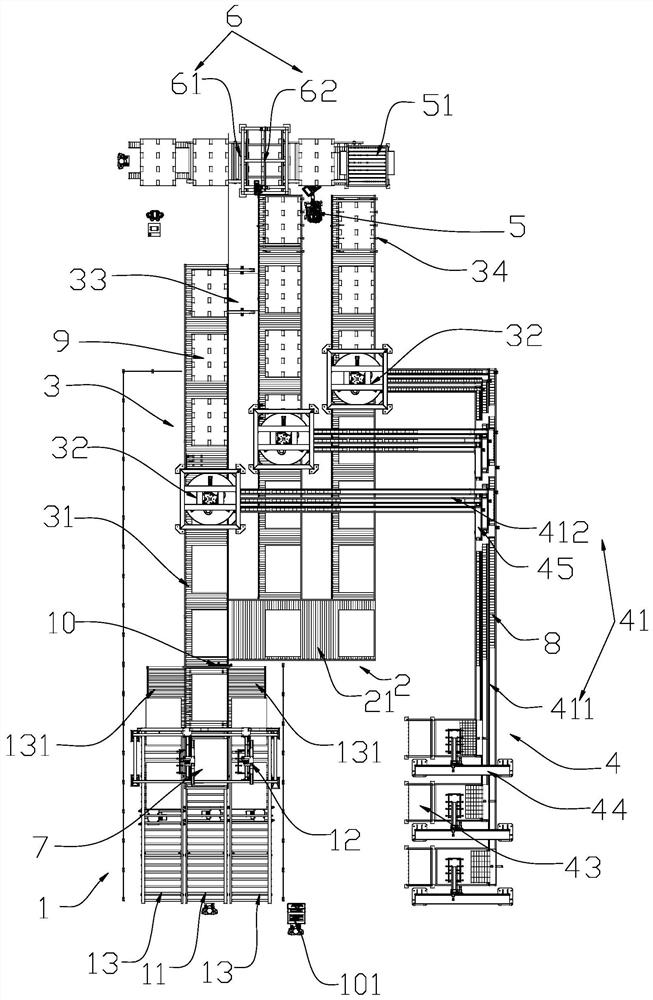

[0038] Wherein, the feeding device 1 is provided with a feeding drum 11 , and the feeding drum 11 transports the cardboard 7 to the feeding device 2 .

[0039] Specifically, feeding rollers 13 are provided on both sides of the feeding roller 11 , and feeding clamps for clamping the cardboard 7 on the feeding roller 13 to the feeding roller 11 are arranged on the feeding roller 11 .

[0040] Further, the feeding drum 13 is provided with a cardboard recovery area 131. When it is necessary to replace the cardboard 7 with different specifications, the feeding drum 13 transports the cardboard 7 to the cardboard recycling area 131, and the cardboard 7 is taken out by a forklift or a robot. Put in the cardboard 7 of different specifications again.

[0041] Specifically, the distributing device 2 is provided with a distributing drum 21 , and the distributing drum 21 is connected with the feeding drum 11 to transport the cardboard 7 to the bonding device 3 .

[0042] Further, the dist...

specific Embodiment 2

[0072] An encoding device 10 is provided at the junction of the distribution device 2 and the feeding device 1 of the paper pallet production line in this embodiment.

[0073] Specifically, the coding device 10 is used for spraying codes on the cardboard 7 , and different specifications of the cardboard 7 are sprayed with different codes.

[0074] Wherein, there are a plurality of distributing mechanisms on the distributing drum 21 of the distributing device 2, the distributing mechanisms are set corresponding to the bonding drum 31, and the distributing mechanism is provided with a detection device for detecting the code of the cardboard 7. equipment.

[0075] Specifically, when the cardboard 7 enters the distribution cylinder 21 , the distribution mechanism distributes the cardboard 7 of different specifications to different bonding cylinders 31 according to the code detected by the detection device.

[0076] The automatic production steps of the paper pallet production lin...

specific Embodiment 3

[0086] The foot pier conveying device 4 of the paper pallet production line in this embodiment has at least two foot pier conveyor belts 41 .

[0087] Wherein, the specifications of the foot pier 8 on each foot pier feeding mechanism 43 can be the same or different.

[0088] Specifically, when the specifications of the cardboard 7 in a plurality of bonding areas 32 are the same, the same pier 8 can be provided by the pier feeding mechanism 43 to produce pallets 9 of the same specification, or the pier 8 of different specifications can be used to produce pallets 9 of the same specification. , to produce pallets 9 of different specifications.

[0089] Specifically, when the specifications of the cardboards 7 in the bonding areas 32 are different, the pier 8 of the same or different specifications can be provided by the pier feeding mechanism 43 to produce pallets 9 of different specifications.

[0090] Wherein, the pier feeding mechanism 44 is a multi-axis robot.

[0091] Spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com