Convenient-to-open injection mold for gear part

A technology for injection molds and gear parts, which is applied to household appliances, other household appliances, applications, etc., and can solve the problems of occupation, inconvenience for mold opening and use, and large overall volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

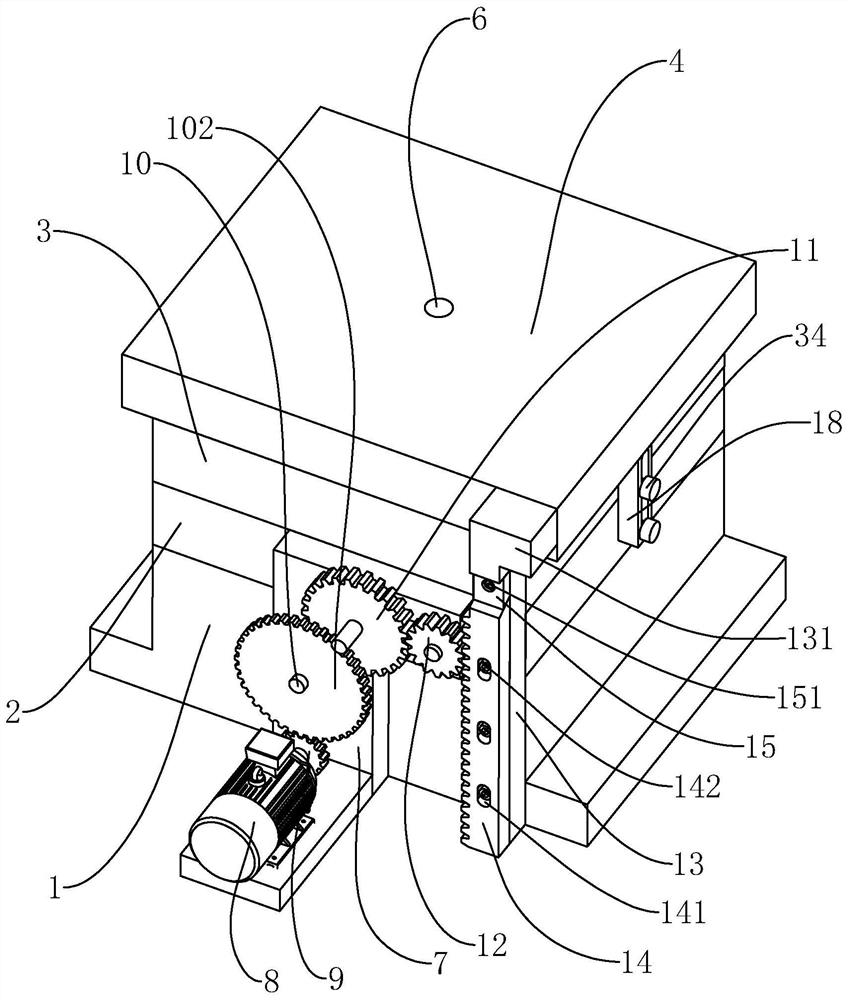

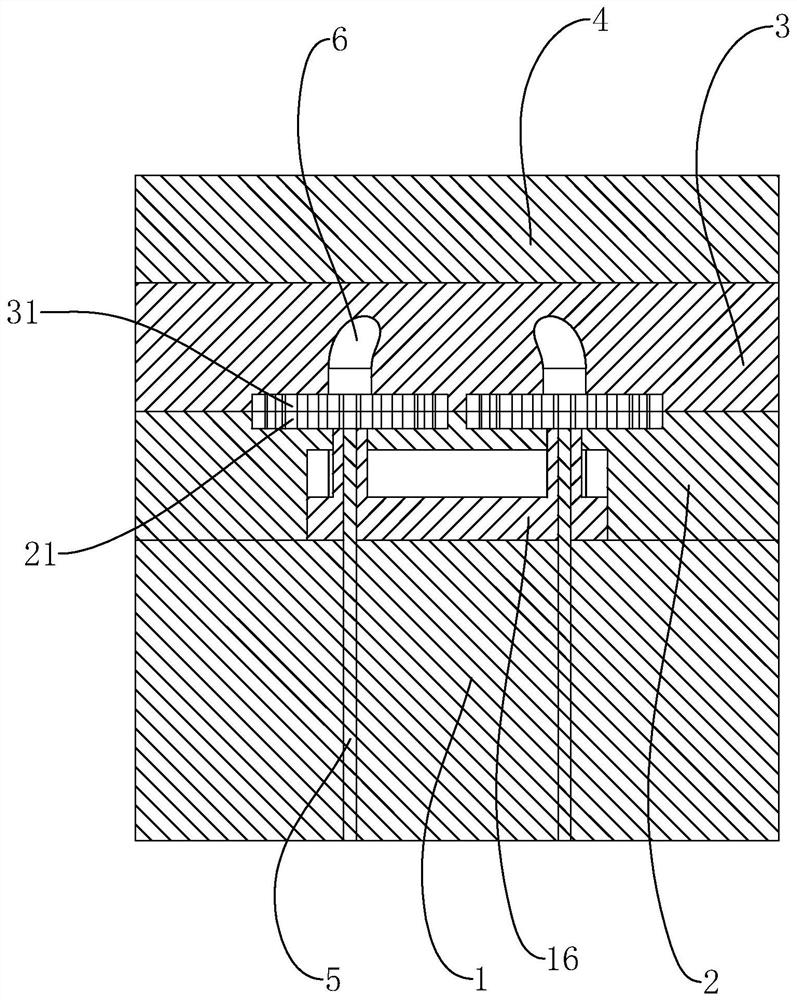

[0042] refer to figure 1 with figure 2 , an injection mold for gear parts that is convenient for mold opening, comprising a rear mold base 1, the rear mold base 1 is in a square shape. Rear mold core 2, front mold core 3 and front mold base 4 are arranged successively on the rear mold base 1, and the rear mold core 2, front mold core 3 and front mold base 4 are all in a square shape and correspond to the rear mold base 1. One end of the rear mold core 2 facing the front mold core 3 is provided with four rear mold cavities 21 , and the four rear mold cavities 21 are evenly distributed on the rear mold core 2 . A thimble 5 is slidably connected in the rear mold base 1 , and the end of the thimble 5 communicates with the cavity 21 of the rear mold. An end of the front mold core 3 close to the rear mold core 2 is provided with a front mold cavity 31 facing the rear mold cavity 21, and the front mold cavity 31 cooperates with the rear mold cavity 21 to form a gear shape that nee...

Embodiment 2

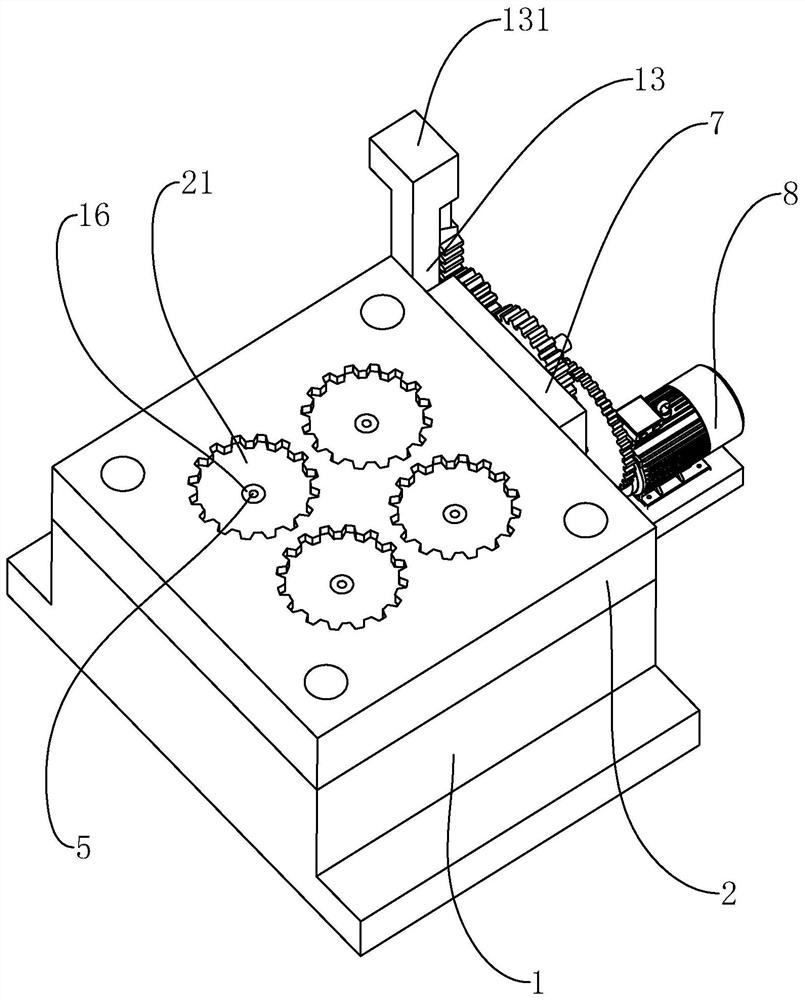

[0055] refer to Figure 5 with Figure 7 The difference between the second embodiment and the first embodiment is that the ejection mechanism 17 is different. The ejection mechanism 17 includes an ejection screw 173, and the ejection screw 173 is placed in the rear mold base 1 and is rotatably connected with the rear mold base 1. The end of the ejector screw 173 is placed in the ejector plate 16 and is threadedly connected with the ejector plate 16 , and the ejector screw 173 and the ejector plate 16 are perpendicular to each other. The other end of the ejecting screw 173 is fixedly provided with a worm gear 174 , and the end of the connecting shaft 10 is fixedly provided with a worm screw 175 engaged with the worm gear 174 , and the worm screw 175 is coaxial with the connecting shaft 10 . The connecting shaft 10 rotates, and then drives the worm 175 to rotate. Through the meshing connection between the worm 175 and the worm wheel 174, the rotation of the ejector screw 173 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com