A mold clamping mechanism of an injection molding machine driven by a diamond-shaped connecting rod and a double-wire screw

A technology of injection molding machine and thread, which is applied in the field of mold clamping mechanism of injection molding machine, can solve the problems of low template parallelism, unbalanced template force, large template deformation, etc., to improve the quality of injection molding products, short movement cycle, The effect of small deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

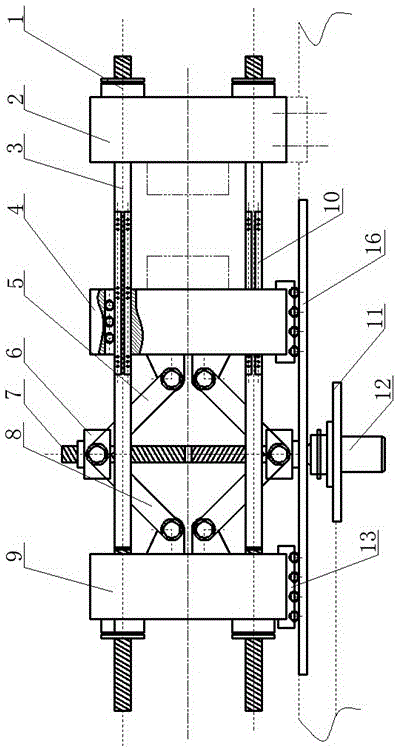

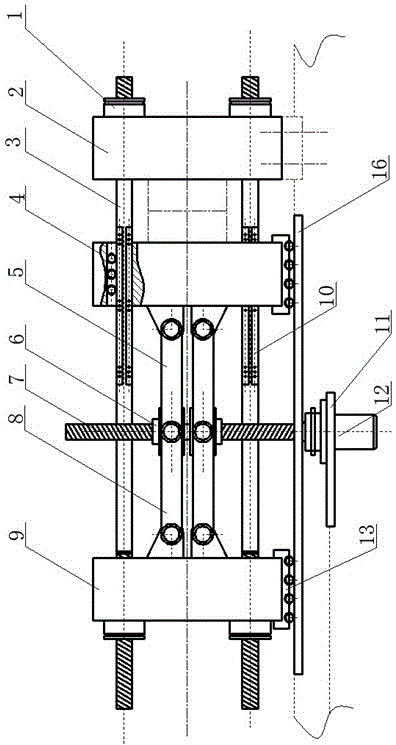

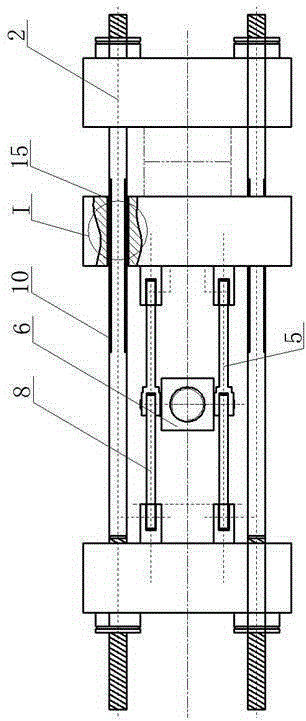

[0016] Such as figure 1 , figure 2 , image 3 As shown, the present invention includes a front template 2, a movable template 4, a rear template 9, four pull rods 3, two left connecting rods 8, two right connecting rods 5, two nuts 6, a double wire lead screw 7, and a servo motor 12. Two sets of roller sets 13, the first guide rail set 10, the short guide rail 11, the second guide rail set 15 and the long guide rail 16; there are tie rod holes on the four corners of the rear template 9, the movable template 4 and the front template 2, and four pull rods 3 After passing through the tie rod holes of the rear formwork 9, the moving formwork 4 and the front formwork 2 in turn, one end of the four tie rods 3 is fixedly connected to the front formwork 2, and the other ends of the four tie rods 3 are fixedly connected to the back formwork 9, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com