Particle material centralized feeding system

A feeding system and granular material technology, which is applied in the field of granular material centralized feeding system, can solve the problems of material ratios that do not meet the requirements of multiple devices and material residues, so as to improve the effect of rotation, ensure accuracy, and improve supply. The effect of material efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

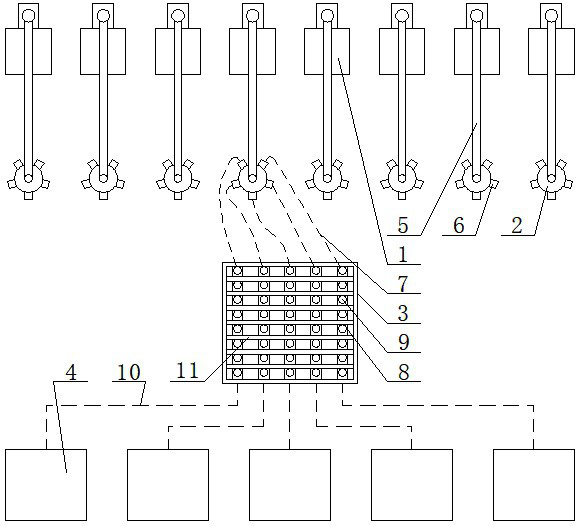

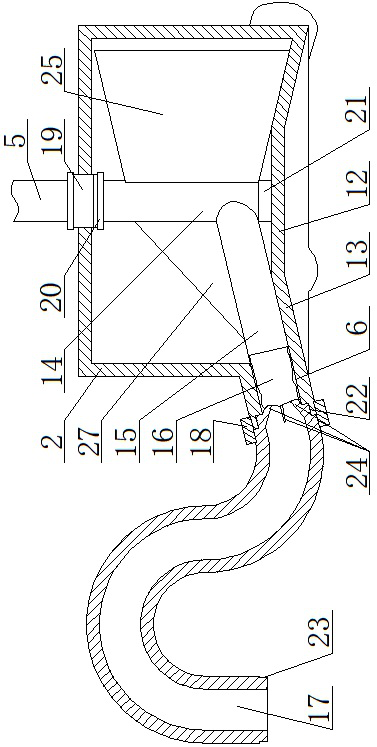

[0032] combine Figure 1~Figure 2 It can be seen that the granular material centralized feeding system of the present invention includes a plurality of material tanks 1 and a plurality of injection molding machines 4, and the material tanks 1 are communicated with the injection molding machines 4 through the material centralized receiving device 3, and the material concentrated receiving device 3 is connected to the injection molding machine 4. 3 is provided with a plurality of centralized material collection pipes 8, the top of each centralized material collection pipe 8 is provided with a plurality of material collection ports 9 along the axial direction of the centralized material collection pipe 8, and the number of the centralized material collection pipes 8 is greater than Equal to the quantity of injection molding machines 4, the quantity of the material receiving port 9 of each concentrated material collecting pipe 8 is greater than or equal to the quantity of the mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com