A method for off-line programming of a multi-axis robot

A multi-axis robot and programming technology, which is applied in the direction of program control manipulators, manipulators, manufacturing tools, etc., can solve the problems of large operation errors and errors, achieve the effect of small relative errors, reduce difficulty, and enhance reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

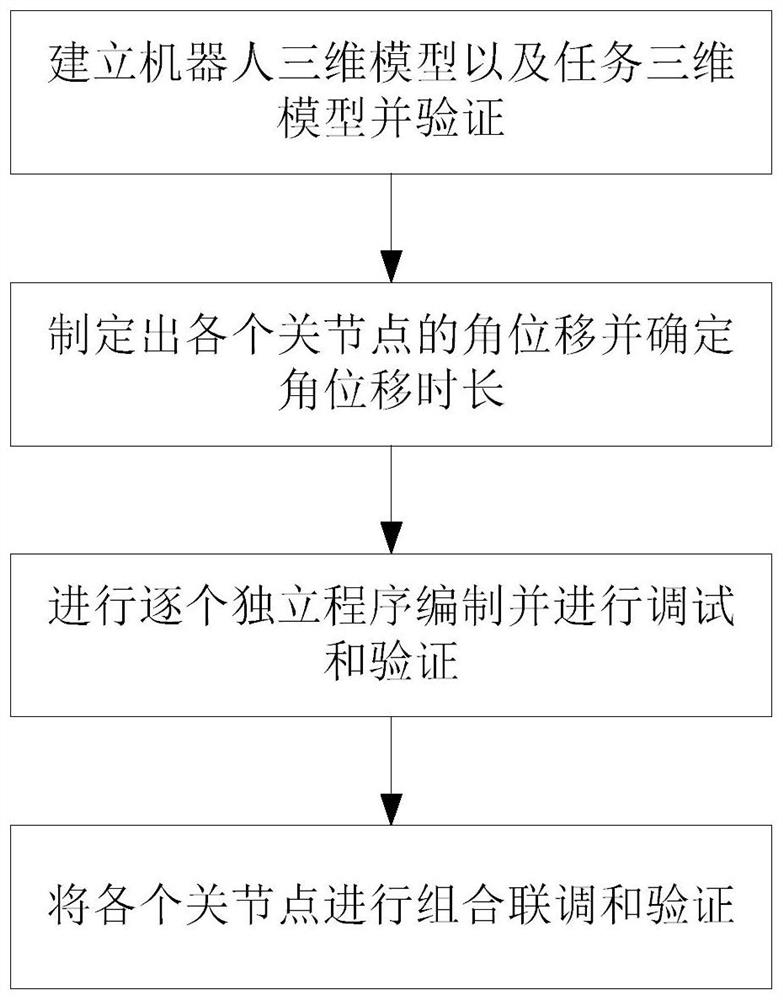

[0037] Such as figure 1 As shown, the multi-axis robot offline programming method disclosed in the present invention includes the following steps:

[0038] Step 1, establish the robot 3D model of the multi-axis robot and the task 3D model of the task, which can be obtained by scanning the multi-axis robot and the task through the existing 3D scanning technology, and approximate the model of the robot 3D model and the task 3D model The real-time point cloud data of 3D scanning is converted into the point cloud data format supported by AutoCAD through Autodesk ReCap software, and then the 3D modeling is completed through the plug-in PointShape modeling tool of AutoCAD;

[0039] Step 2, after the model approximation verification is passed, the angular displacement of each joint point in the robot's 3D model is formulated according to the task 3D model, and the angular displacement duration of each joint point is determined; when formulating the angular displacement and angular di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com