A system and method for continuous production of glyphosate ammonium salt granules

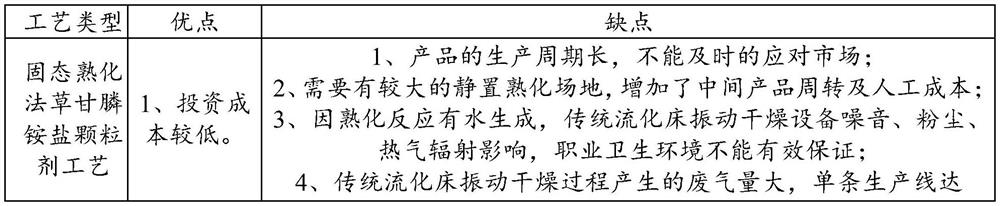

A technology of glyphosate ammonium salt and granules, which is applied in the system field of continuous production of glyphosate ammonium salt granules, which can solve the problems of high environmental protection wastewater treatment costs, high tail gas treatment operation costs, and unsatisfactory occupational health and environment. , achieve high production efficiency, good product quality, and solve the effect of high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

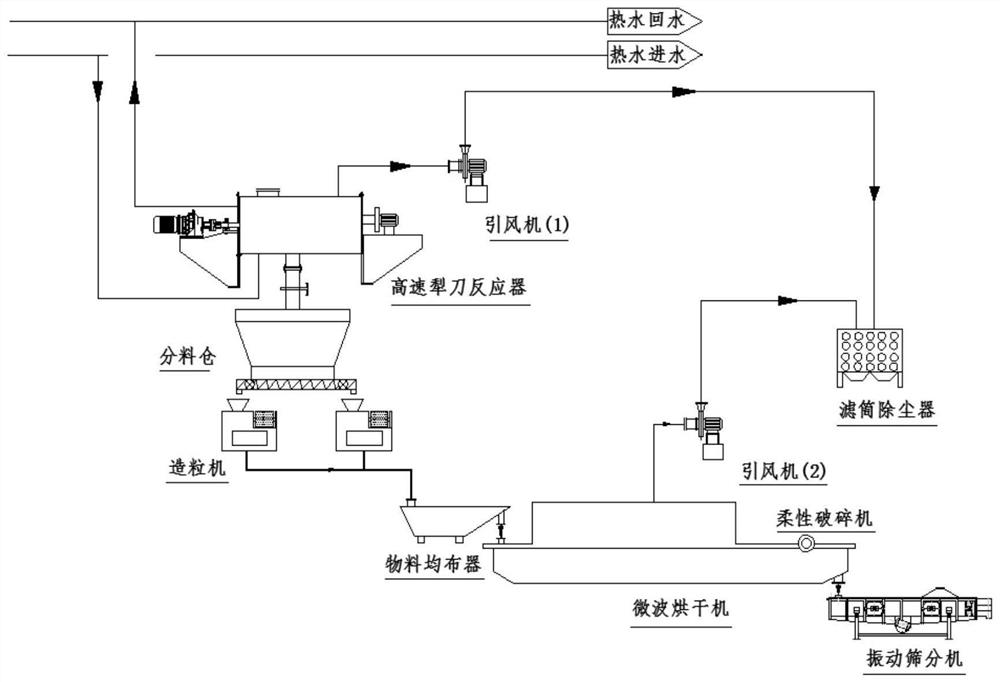

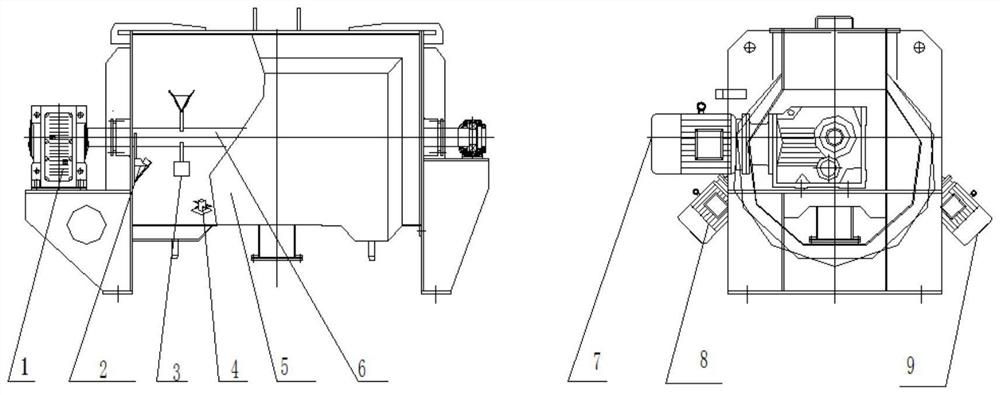

[0090] Adopt the system of the continuous production glyphosate ammonium salt granule described in the above-mentioned technical scheme, concrete work process is as follows:

[0091] First, check the mechanical integrity of all equipment in the system, turn on the first induced draft fan and the second induced draft fan, and debug all the equipment in the system to the pre-production state; Glyphosate raw powder, 18.5kg / batch of ammonium bicarbonate, 5.06kg / batch of ammonium sulfate, 5.06kg / batch of ammonium chloride, 0.41kg / batch of 9380 additive, 0.21kg / batch of RM15 additive, 0.21 Add kg / batch of pigments into the barrel of the high-speed coulter reactor for mixed reaction to obtain glyphosate ammonium salt; at the same time, the water vapor and dust generated during the above mixed reaction process are sent to the filter cartridge dust collector through the first induced draft fan Discharge after purification;

[0092] Then, the obtained glyphosate ammonium salt (the water-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com