Air compressor filter element cleaning method

An air compressor and filter element technology, which is applied in the field of compressor equipment, can solve the problem of rapid temperature rise of the filter element, and achieve the effects of preventing rapid temperature rise, simple structure, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

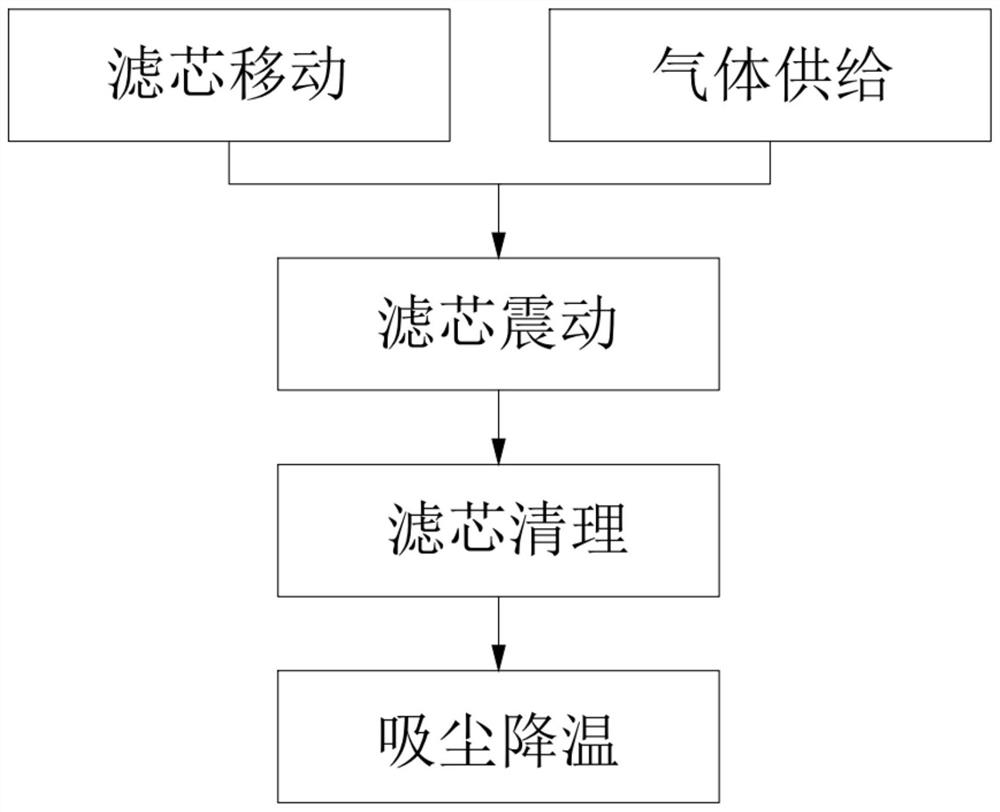

[0047] Such as figure 1 Shown, a kind of air compressor filter element cleaning method comprises the following steps:

[0048] Step 1: The filter element moves, the driving assembly 91 drives the rotating shaft 131 to rotate, and the rotating shaft 131 drives two sets of installation sleeves 151 to rotate so that the used filter element 14 and the clean filter element 14 are separated from the air outlet 7 and the air inlet respectively 6 and close the air outlet 7 and the air inlet 6;

[0049] Step 2: Gas supply is carried out synchronously with step 1. The rotating shaft 131 drives the rotating block 534 arranged in the control box 532 to rotate through the gear transmission assembly 52, and the air compressor outlet pipe and the air compressor inlet pipe and the cleaning assembly 51 are communicated, and the air compressor outlet pipeline carries out gas replenishment to the air compressor inlet pipeline, and the cleaning assembly 51 is inflated;

[0050] Step 3: The filt...

Embodiment 2

[0063] The present invention also provides an air compressor filter element cleaning system:

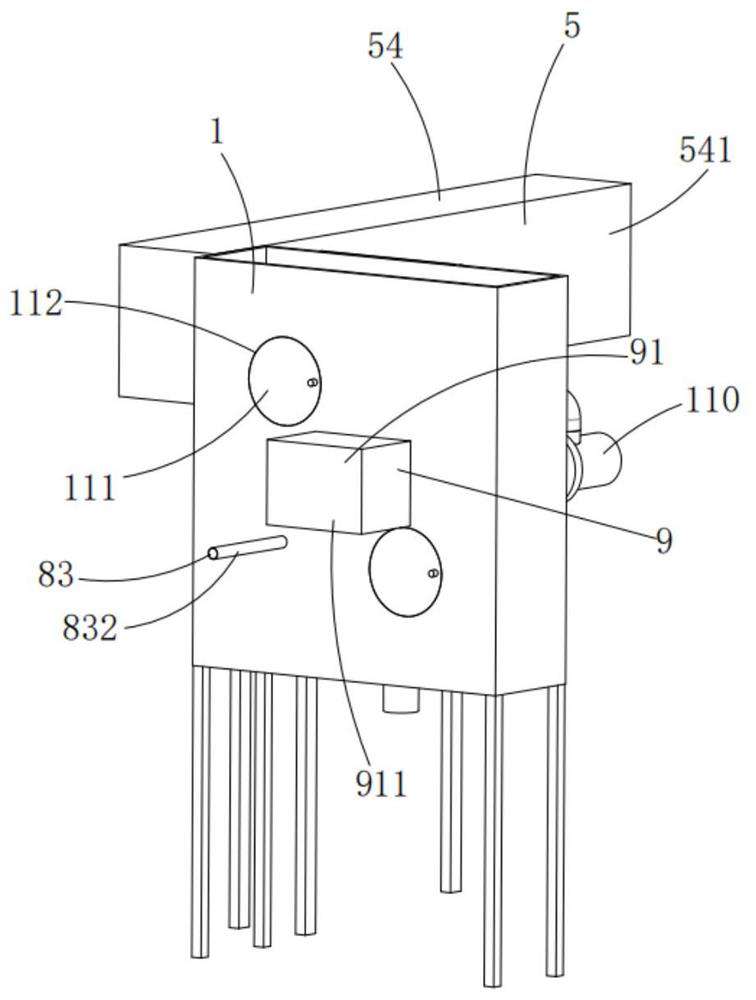

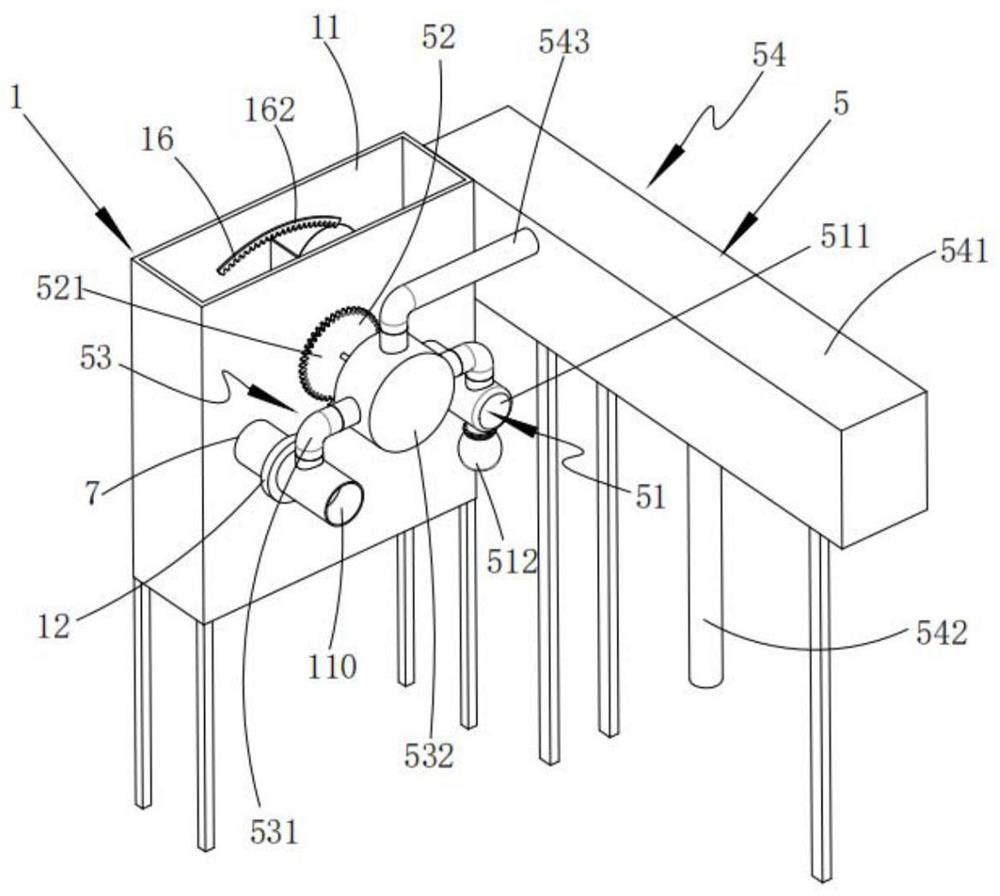

[0064] Such as Figure 2 to Figure 5 As shown, an air compressor filter element cleaning system includes:

[0065] Installation equipment 1, the installation equipment 1 includes a box body 11 provided with an air inlet 6 and an air outlet 7, a rotating assembly 13 installed in the box body 11, symmetrically and fixedly installed on the rotating assembly 13, and Two sets of installation assemblies 15 for installing the filter element 14 and a limit assembly 16 arranged corresponding to the installation assemblies 15 and driving the installation assemblies 15 to reciprocate and meridian; the air outlet 7 is connected to the air compressor air intake duct communication; the rotating assembly 13 rotates and drives two groups of the mounting assemblies 15 to align with the air inlet 6 and the air outlet 7 alternately;

[0066] Cleaning equipment 5, the cleaning equipment 5 includes a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com