Integrated single-fiber droplet manipulator

A manipulator, single-fiber technology, applied in the field of integrated single-fiber droplet manipulators, can solve the problems of inconvenient manipulation of biological droplets, complex external energy input, and reduced system life, and achieves the goal of promoting preparation and application research, high-efficiency Focusing power, easy-to-integrate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

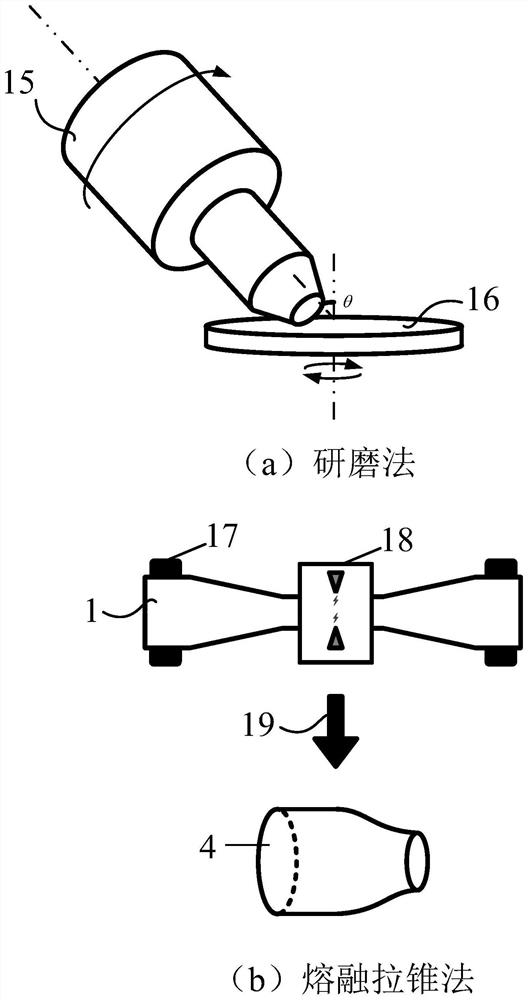

[0034] Step 1, the preparation of conical table fiber end (such as figure 2 shown). Method 1: Take a section of the dual-core optical fiber and fix it with the fiber clamp (15), and then place the fiber end on the grinding disc (16). The fiber clamp (15) and the fiber grinding disc (16) have their own DC motors. Connection, by controlling the optical fiber clamp (15) and the normal line of the grinding disc (16) to rotate at an angle of θ to prepare a conical table fiber end with an opening angle of θ; method two: fix the optical fiber with a movable clamping device (17) on the On the optical fiber tapering machine, it is melted under the high temperature heating of the fusion splicing unit (18), and stretched to both sides at the same time, through melting tapering to obtain vertebral bodies of different lengths, and then cutting to a fixed length at a suitable position in the tapering area (19), To prepare conical fiber ends with different opening angles;

[0035] Step 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com