Lightning arrester internal monitoring method and system

A monitoring system and lightning arrester technology, applied in the field of power supply, can solve the problems such as self-energy extraction of the arrester

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

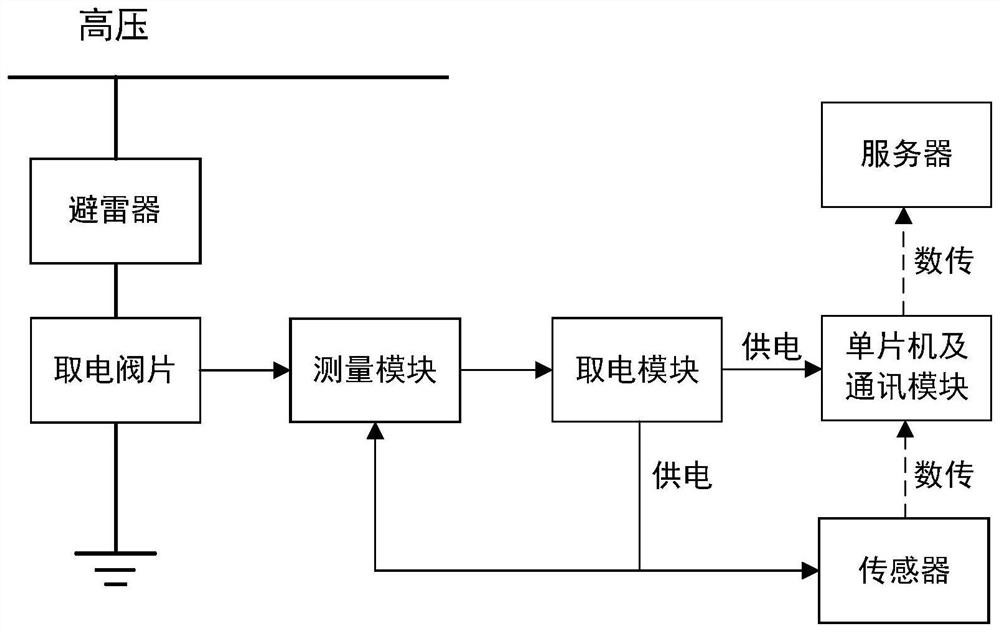

[0049]10kV built-in arrester monitoring system

[0050]The varistor voltage of the electrovalve 1 is 1kV, and the flow is 5kA;

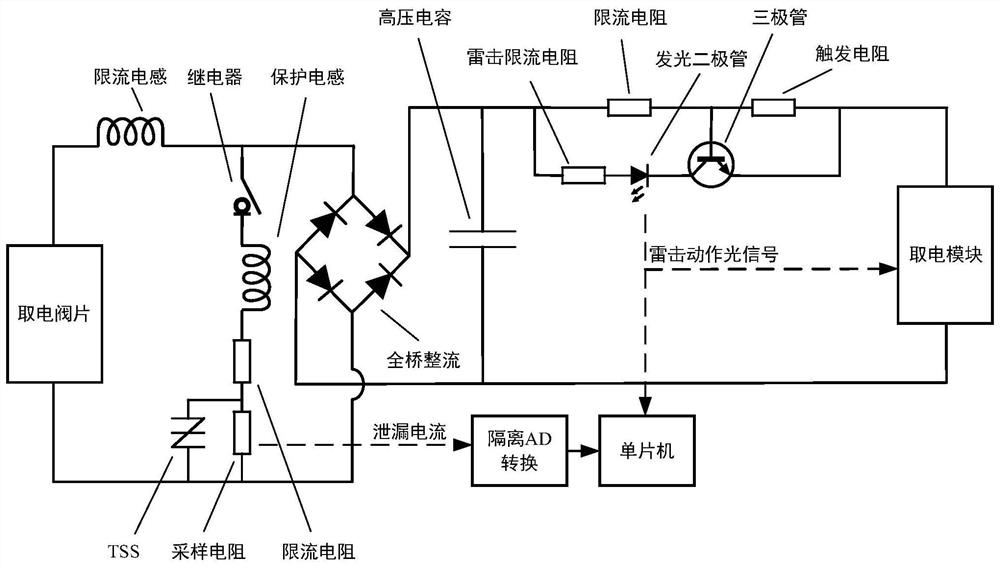

[0051]The measurement module 2 includes a small current measurement module and a lightning counting module.

[0052]The steady-state working input current of the power module 3 is 0~3mA, and the DC output is 5V.

[0053]The sensor 4 includes temperature, humidity and air pressure sensors.

[0054]The single-chip microcomputer and communication module 5 include MSP430 single-chip microcomputer and peripheral circuits, and NBIOT communication module.

[0055]The server 6 is the integrated automation system server in the substation.

[0056]Parts 1 to 5 of this 10kV line built-in arrester monitoring system are installed in the 10kV arrester cavity, which can measure the leakage current, operation information, internal temperature, humidity and air pressure data of the 10kV arrester and send it to the station automation system, and supply power independently through the leakage cu...

Embodiment 2

[0058]35kV built-in arrester monitoring system

[0059]The varistor voltage of the electrovalve 1 is 3kV, and the current is 10kA;

[0060]The measurement module 2 includes a small current measurement module and a lightning counting module.

[0061]The steady state working input current of the power module 3 is 0~5mA, and the DC output is 3.3V.

[0062]The sensor 4 includes temperature, humidity and air pressure sensors.

[0063]The single-chip microcomputer and communication module 5 include STM32 single-chip microcomputer and peripheral circuits, and 4G communication module.

[0064]Server 6 is a cloud server.

[0065]Parts 1 to 5 of this 35kV line built-in arrester monitoring system are installed in the 35kV arrester cavity, which can measure the 35kV arrester leakage current, operation information, internal temperature, humidity, and air pressure data and send it to the cloud server, and use the leakage current to supply power autonomously. Online monitoring, power acquisition and communication inte...

Embodiment 3

[0067]110kV built-in arrester monitoring system

[0068]The varistor voltage of the electrovalve 1 is 3kV, and the flow is 20kA;

[0069]The measurement module 2 includes a small current measurement module and a lightning counting module.

[0070]The steady state working input current of the power module 3 is 0-10mA, and the DC output is 12V.

[0071]The sensor 4 includes temperature, humidity and air pressure sensors.

[0072]The single-chip microcomputer and communication module 5 include MSP430 single-chip microcomputer and peripheral circuits, and a 5G communication module.

[0073]Server 6 is a cloud server.

[0074]Parts 1 to 5 of this 35kV line built-in arrester monitoring system are installed in the 35kV arrester cavity, which can measure the 35kV arrester leakage current, operation information, internal temperature, humidity, and air pressure data and send it to the cloud server, and use the leakage current to supply power autonomously. Online monitoring, power acquisition and communication int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com