Composite material with good thermal insulation effect and preparation method thereof

A technology of composite materials and heat insulation effect, which is applied in heat exchange equipment, pipeline protection through heat insulation, mechanical equipment, etc., can solve problems such as limited heat insulation effect, poor compression resistance, single heat insulation of heat insulation materials, etc. Achieve good heat insulation effect, improve overall compressive capacity, and poor heat transmission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

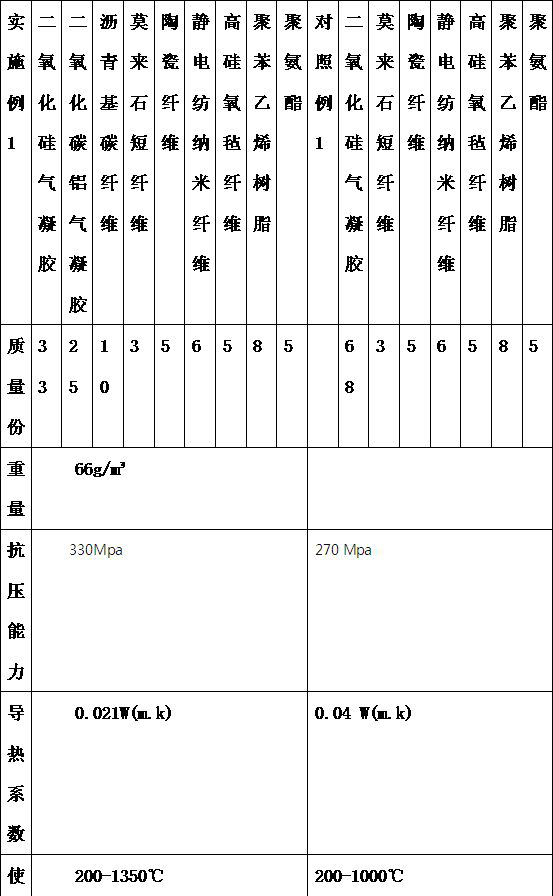

Embodiment 1

[0039] A composite material with good heat insulation effect and a preparation method thereof, comprising a heat insulation substrate, a heat insulation reinforcing rib, a heat insulation inner core and a heat insulation fiber composite coating, characterized in that the heat insulation substrate is a carbon-carbon composite plate, and the heat insulation The thermal reinforcement is a carbon-carbon composite column, the heat-insulating inner core is polyurethane foam, and the heat-insulating fiber composite coating is composed of the following raw materials: 33 parts by mass of silica airgel; 25 parts by mass of carbon dioxide aluminum airgel; pitch-based carbon fiber 10 parts by mass; 3 parts by mass of mullite short fiber; 5 parts by mass of ceramic fiber; 6 parts by mass of electrospun nanofiber; 5 parts by mass of high-silica felt fiber; 8 parts by mass of polystyrene resin; 5 parts by mass of polyurethane.

[0040] The preparation method in the present embodiment comprise...

Embodiment 2

[0047] A composite material with good heat insulation effect and a preparation method thereof, comprising a heat insulation substrate, a heat insulation reinforcing rib, a heat insulation inner core and a heat insulation fiber composite coating, characterized in that the heat insulation substrate is a carbon-carbon composite plate, and the heat insulation The thermal reinforcement is a carbon-carbon composite column, the heat-insulating inner core is polyurethane foam, and the heat-insulating fiber composite coating is composed of the following raw materials: 33 parts by mass of silica airgel; 25 parts by mass of carbon dioxide aluminum airgel; pitch-based carbon fiber 7 parts by mass; 4 parts by mass of mullite short fiber; 5 parts by mass of ceramic fiber; 6 parts by mass of electrospun nanofiber; 5 parts by mass of high-silica felt fiber; 10 parts by mass of polystyrene resin; 5 parts by mass of polyurethane.

[0048] The preparation method in the present embodiment comprise...

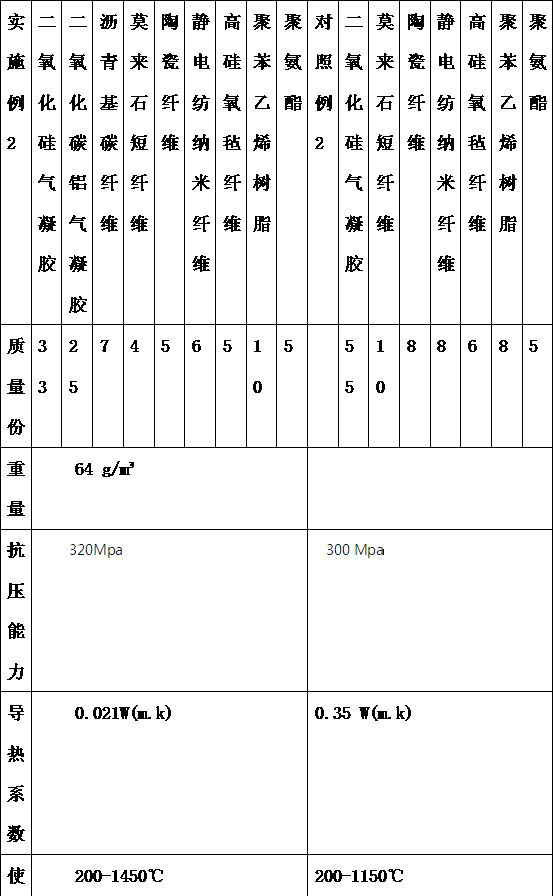

Embodiment 3

[0055] A composite material with good heat insulation effect and a preparation method thereof, comprising a heat insulation substrate, a heat insulation reinforcing rib, a heat insulation inner core and a heat insulation fiber composite coating, characterized in that the heat insulation substrate is a carbon-carbon composite plate, and the heat insulation The thermal reinforcement is a carbon-carbon composite column, the heat-insulating inner core is polyurethane foam, and the heat-insulating fiber composite coating is composed of the following raw materials: 33 parts by mass of silica airgel; 20 parts by mass of carbon dioxide aluminum airgel; pitch-based carbon fiber 7 parts by mass; 4 parts by mass of mullite short fiber; 5 parts by mass of ceramic fiber; 6 parts by mass of electrospun nanofiber; 5 parts by mass of high-silica felt fiber; 11 parts by mass of polystyrene resin; 9 parts by mass of polyurethane.

[0056] The preparation method in the present embodiment comprise...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com