Building pipe pile with built-in reinforcing ribs

A technology of reinforcing bars and pipe piles, which is applied in construction, sheet pile wall, foundation structure engineering, etc., can solve the problems of affecting strength, difficult to quickly solidify and form, and achieve the advantages of increasing mechanical strength, increasing overall mechanical strength, and improving production speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

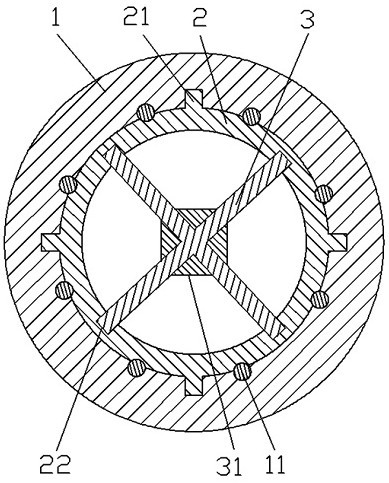

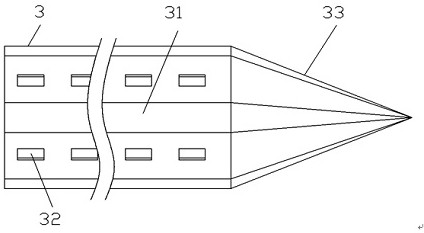

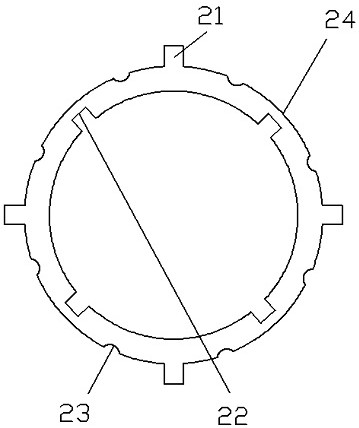

[0023] Such as Figure 1~3 As shown, the scheme of the present invention provides a construction pipe pile with built-in reinforcing ribs, comprising a pipe pile outer layer 1, a supporting inner pipe 2 and a reinforcing rib group 3, the inner wall of the pipe pile outer layer 1 is fixedly connected with a supporting inner pipe 2, and the supporting The inner wall of the inner tube 2 is detachably connected with a reinforcing rib group 3, and the outer wall of the supporting inner tube 2 is fixedly connected with four fixed ribs 21 centered on the center of the supporting inner tube 2. The inner wall of the supporting inner tube 2 is provided with four ribs to support the inner The center of the tube 2 is a positioning groove 22 distributed in a central ring, the inner wall of the positioning groove 22 is slidably connected with a reinforcing rib group 3 , and one end of the reinforcing rib group 3 has a guide head 33 .

[0024] In this embodiment: the inner wall of the suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com