High-solid-content and low-viscosity polyaspartic acid ester primer-topcoat coating suitable for high-pressure airless spraying and preparation method thereof

An aspartic acid ester, high-pressure airless technology, applied in the field of coatings, can solve the problems of pinholes, fast reaction speed, short pot life, etc., and achieve the effect of long pot life, high salt spray resistance, and reduced winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

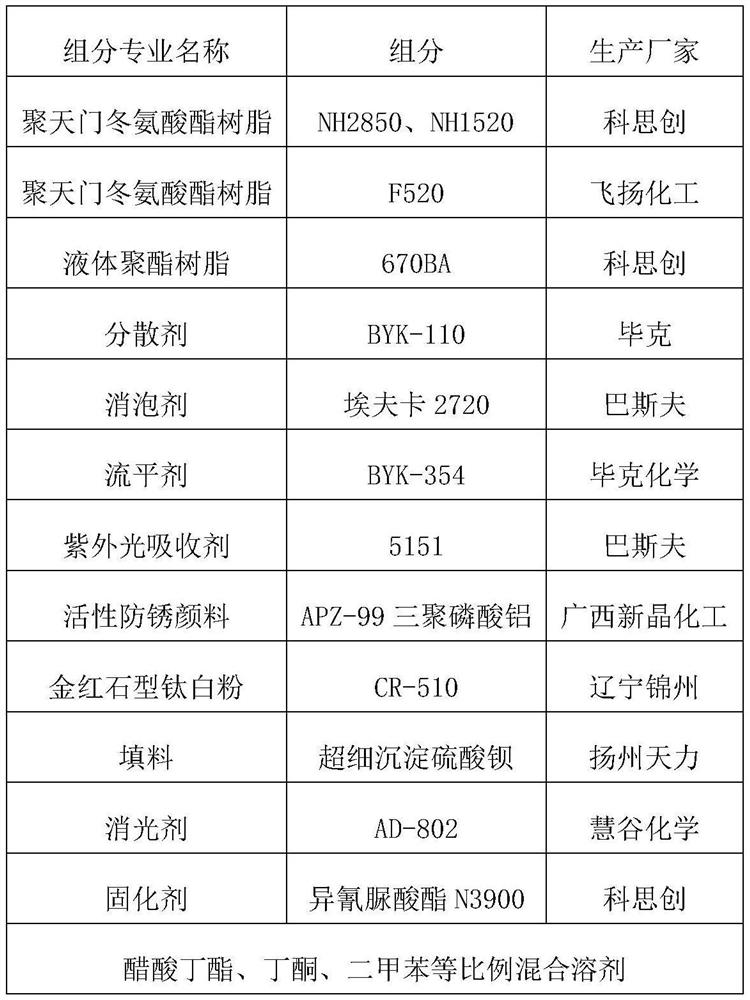

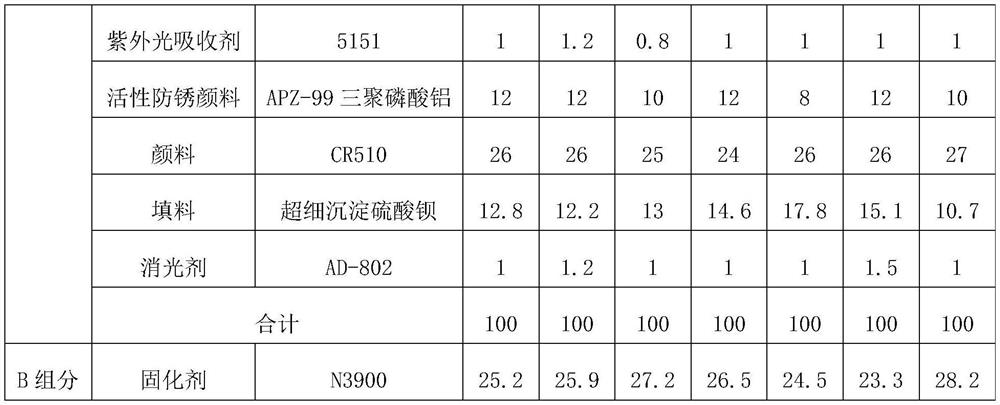

[0029] Example 1 According to the raw materials and proportions described in Table 2, add 8g of mixed solvent in the batching tank, add polyaspartic acid ester resin NH2850 10g, NH1520 8g, F520 6g, liquid polyester resin 670BA 14g, dispersant under stirring 0.4g, defoamer 0.3g, leveling agent 0.5g, dehydrating agent, low-speed stirring and dispersion for 5-10min, under the condition of stirring, add appropriate amount of TSC-2 titanate coupling agent to activate the polar group, about 30min. Then add 26g of pigment CR510 titanium dioxide, 12g of active anti-rust pigment APZ-99, 12.8g of superfine natural barium sulfate while stirring, stir at high speed for 20-30min, stand still for 30min, remove the moisture in the solvent and pigments and fillers; pump the materials into Sand mill with sand mill until the paint fineness is less than or equal to 45um, discharge the material, then add 1g of UV absorber and 1g of AD-802 matting agent, stir evenly, adjust the color, adjust the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com