Preparation method of oil-based polyurethane slow-release nitrogen fertilizer

A polyurethane and nitrogen fertilizer technology, applied in nitrogen fertilizer, fertilization equipment, urea compound fertilizer, etc., can solve the problems of uneven nutrient release, coating uniformity and controllability, high cost, etc., to prolong the nutrient release cycle and improve chemical efficiency. Stability, effects of avoiding agricultural costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

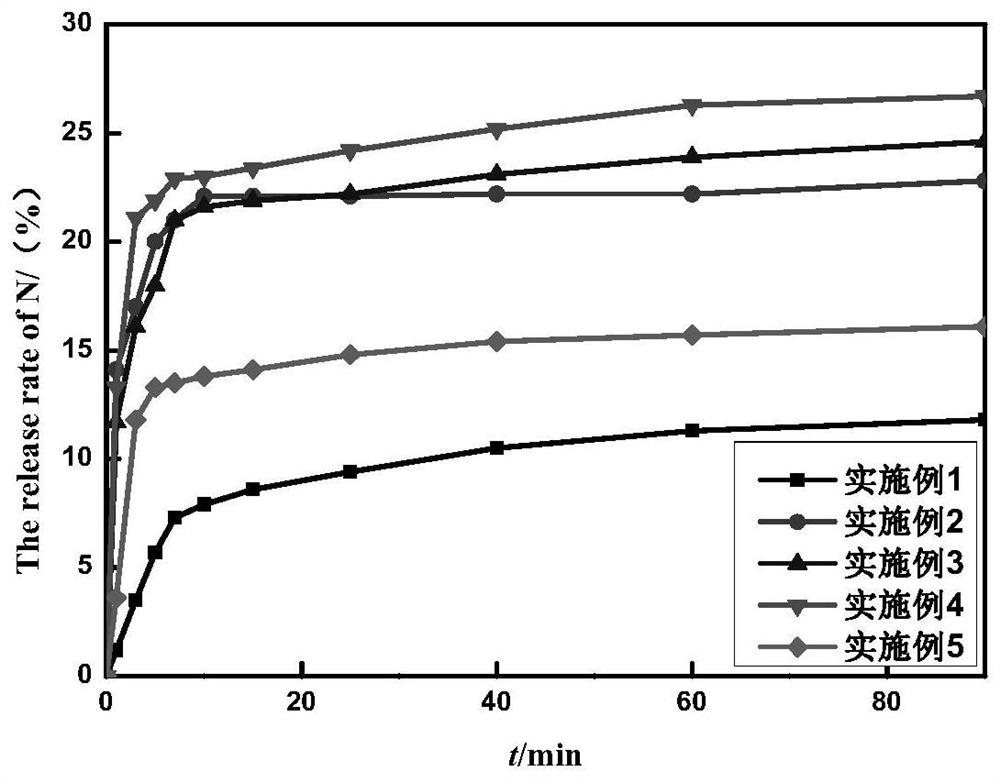

Embodiment 1

[0036] Weigh 25 parts of large particle urea, 1.5 parts of ZnO (urea precipitation method) catalyst and 25 parts of castor oil in a flask, heat it to a reaction temperature of 70 °C, and feed inert gas N 2 , the flow rate was controlled at 100mL / min, and the reaction was carried out for 5h without stirring. Subsequently, the grafted urea was collected, placed in a beaker, 12.5 parts of ethylenediamine was added, and the polymerization reaction was carried out at room temperature (25°C). The reaction time was 2h. The coated urea was taken out and dried naturally overnight, and finally dried at 40°C for 24h. , to obtain polyurethane-coated urea slow-release fertilizer.

[0037] Slow-release performance test: use p-dimethylaminobenzaldehyde color spectrophotometry to detect the content of urea in the aqueous solution of polyurethane slow-release nitrogen fertilizer, and then know the slow-release performance of the fertilizer. The method is as follows: Take 5.00g of polyurethane...

Embodiment 2

[0039] Weigh 25 parts of large particle urea, 1.5 parts of ZnO (roasted zinc nitrate) catalyst and 25 parts of castor oil in a flask, heat it to a reaction temperature of 70 ° C, and feed inert gas N 2 , the flow rate was controlled at 100mL / min, and the reaction was carried out for 5h without stirring. Subsequently, the grafted urea was collected, placed in a beaker, 12.5 parts of ethylenediamine was added, and the polymerization reaction was carried out at room temperature. The reaction time was 2 hours. The coated urea was taken out and dried naturally overnight, and finally dried at 40°C for 24 hours to obtain polyurethane coated Cover with urea slow-release fertilizer.

[0040] Performance testing method is as embodiment 1

Embodiment 3

[0042]Weigh 25 parts of large particle urea, 1.5 parts of ZnO (roasted zinc oxalate) catalyst and 25 parts of castor oil in a flask, heat to the reaction temperature of 70 ° C, and pass inert gas N 2 , the flow rate was controlled at 100mL / min, and the reaction was carried out for 5h without stirring. Subsequently, the grafted urea was collected, placed in a beaker, 12.5 parts of ethylenediamine was added, and the polymerization reaction was carried out at room temperature. The reaction time was 2 hours. The coated urea was taken out and dried naturally overnight, and finally dried at 40°C for 24 hours to obtain polyurethane coated Cover with urea slow-release fertilizer.

[0043] Performance testing method is as embodiment 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com