Automatic bobbin changing device of non-woven fabric winding machine

A technology of winding machine and non-woven fabric, which is applied in the field of non-woven fabric production, and can solve problems such as parts damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

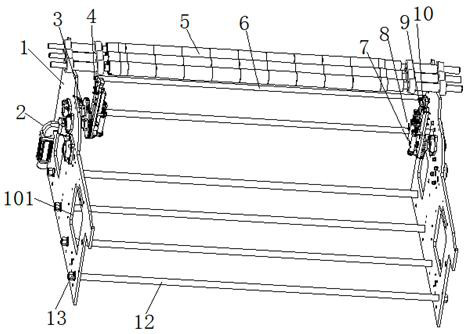

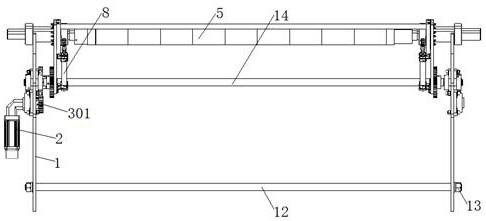

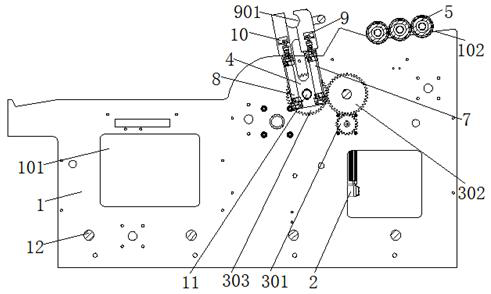

[0033] refer to Figure 1-3 , an automatic can changing device for a non-woven fabric winding machine, comprising a wallboard 1, the wallboard 1 is provided with two identical ones, and the automatic can changing device for a non-woven fabric winding machine also includes:

[0034] The winding drum 5 is arranged on the top of the wallboard 1, and its two ends are respectively against the top outer walls of the two wallboards 1;

[0035] The gear group 3 is provided with two groups, and is respectively connected to the two wall panels 1;

[0036] The cylinder changing swing arm 4 is connected to the gear set 3 and cooperates with the gear set 3;

[0037] The first cylinder 7 and the second cylinder 8 are both fixedly connected to the canister changing swing arm 4;

[0038] The first slider 9 and the second slider 10 are respectively connected to the output ends of the first cylinder 7 and the second cylinder 8;

[0039] Wherein, the first slider 9 is further provided with a ...

Embodiment 2

[0043] refer to Figure 1-3 , an automatic can changing device for a non-woven fabric winding machine, comprising a wallboard 1, the wallboard 1 is provided with two identical ones, and the automatic can changing device for a non-woven fabric winding machine also includes:

[0044] The winding drum 5 is arranged on the top of the wallboard 1, and its two ends are respectively against the top outer walls of the two wallboards 1;

[0045] The gear group 3 is provided with two groups, and is respectively connected to the two wall panels 1;

[0046] The cylinder changing swing arm 4 is connected to the gear set 3 and cooperates with the gear set 3;

[0047] The first cylinder 7 and the second cylinder 8 are both fixedly connected to the canister changing swing arm 4;

[0048] The first slider 9 and the second slider 10 are respectively connected to the output ends of the first cylinder 7 and the second cylinder 8;

[0049] Wherein, the first slider 9 is further provided with a ...

Embodiment 3

[0054] refer to Figure 1-3 , an automatic can changing device for a non-woven fabric winding machine, comprising a wallboard 1, the wallboard 1 is provided with two identical ones, and the automatic can changing device for a non-woven fabric winding machine also includes:

[0055] The winding drum 5 is arranged on the top of the wallboard 1, and its two ends are respectively against the top outer walls of the two wallboards 1;

[0056] The gear group 3 is provided with two groups, and is respectively connected to the two wall panels 1;

[0057] The cylinder changing swing arm 4 is connected to the gear set 3 and cooperates with the gear set 3;

[0058] The first cylinder 7 and the second cylinder 8 are both fixedly connected to the canister changing swing arm 4;

[0059] The first slider 9 and the second slider 10 are respectively connected to the output ends of the first cylinder 7 and the second cylinder 8;

[0060] Wherein, the first slider 9 is further provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com