Spiral conveyor for quickly cooling needle coke high-temperature powder

A screw conveyor, rapid cooling technology, applied in the direction of conveyor objects, transportation and packaging, cleaning devices, etc., can solve the problems of adjusting the feeding hopper, inconvenient, inconvenient adjustment, etc., to increase the volume and improve the feeding efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

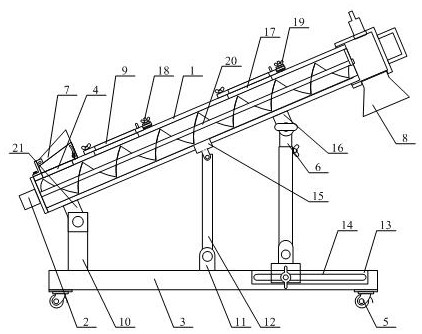

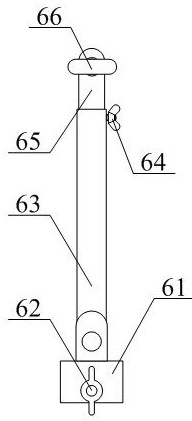

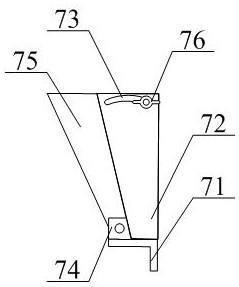

[0037] The present invention is described in detail below in conjunction with accompanying drawing, as appended figure 1 And attached figure 2 As shown, a screw conveyor for rapid cooling of needle coke high-temperature powder, including a feeding pipe 1, a feeding motor 2, a moving base 3, a feeding port 4, a moving brake wheel 5, and an adjustable sliding support rod Structure 6, rotatable and adjustable upper hopper structure 7, detachable adding conveying cover structure 8, observable cleaning cover structure 9, support column 10, connecting seat 11, support rod 12, chute 13, slide hole 14, U-shaped socket Seat 15, inverted U-shaped socket seat 16, cleaning hole 17, fixed rod 18, wing nut 19, spiral dragon rod 20 and rotating seat 21, and the described feeding motor 2 bolts are connected to the left side of feeding pipe 1 middle position; the feed inlet 4 is set on the left side of the upper end of the feeding pipe 1; the mobile brake wheels 5 are respectively bolted to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com