Partitioned grinding equipment for spherical base surfaces of bearing rollers

A bearing roller and ball base surface technology, applied in the field of bearing roller ball base surface zone grinding equipment, can solve the problems of poor dimensional stability, large dimensional deviation, low production efficiency, etc., and achieve high dimensional stability and R angle deviation. Small size, the effect of improving dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Preferred embodiments of the present invention are described below with reference to the accompanying drawings. Those skilled in the art should understand that these embodiments are only used to explain the technical principles of the present invention, and are not intended to limit the protection scope of the present invention.

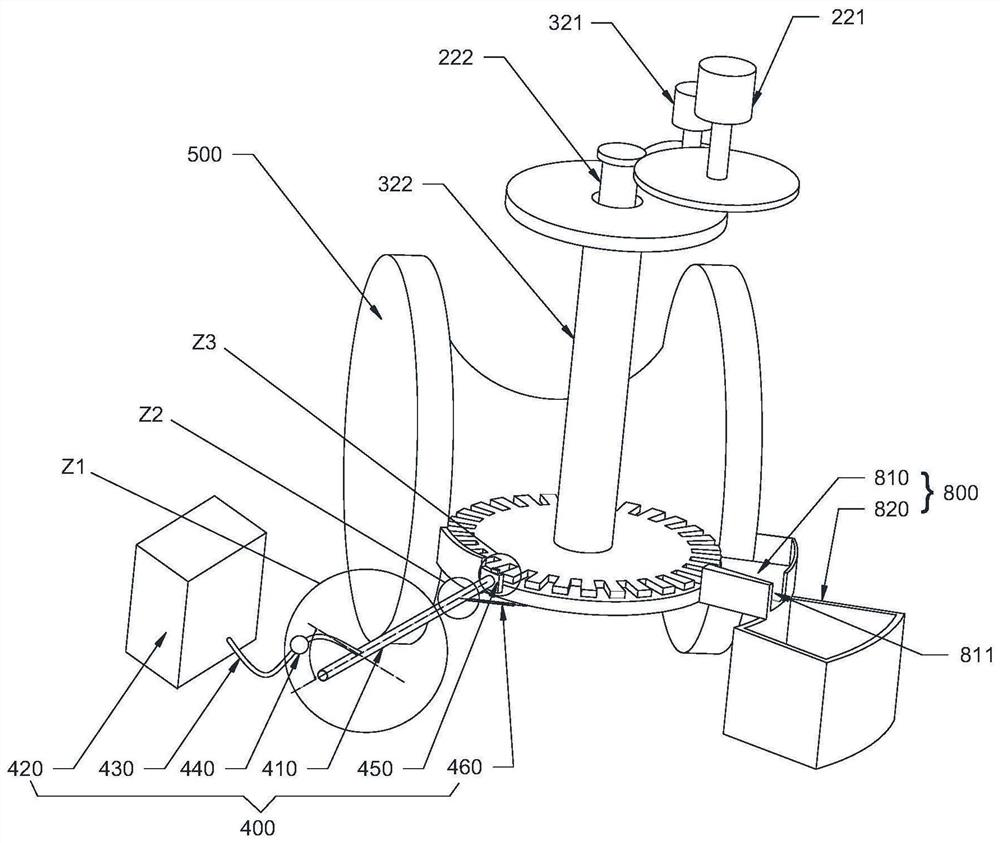

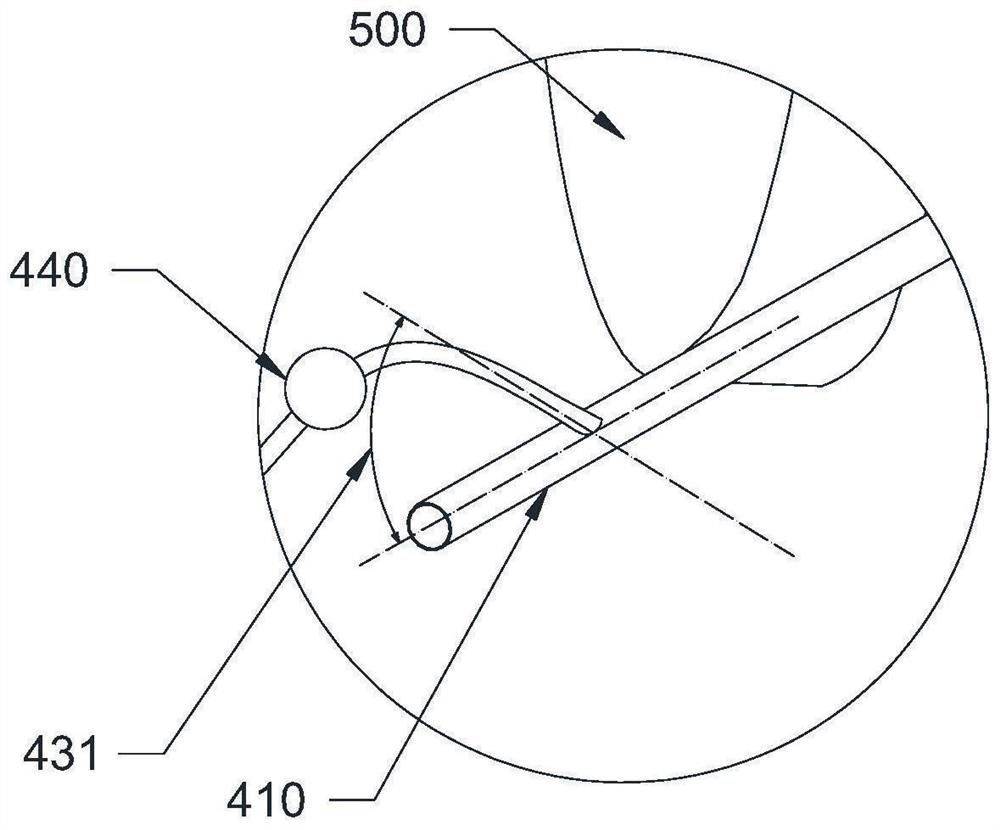

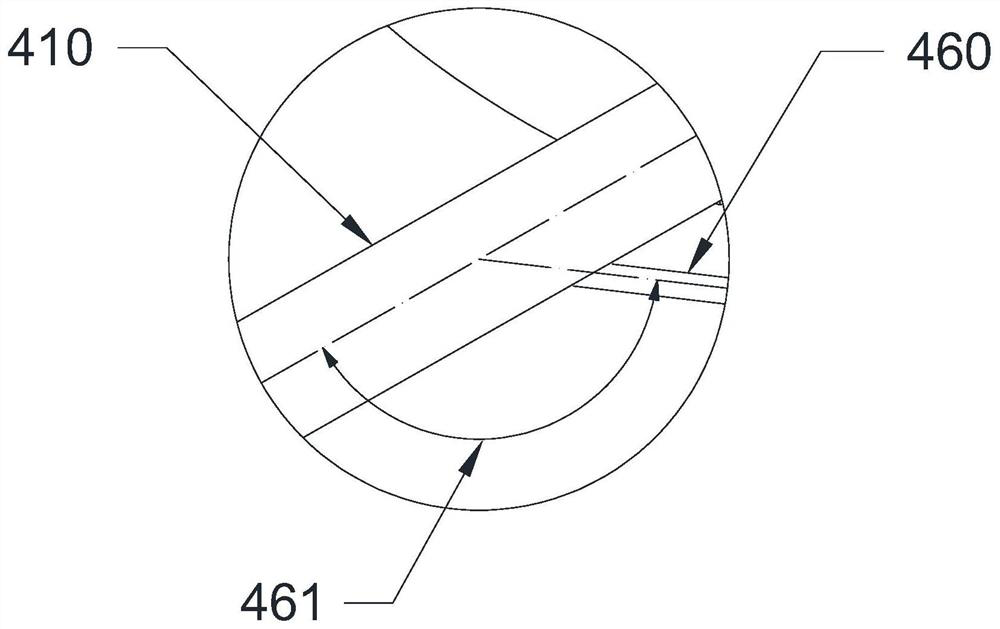

[0058] see Figure 1 to Figure 12 , an embodiment of the present invention provides a bearing roller ball base surface partition grinding equipment, which includes:

[0059] Rack (not shown in the figure);

[0060] The revolving mechanism 200, the revolving mechanism includes a revolving disk 210 and a first power assembly 220 that drives the revolving disk to be rotatably installed on the frame, the revolving disk is provided with at least two receiving grooves 211, the The openings of at least two accommodation grooves are away from the axis of the revolving disk, the at least two accommodation grooves are evenly arranged on the peripheral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com