Laser welding shielding gas device

A laser welding and shielding gas technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of small shielding gas coverage, burning laser welding head, annular gas cover failure, etc., to maintain process stability The effect of improving the welding speed, uniform and stable air flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

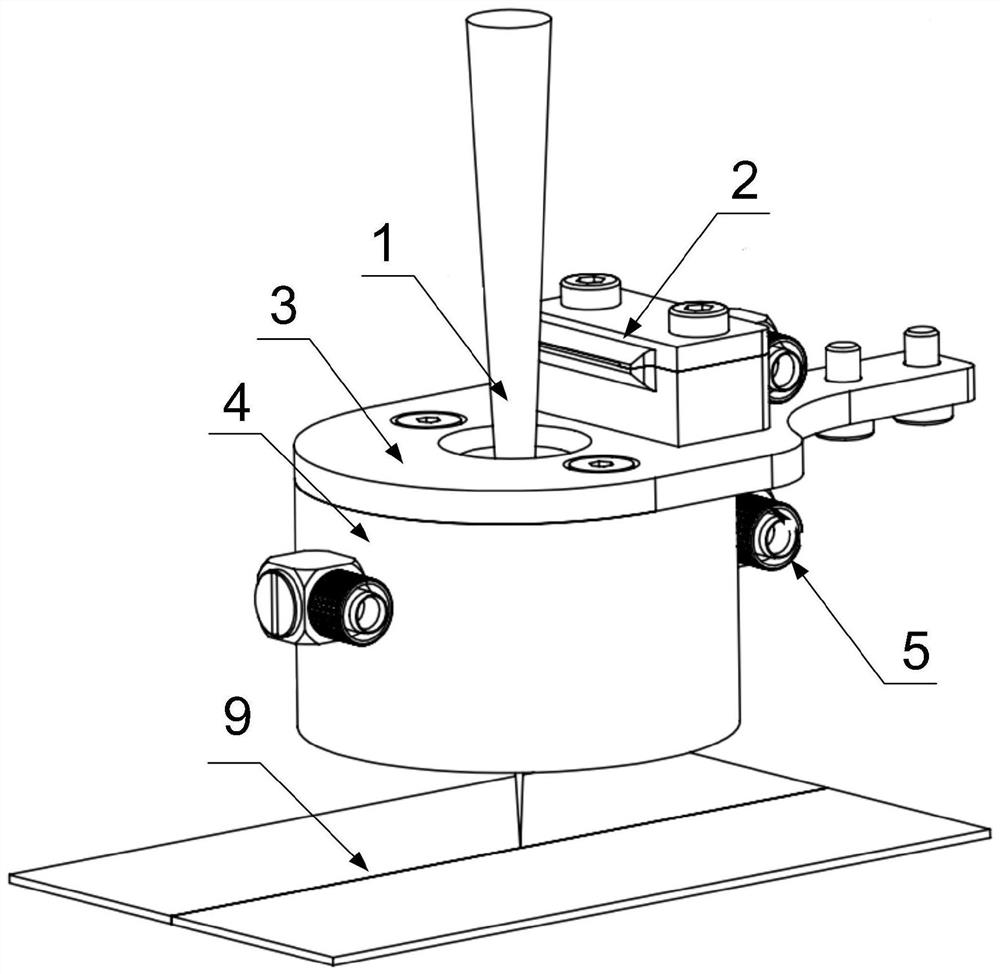

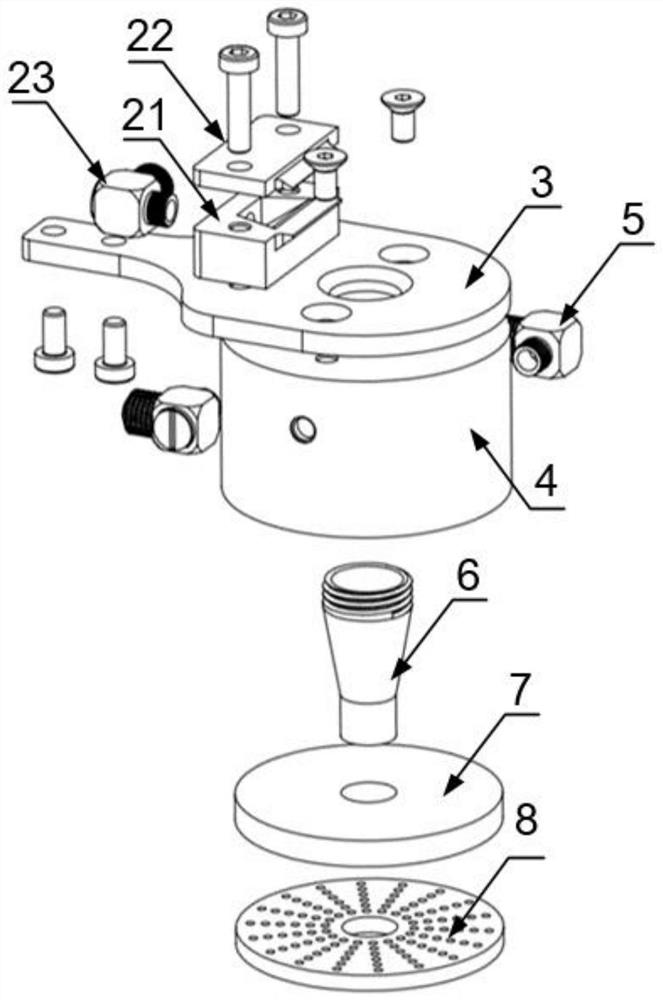

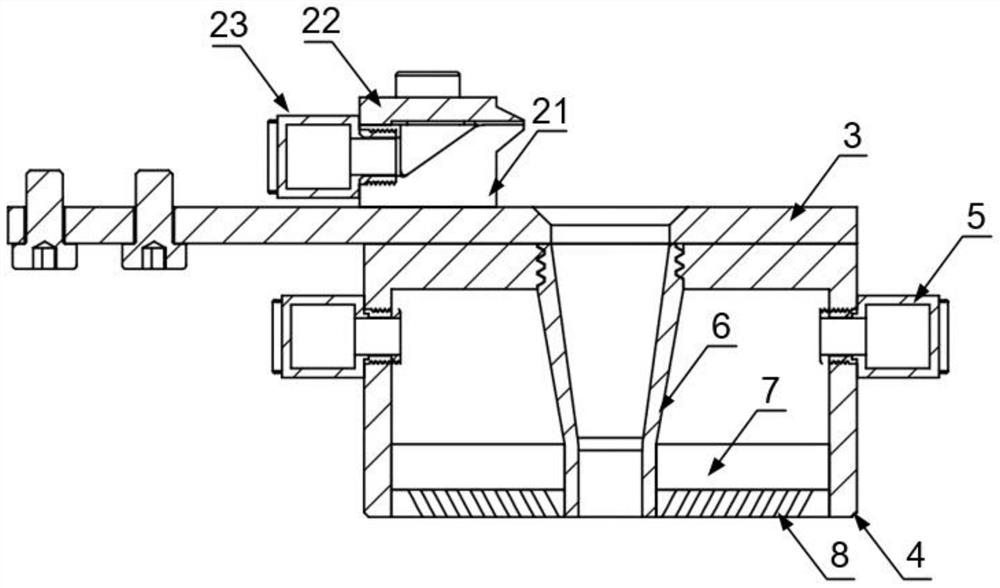

[0035] see Figure 1-5 , a shielding gas device for laser welding, including an air knife assembly 2, a connecting bracket 3, an air cavity 4, an air cavity trachea joint 5, a high temperature resistant nozzle 6, a gas homogenizing filter plate 7, and an air flow guide plate 8.

[0036] Such as figure 1 As shown, the air knife assembly 2 is detachably installed on the connecting bracket 3; the air cavity 4 is a cylindrical structure with one side open, with the opening facing downwards (see image 3 ), its top is connected with the connecting bracket 3 by screws, and the outside of the air chamber 4 is provided with an air inlet, and the air inlet and the air chamber trachea joint 5 are connected by threads. Such as figure 2 , image 3 As shown, the high temperature resistant nozzle 6 is a conical cylindrical structure with upper and lower openings, the upper end of the high temperature resistant nozzle 6 is threadedly connected to the through hole in the middle of the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com