Desmear device for production of circuit board for automobile rearview mirror control switch

A technology for automotive rearview mirrors and control switches, which is applied to the secondary treatment of printed circuits, cleaning methods using liquids, cleaning methods and appliances, etc., which can solve the problems of increasing manufacturing costs, reducing the service life of potassium permanganate, and preventing liquid drops Problems such as falling on the outside of the box can be quickly cleaned, the service life is improved, and the efficiency of removing slag is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

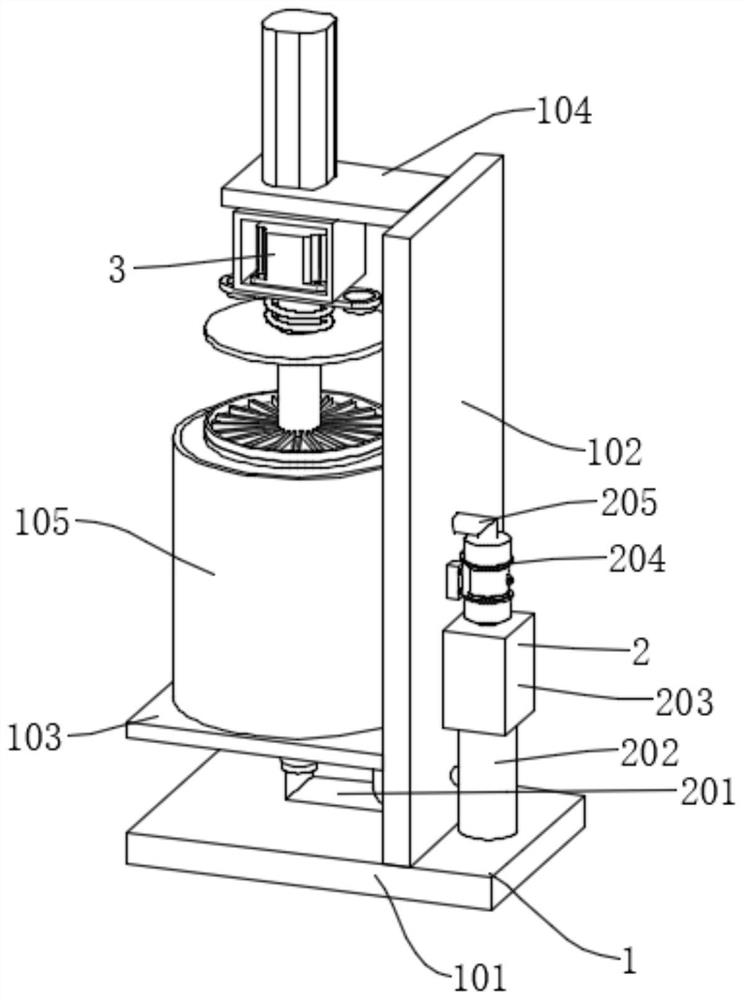

[0037] like Figure 1-7 As shown in the figure, the glue removal device produced by the circuit board for the control switch of the automobile rearview mirror includes the device body 1. The device body 1 is mainly composed of a bottom plate 101, a vertical plate 102, a support plate 103, a top plate 104, and a box body 105. It also includes Auxiliary mechanism 2, material placement mechanism 3, auxiliary mechanism 2 includes water pipe 201, impurity removal component 202, electrolysis box 203, water pump 204, and return pipe 205. Over the vertical plate 102, and connected with the impurity removal assembly 202 through the throat hoop, the top of the impurity removal assembly 202 is communicated with the electrolysis box 203, the top of the electrolysis box 203 is connected with the water inlet end of the water pump 204, and the water outlet end of the water pump 204 is connected with a return flow through the throat hoop Pipe 205, the end of the return pipe 205 away from the ...

Embodiment 2

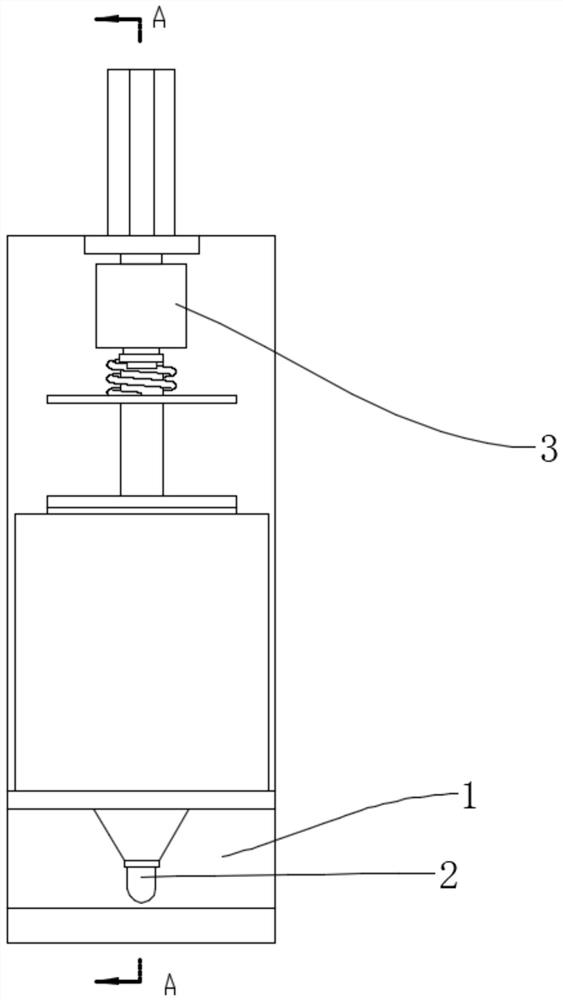

[0040] like Figure 8 As shown, Embodiment 2 differs from Embodiment 1 in that a connecting plate 311 is welded on the outside of the rotating shaft 304, a lead screw 314 is threadedly connected at both ends of the connecting plate 311, and the lower end of the lead screw 314 is connected to the top of the pressing plate 305 through a bearing, In this way, by rotating the lead screw 314, under the action of the connecting plate 311, the lead screw 314 is lowered, and the lead screw 314 drives the rotating head 315 to descend, so that the pressing plate 305 presses the circuit board more firmly, and can also be rotated in the opposite direction. The lead screw 314, under the action of the connecting plate 311, makes the lead screw 314 rise, and the lead screw 314 drives the rotating head 315 to rise, so that the pressure plate 305 is separated from the circuit board, which facilitates the removal of the circuit board. The top of the lead screw 314 is welded with a rotating head ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com