Circuit breaker

A technology of circuit breakers and elastic parts, applied in the field of circuit breakers, can solve problems such as arc restrike, poor reliability, and easy failure, and achieve the effects of reducing energy release, increasing service life, and reducing operating frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

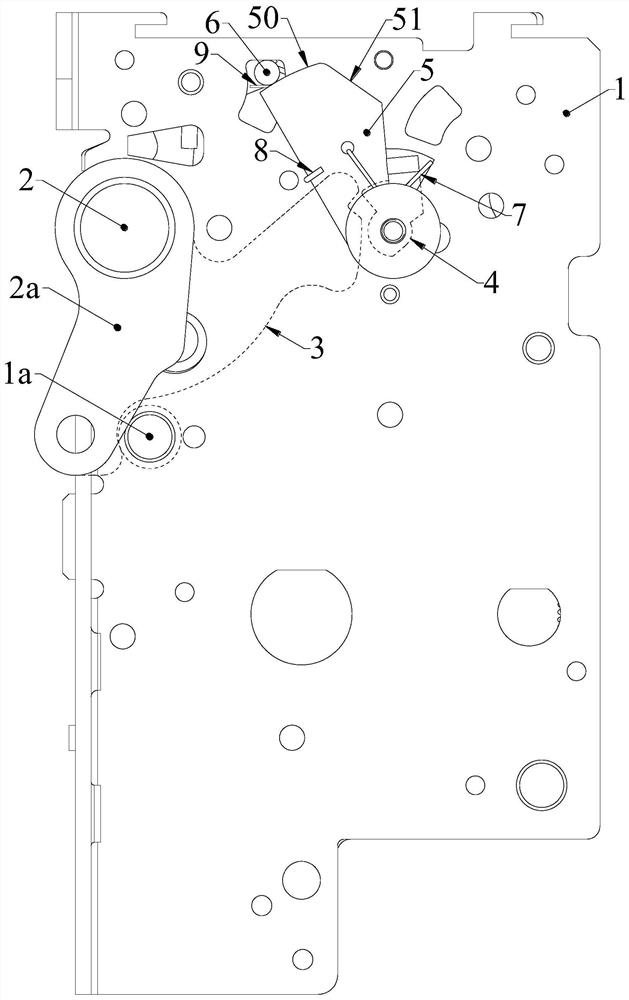

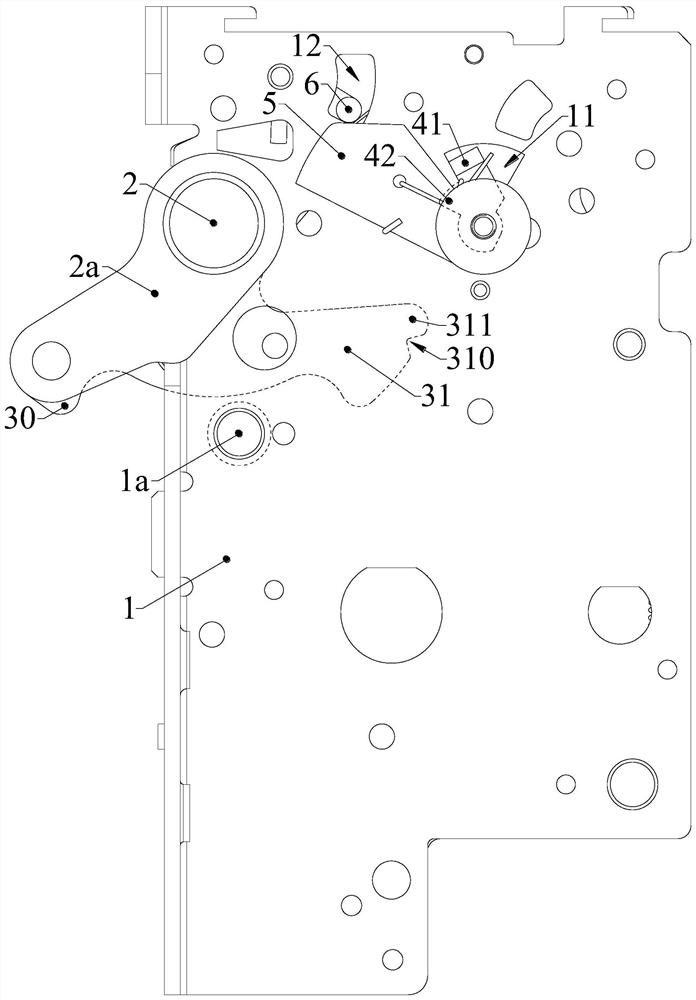

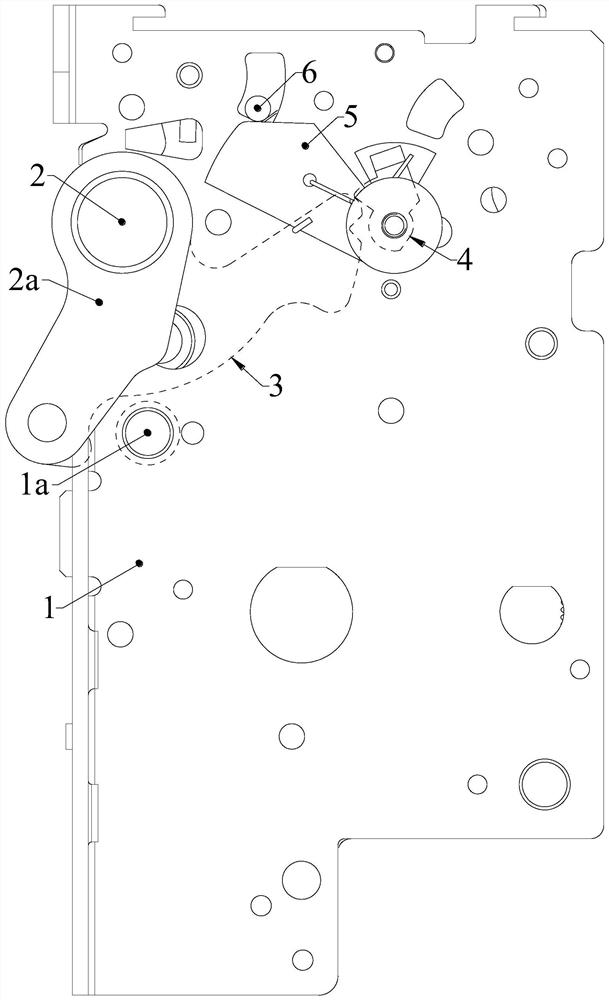

[0032] The following is attached Figure 1-10 The given examples further illustrate the specific implementation of the circuit breaker of the present invention. The circuit breaker of the present invention is not limited to the description of the following embodiments.

[0033] Such as Figure 1-6 Shown is an embodiment of the circuit breaker of the present invention.

[0034] The circuit breaker of the present invention includes a side plate assembly 1, a main shaft 2, a stop shaft 1a, a stop cantilever 3 and an opening semi-shaft 6. The side plate assembly 1 includes two side plates arranged at opposite intervals, and the two ends of the main shaft 2 are respectively Cooperating with the rotation of the two side plates, the stop cantilever 3 is arranged on the main shaft 2 to rotate synchronously with it, and the two ends of the stop shaft 1a are respectively arranged on the two side plates; the circuit breaker also includes an anti-rebound mechanism to prevent rebound Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com