Circuit of self-excited oscillation voltage-multiplying and constant-current control electromagnetic valve and gas stove using same

A technology of constant current control and self-excited oscillation, applied in the field of solenoid valves, can solve the problems of declining brand quality, high hardware cost, waste of peripheral component resources, etc., to reduce hardware costs, reduce peripheral components, and improve product reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

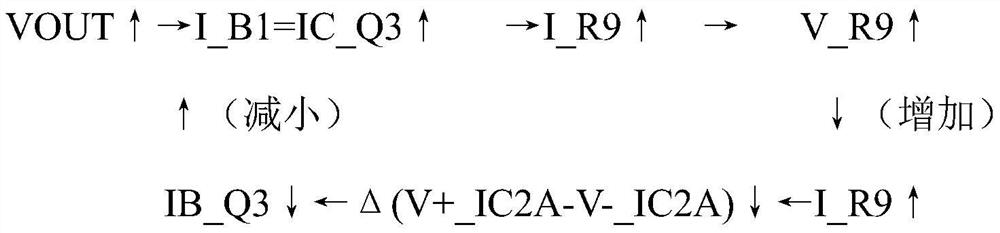

[0024] Embodiments of the present invention provide a self-oscillating voltage doubling and constant current control solenoid valve circuit, such as figure 1 As shown, it includes a self-excited oscillation module 1, a full-wave rectification module 2 and a negative feedback amplification module 3, the self-excited oscillation module 1 is electrically connected to the full-wave rectification module 2, and the full-wave rectification module 2 is electrically connected to the negative feedback amplification module 3. The self-excited oscillation module 1 is used to generate a PWM signal, the full-wave rectification module 2 is used to output a voltage doubler drive voltage according to the PWM signal generated by the self-excited oscillation module 1, and the negative feedback amplification module 3 is used to output The voltage doubler driving voltage of the full-wave rectification module 2 is negatively fed back and constant current output controls the solenoid valve.

[0025]...

Embodiment 2

[0047] Embodiment 2 of the present invention provides a gas cooker, which includes the self-oscillating circuit for voltage doubling and constant current control of the solenoid valve.

[0048] In the gas cooker of the present invention, the PWM signal is first generated by the self-excited oscillation module, then the voltage doubling driving voltage is output by the full-wave rectification module according to the PWM signal of the self-excited oscillation module, and finally the voltage doubled by the full-wave rectification module is output by the negative feedback amplification module. The driving voltage negative feedback constant current output controls the solenoid valve, so as to realize the stable output of the solenoid valve by means of self-excited oscillation voltage doubler + constant current control, abandon the control of switching power supply chip, reduce the peripheral components, reduce the hardware cost in the design process, and realize Steady injection of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com