Insulating rubber hose forming detection system and detection method

A detection system, a technology of insulating rubber, applied in the direction of detecting the appearance of fluid at the leak point, using liquid/vacuum for liquid tightness measurement, etc., can solve the problems of rubber hose conduction, increased workload, low work efficiency, etc. , to achieve the effect of improving work efficiency, avoiding potential safety hazards and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

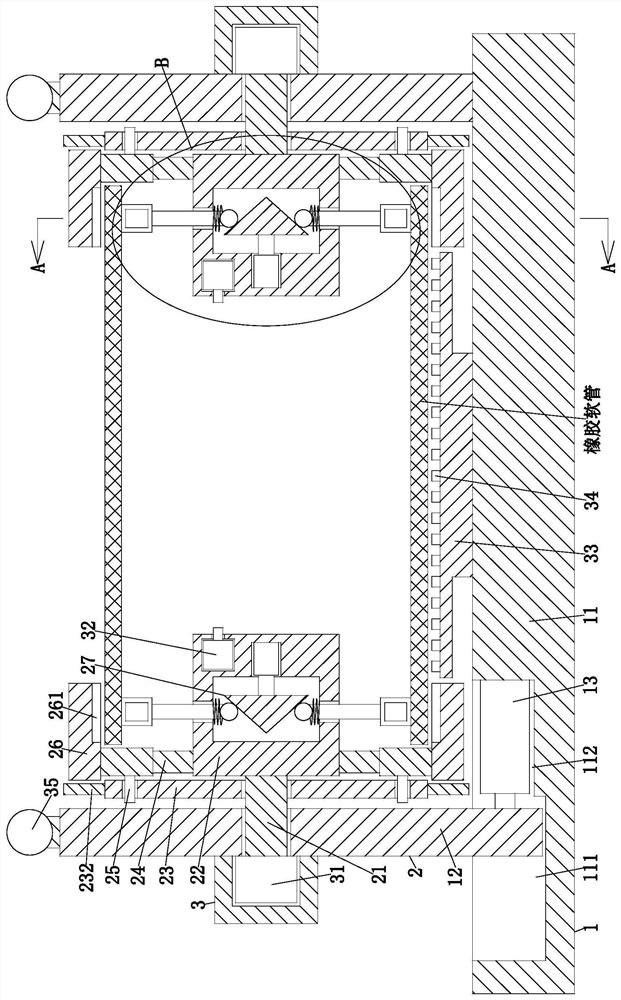

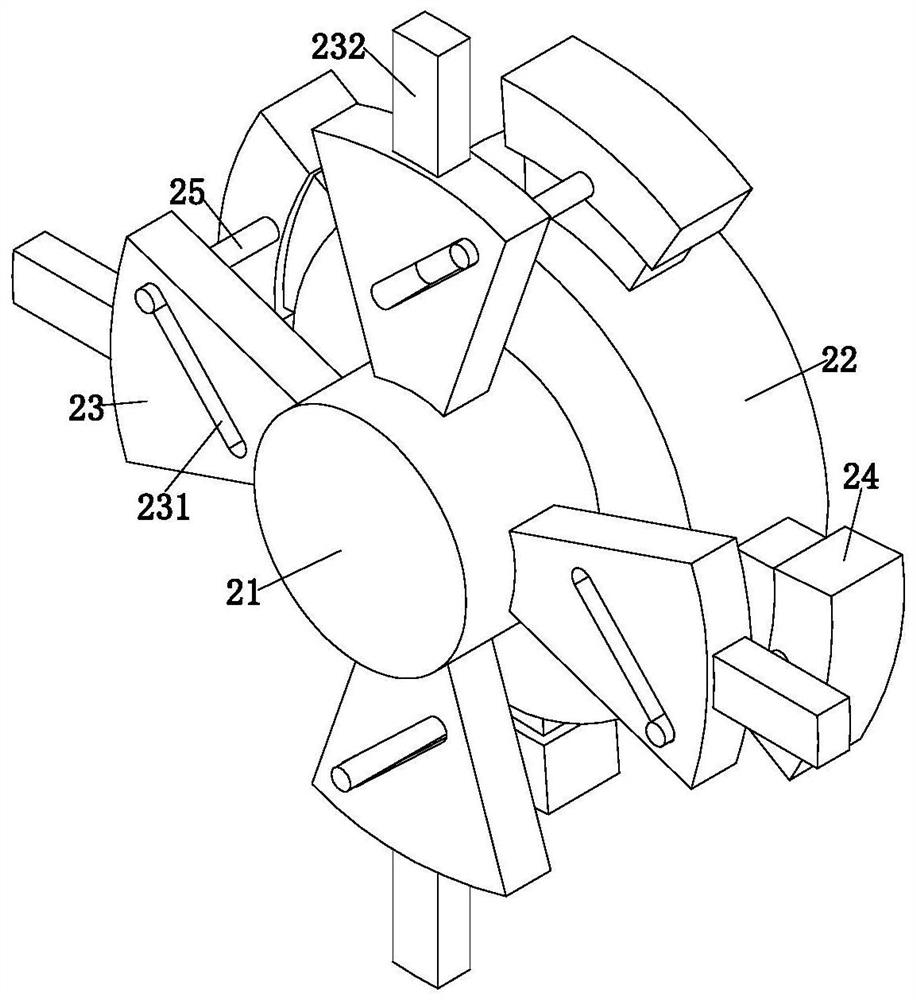

[0031] Such as Figure 1 to Figure 6 As shown, an insulating rubber hose forming detection system includes a frame 1, a clamping unit 2 and a detection unit 3. A linkage groove 111 is opened on the left side of the upper end of the frame 1, and the clamping unit 2 is arranged on the frame 1. On the inner wall, the inner side of the clamping unit 2 is provided with a detection unit 3, wherein:

[0032] The frame 1 includes a base 11, a support plate 12 and a telescopic cylinder 13, wherein: the left side of the upper end of the base 11 is symmetrically provided with a linkage groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com