Adjustable vertical calibration device for inserting type building prefabricated slab

A calibrating device and prefabricated board technology, which is applied in the construction, building structure, processing of building materials, etc., can solve the problems of low measurement accuracy, complicated adjustment, complicated operation, etc., and achieve high positioning accuracy, convenient steering movement and angle. Adjustable, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

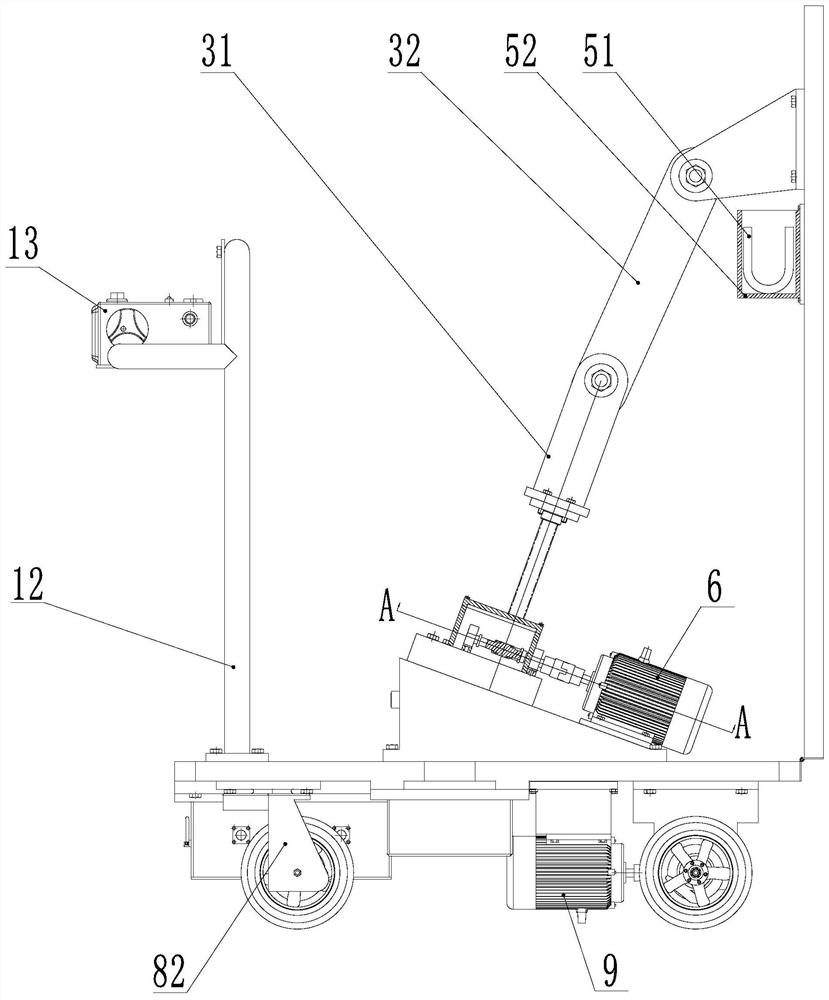

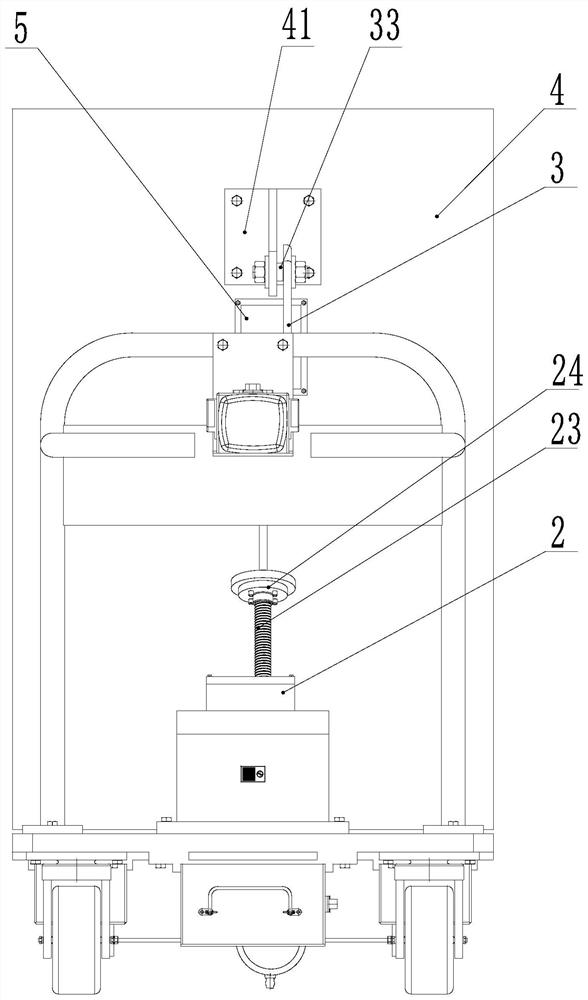

[0029] Such as Figure 1~4 As shown, the embodiment of the present invention provides an adjustable vertical calibration device for plug-in building prefabricated panels, including a flat bottom plate 1, a lifting transmission mechanism, a plane linkage mechanism 3 and a vertical plate 4, and the lifting transmission mechanism is placed obliquely And be installed on the flat bottom plate 1, the inclination angle of lifting transmission mechanism in the present embodiment is preferably 70 degrees, and described plane link mechanism 3 comprises connecting rod one 31 and connecting rod two 32, and the lead screw head of described lifting transmission mechanism The upper flange 24 is fixedly connected with one end of connecting rod one 31 by a bolt, the other end of said connecting rod one 31 is rotatably connected with one end of connecting rod two 32 through a connecting rod shaft 33 and a nut, and the other end of connecting rod two 32 is connected through a connecting rod shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com