A kind of preparation technology of self-caulking anti-seepage curtain type concrete precast pile

A technology of prefabricated concrete piles and preparation process, applied in sheet pile wall, foundation structure engineering, construction, etc., can solve the problems of reduced concrete strength, decreased impermeability, unsatisfactory effect, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

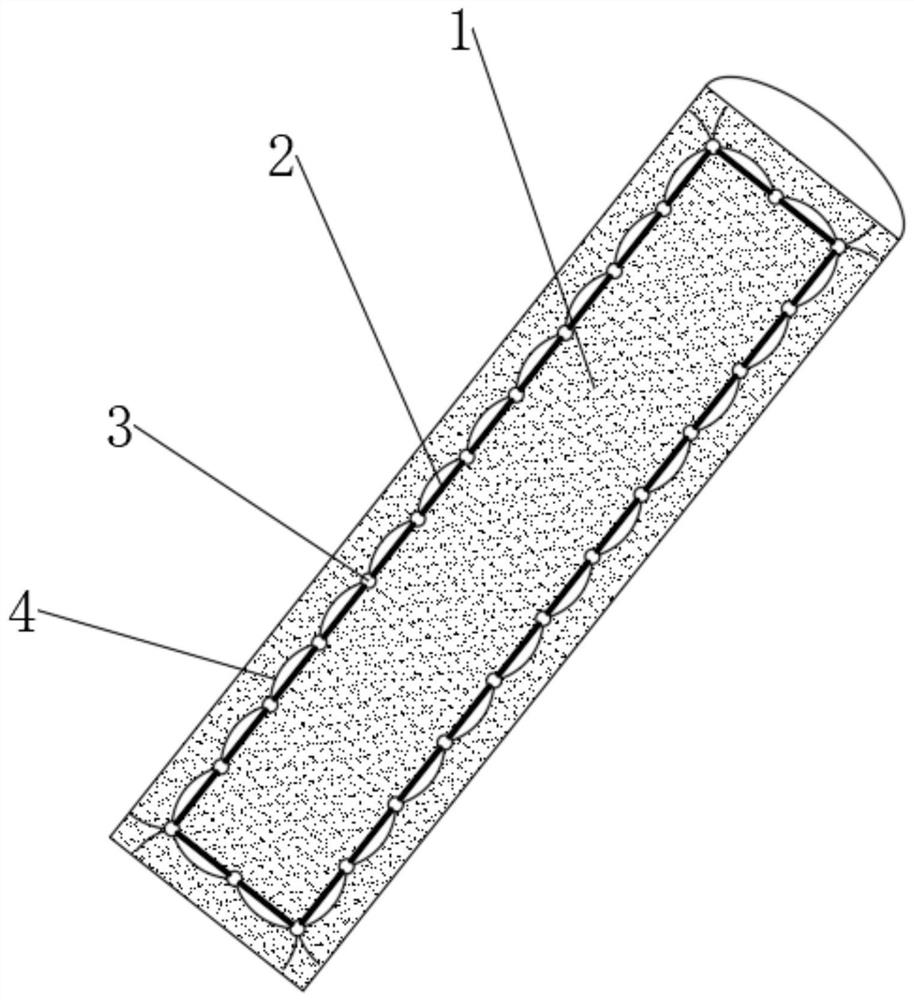

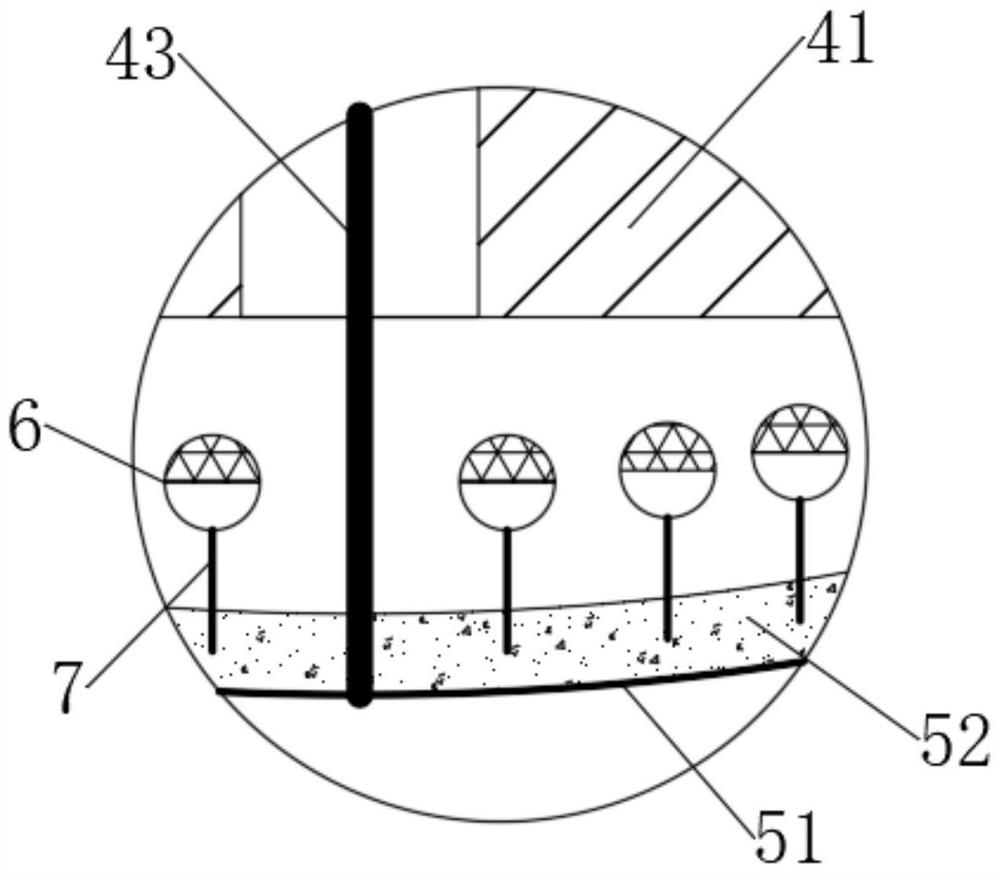

[0045] see figure 1 , a preparation process of self-caulking anti-seepage curtain-type precast concrete pile, comprising the following steps:

[0046] S1. Prepare concrete raw materials and mix them; standby;

[0047] S2. After binding the curtain-type steel cage, put it into the pipe pile mold, and apply a layer of demoulding oil with a thickness of 0.3-0.5mm on the inner wall of the mold;

[0048] S3, pouring the mixed concrete into the pipe pile mold, and centrifugally molding to obtain the prefabricated pile body 1;

[0049] S4. The prefabricated pile body 1 is statically stopped for 2-2.5 hours, and then steamed at atmospheric pressure. The temperature is raised to 75-80°C at 25°C / h, and the constant temperature is 6-8 hours. Patching procedure;

[0050] S5, remove the template and take out the prefabricated pile body 1, carry out natural maintenance, and hoist it to the outer yard.

[0051] The concrete raw material includes the following components in parts by weigh...

Embodiment 2

[0062] see figure 1 , a preparation process of self-caulking anti-seepage curtain-type precast concrete pile, comprising the following steps:

[0063] S1. Prepare concrete raw materials and mix them; standby;

[0064] S2. After binding the curtain-type steel cage, put it into the pipe pile mold, and apply a layer of demoulding oil with a thickness of 0.4mm on the inner wall of the mold;

[0065] S3, pouring the mixed concrete into the pipe pile mold, and centrifugally molding to obtain the prefabricated pile body 1;

[0066] S4. The prefabricated pile body 1 is statically stopped for 2.2 hours, and then steamed at atmospheric pressure, heated to 78°C at 25°C / h, kept at a constant temperature for 7 hours, and then cooled to room temperature within 1 hour, triggering the process of the curtain-type reinforcement cage to be repaired;

[0067] S5, remove the template and take out the prefabricated pile body 1, carry out natural maintenance, and hoist it to the outer yard.

[00...

Embodiment 3

[0071] seefigure 1 , a preparation process of self-caulking anti-seepage curtain-type precast concrete pile, comprising the following steps:

[0072] S1. Prepare concrete raw materials and mix them; standby;

[0073] S2. After binding the curtain-type steel cage, put it into the pipe pile mold, and apply a layer of 0.5mm thick demoulding oil on the inner wall of the mold;

[0074] S3, pouring the mixed concrete into the pipe pile mould, centrifugal forming, to obtain the prefabricated pile body 1;

[0075] S4. The prefabricated pile body 1 is statically stopped for 2.5 hours and then steamed at atmospheric pressure, heated to 80°C at 25°C / h, kept at a constant temperature for 8h, and then cooled to room temperature within 1h, triggering the process of the curtain-type reinforcement cage to be repaired;

[0076] S5. Remove the formwork, take out the prefabricated pile body 1, carry out natural maintenance, and hoist it to the outer yard.

[0077] The concrete raw material inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com