Yarn cleaning device

A technology for cleaning device and yarn, which is applied to fiber cleaning, equipment configuration for processing textile materials, and liquid/gas/vapor removal by suction method, which can solve the problems of inability to filter and discharge waste, lack of yarn draining and cleaning, etc. Achieve the effect of increasing convenience, facilitating recycling and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

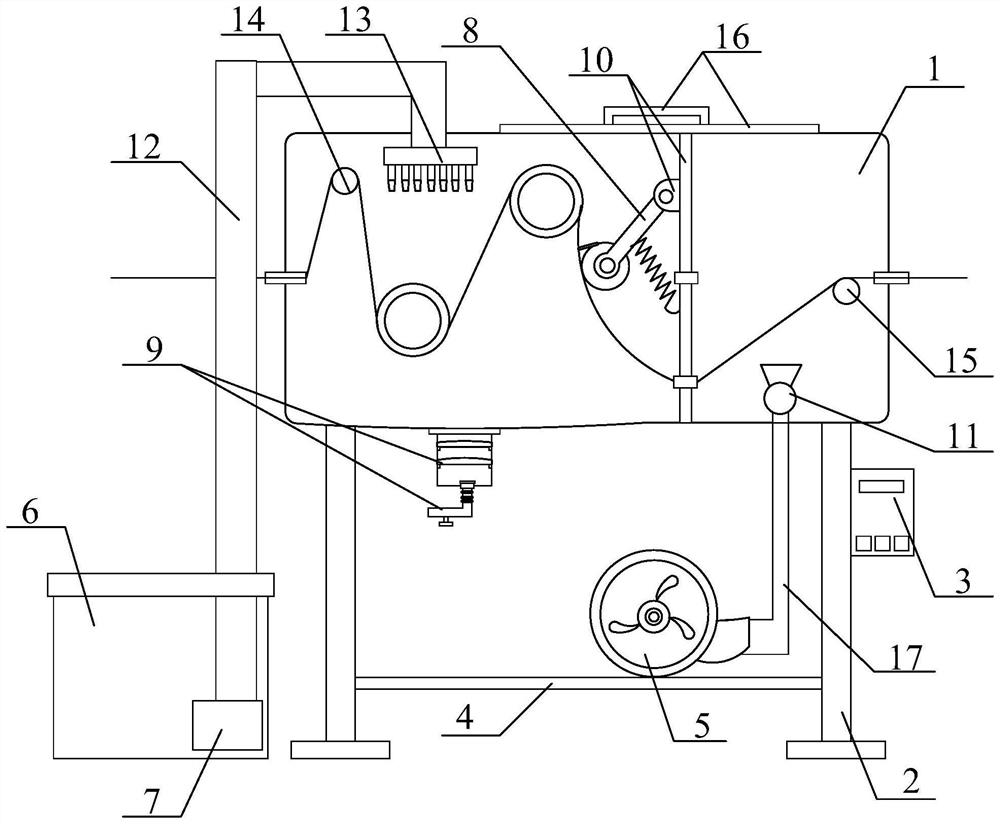

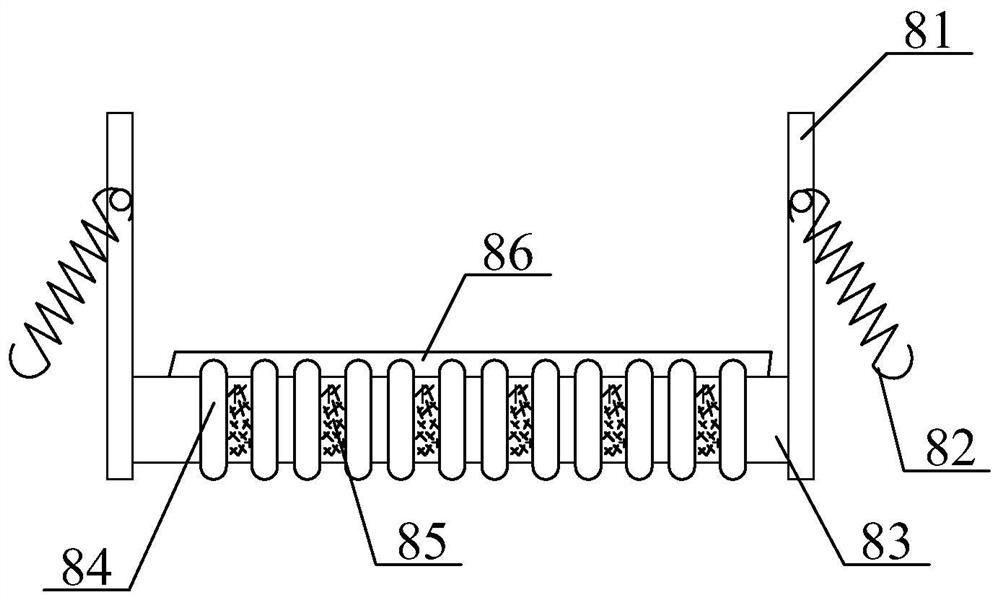

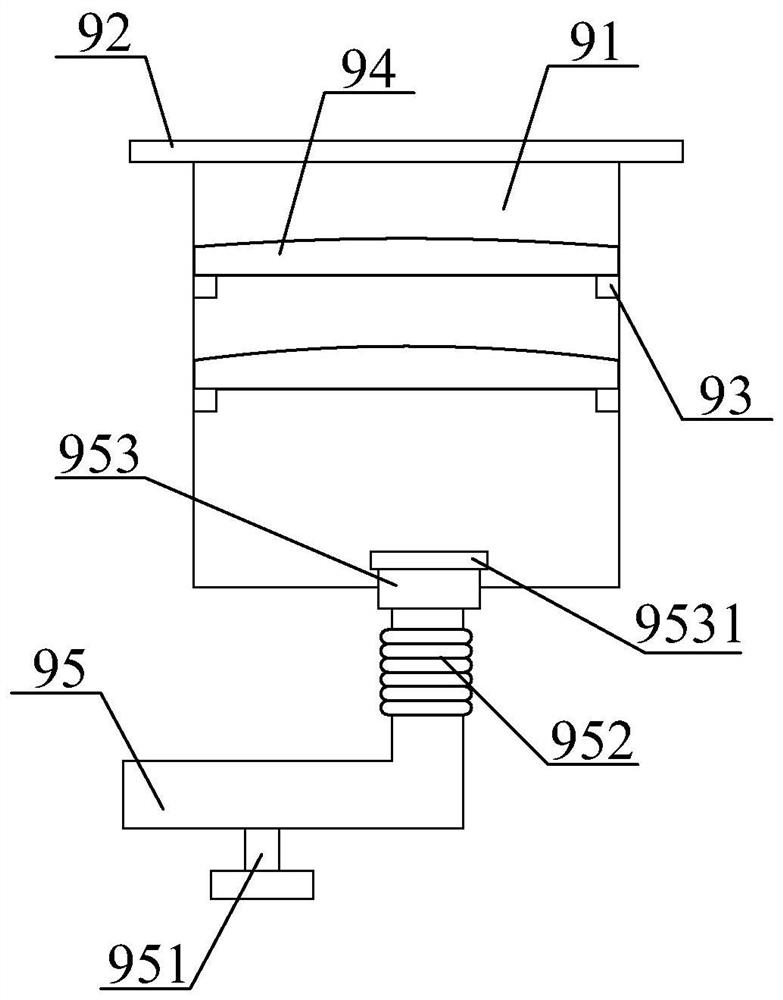

[0039] as attached figure 1 As shown, the present invention provides a yarn cleaning device, including a cleaning treatment box 1, a support column 2, a control box 3, a support horizontal plate 4, a hot air blower 5, a water storage tank 6, a submersible pump 7, and a yarn draining cleaning rack 8 , convenient cleaning and filtering floor drain assembly 9, yarn wire restraint plate assembly 10, drying pipe 11, water guide pipe 12, cleaning spray plate 13, first guide rod 14, second guide rod 15, manhole door 16, air guide pipe 17 , the bobbin row 18, the bobbin row 19, the first guide roller 20, the second guide roller 21 and the yarn main body 22, and the support columns 2 are bolted to the bottom four corners of the cleaning treatment box 1; The control box 3 is screw-connected to the right upper part of the support column 2 provided on the right front; the horizontal support plate 4 horizontal screw is connected to the inner lower part of the support column 2; the hot air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com