Medical glass bottle with low liquid medicine residue and preparation method thereof

A glass bottle and medicine technology, applied in the coating and other directions, can solve the problems of aggravating the corrosion of pharmaceutical packaging materials, increasing the product cost, and the waste of medicines, so as to reduce the phenomenon of hanging on the wall, increase the contact angle of water droplets, and reduce the effect of migration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment provides a medical glass bottle with low liquid residue and low liquid residue, the preparation steps of which include:

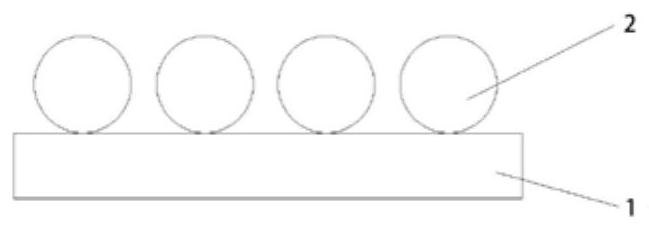

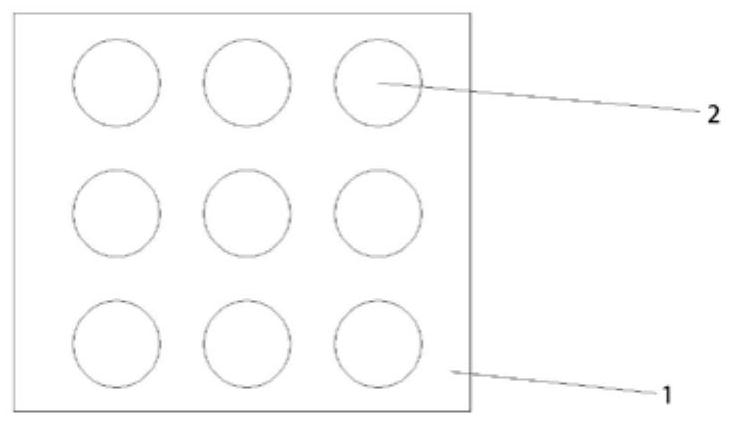

[0035] S1, adding polystyrene microspheres and dispersant to ethanol to make a 0.2wt% polystyrene microsphere solution; filling the 0.2wt% polystyrene microsphere solution in a medical glass bottle, After standing still for 15min, the 0.2wt% polystyrene microsphere solution was poured out in a medical glass bottle, and the medical glass bottle was heated at 100°C for 15min, as figure 1 and figure 2 As shown, to coat polystyrene microspheres 2 on the inner surface 1 of the medical glass bottle;

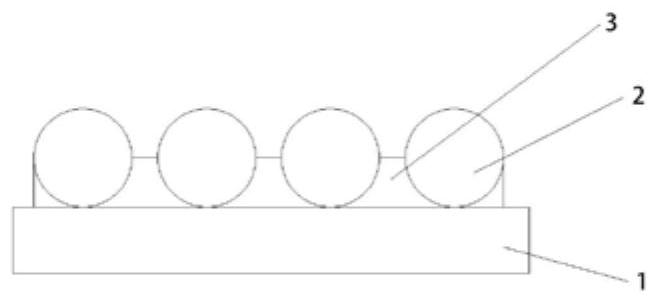

[0036] S2, adding organopolysiloxane and dispersant to deionized water to make a 15wt% polysiloxane dispersion solution; filling the 15wt% polysiloxane dispersion solution in a medical glass bottle, statically After standing for 15min, pour out the polysiloxane dispersion solution in a medical glass bottle, such as image 3 As shown, to in...

Embodiment 2

[0039] This embodiment provides a medical glass bottle with low liquid residue, the preparation steps of which include:

[0040] S1, adding polystyrene microspheres and dispersant to ethanol to make a 0.1wt% polystyrene microsphere solution; filling the 0.1wt% polystyrene microsphere solution in a medical glass bottle, After standing still for 20min, pour out the 0.1wt% polystyrene microsphere solution in the medical glass bottle, and heat the medical glass bottle at 150°C for 10min, as figure 1 and figure 2 As shown, to coat polystyrene microspheres 2 on the inner surface 1 of the medical glass bottle;

[0041] S2, adding organopolysiloxane and dispersant to deionized water to make a 20wt% polysiloxane dispersion solution; filling the 20wt% polysiloxane dispersion solution in a medical glass bottle, static After standing for 10min, pour out the polysiloxane dispersion solution in a medical glass bottle, such as image 3 As shown, to infiltrate the polysiloxane into the ga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com