Pretreatment process and device for preparing touch screen by taking film material as substrate

A pretreatment device and pretreatment technology, applied in the direction of lamination device, adhesive type, lamination, etc., can solve the problems of difficult glue and film edge alignment, low efficiency, water absorption and degumming, etc., to avoid wrinkling Problems and scratches, reduce manual operations, improve yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The pretreatment process of preparing the touch screen with the film material as the base, the specific pretreatment is to bond the base film and the glass carrier with self-adhesive, including the following steps:

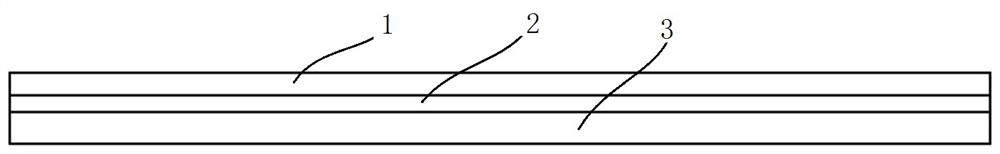

[0034] 1) The base film is the raw material of the capacitive screen film, including the bottom PET film, which is also provided with a passivation layer, an eradication layer and an ITO layer. The front protective film is set above the ITO layer, and the lower layer of the PET film is a back protective film. The front protective film is a 30μm PP film, and the thickness of the base film is 50μm. First replace the front protective film of the base film with a PET protective film using a film laminating machine. The thickness of the PET protective film is 125 μm; the speed of the film is 1.5m / min, and the pressure is 1 kg / cm 2 , at this time, the film is a normal temperature film;

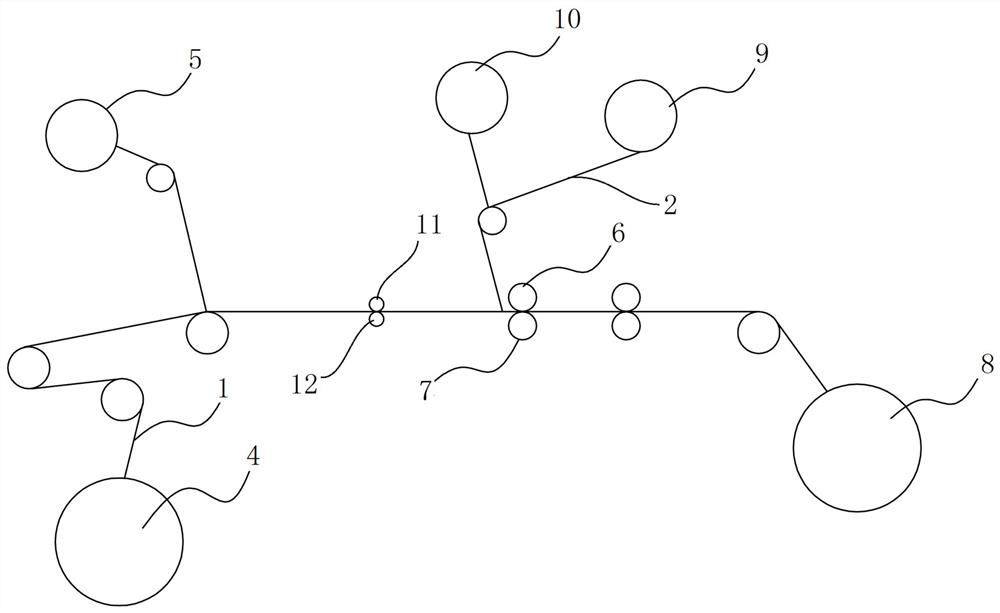

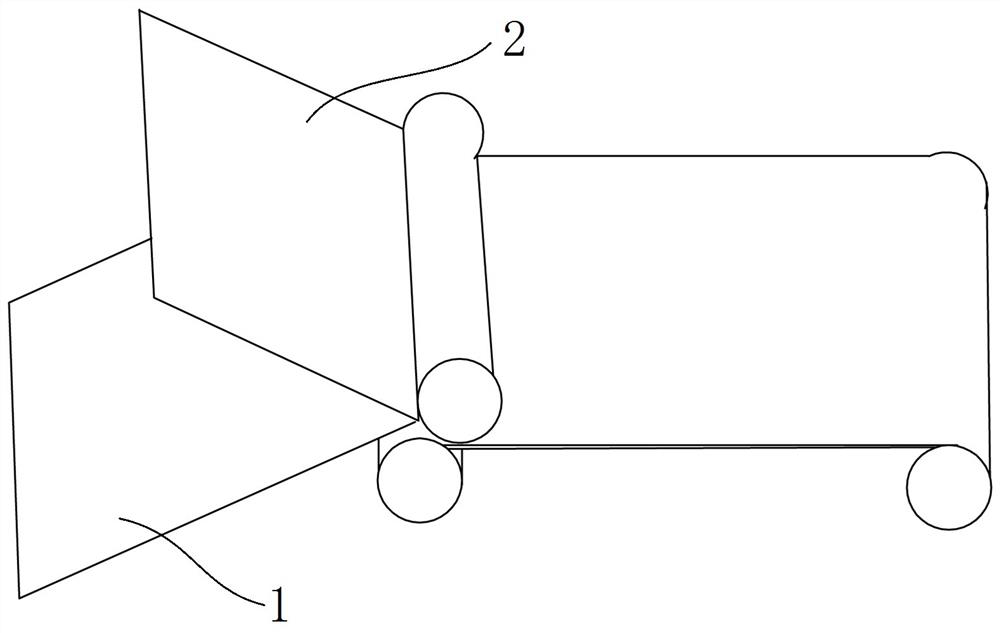

[0035] 2) Paste the self-adhesive and base film using roll-to-roll laminati...

Embodiment 2

[0041] The pretreatment process of preparing the touch screen with the film material as the base, the specific pretreatment is to bond the base film and the glass carrier with self-adhesive, including the following steps:

[0042] 1) The base film is the raw material of the capacitive screen film, including the COP film at the bottom, on which there are also a passivation layer, an eradication layer and an ITO layer, a front protective film is set above the ITO layer, and the lower layer of the COP film is a back protective film, among which The front protective film is a 30μm PP film, and the thickness of the base film is 100μm. First replace the front protective film of the base film with a PET protective film using a film laminating machine. The thickness of the PET protective film is 125 μm; the speed of the film is 2m / min, and the pressure is 1.5 kg / cm 2 , at this time, the film is a normal temperature film;

[0043] 2) Paste the self-adhesive and base film using roll-to...

Embodiment 3

[0048] The pretreatment process of preparing the touch screen with the film material as the base, the specific pretreatment is to bond the base film and the glass carrier with self-adhesive, including the following steps:

[0049] 1) The base film is the raw material of the capacitive screen film, including the bottom PET film, on which there are passivation layer, shadow removal layer and ITO layer, the front protective film is set above the ITO layer, and the lower layer of the COP film is the back protective film. The front protective film is a 30μm PP film, and the thickness of the base film is 100μm. First replace the front protective film of the base film with a PET protective film using a film laminating machine. The thickness of the PET protective film is 125 μm; the speed of the film is 2m / min, and the pressure is 1kg / cm 2 , at this time, the film is a normal temperature film;

[0050] 2) Paste the self-adhesive and base film using roll-to-roll laminating equipment. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com