Aluminum alloy processing equipment and its film sticking mechanism

A film sticking mechanism, aluminum alloy technology, applied in other manufacturing equipment/tools, manufacturing tools, chemical instruments and methods, etc., can solve the problems of occupation, slow film sticking efficiency, and nowhere to store aluminum alloy products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the above-mentioned objects, features and advantages of the present invention more obvious and understandable, the specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings. In the following description, many specific details are explained in order to fully understand the present invention.

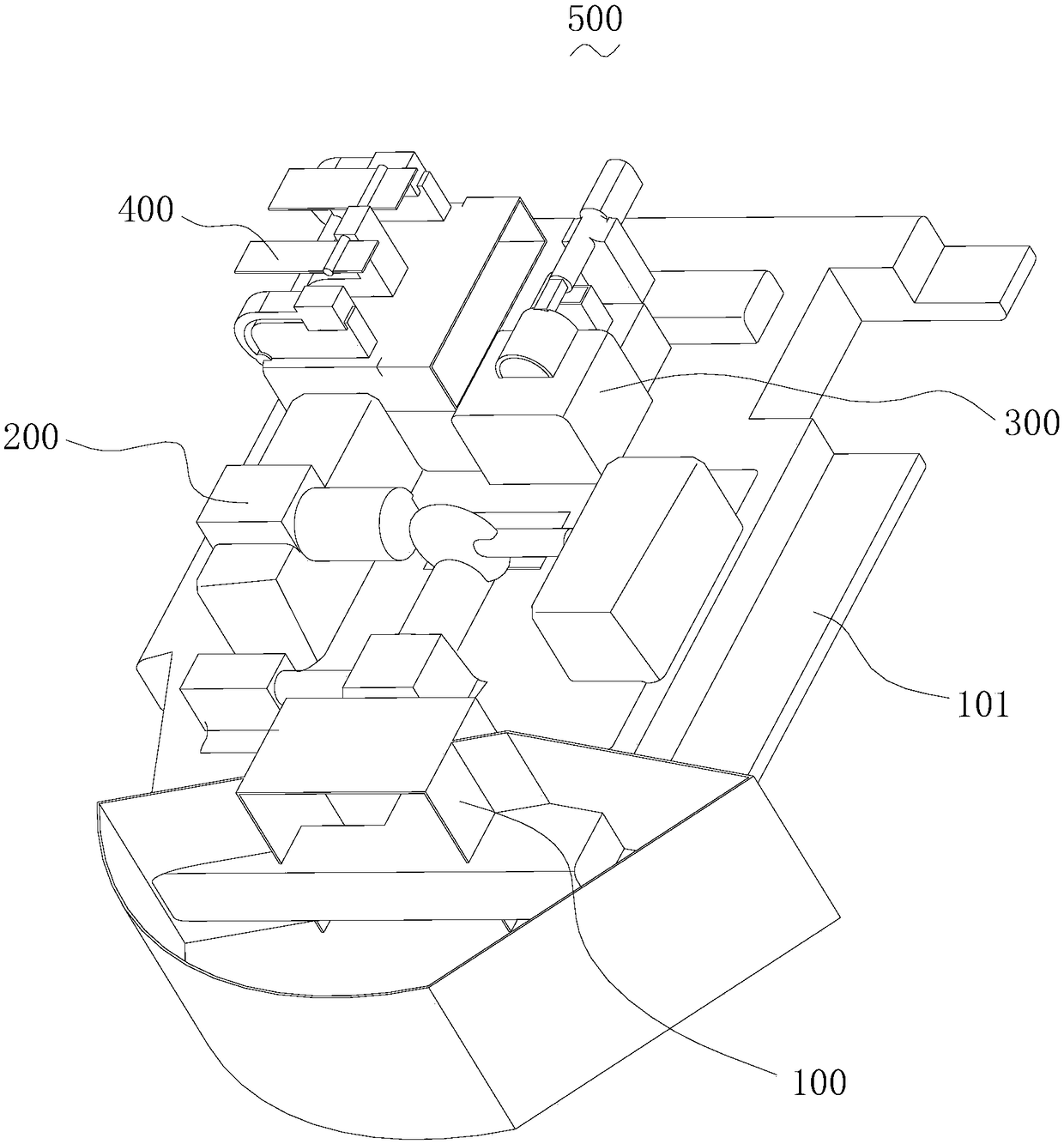

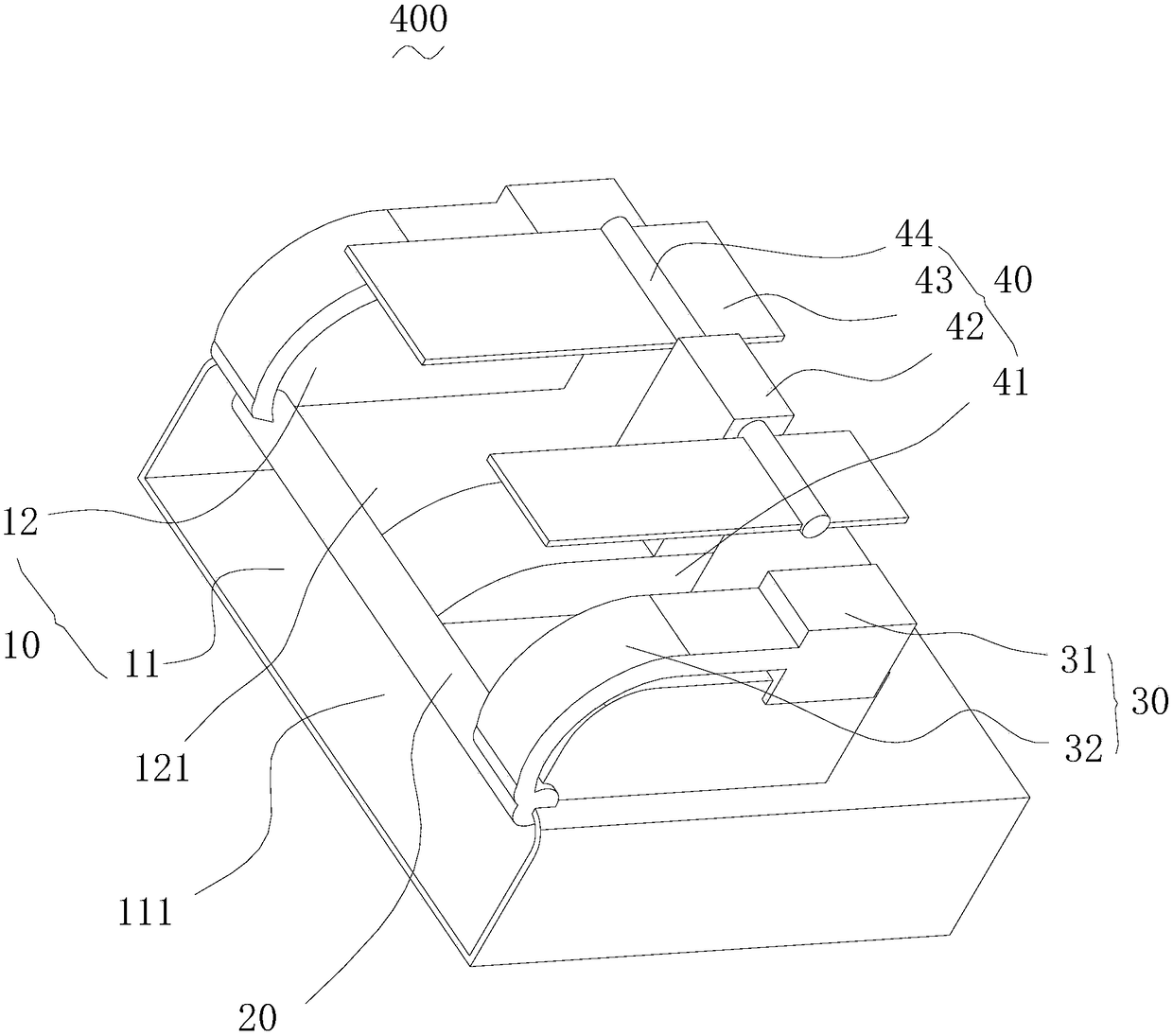

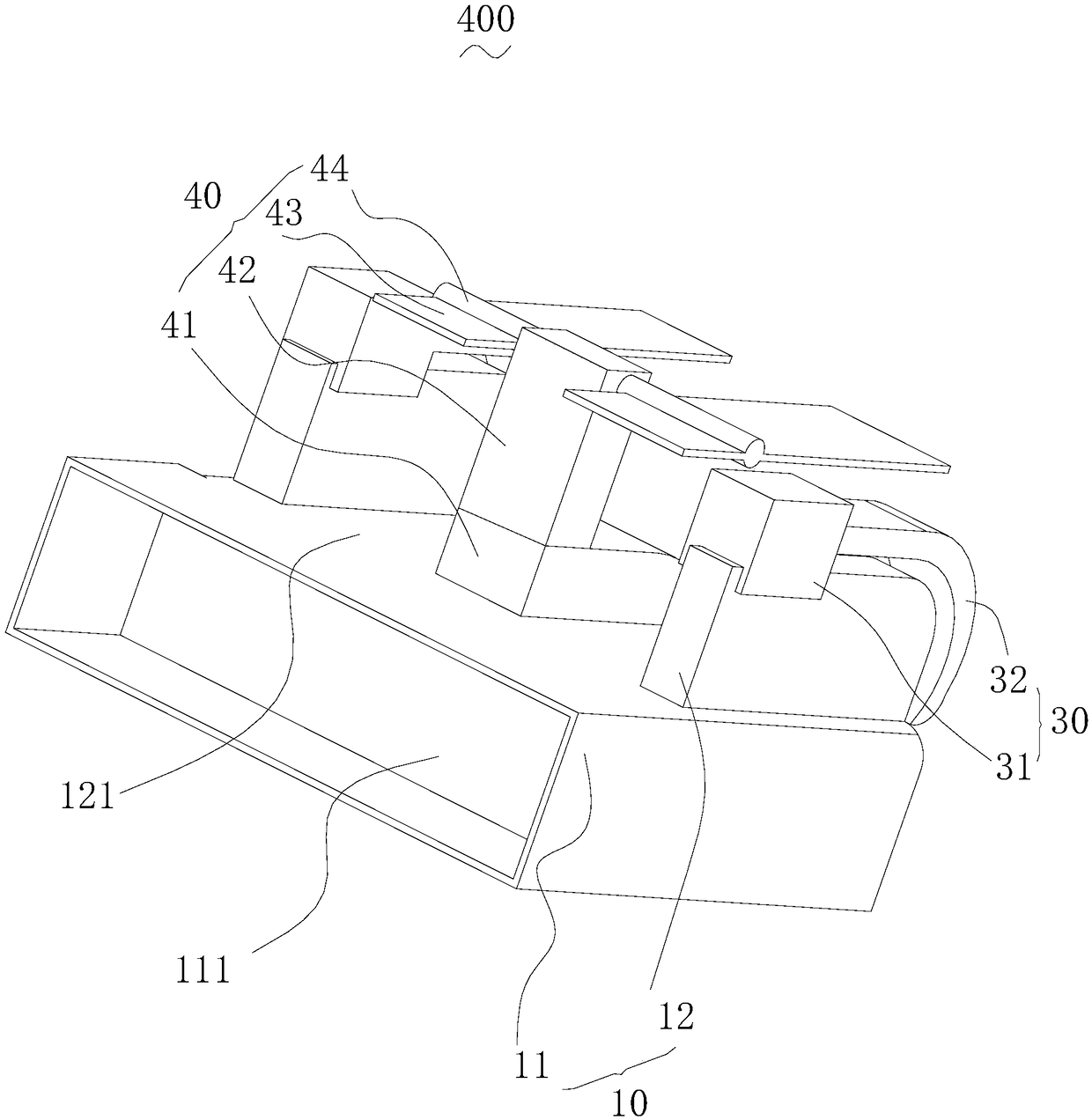

[0020] The invention relates to an aluminum alloy film sticking mechanism. The aluminum alloy film sticking mechanism includes a storage component, a film roll, a holding component and a film sticking component. For example, the storage assembly includes a storage box and two installation blocks, and a storage space is opened in the storage box, and the two installation blocks are respectively arranged on opposite sides of the storage box; the film roll is arranged in the storage box. Between the two mounting blocks. For example, the pulling assembly includes two winding pieces and two pulling strips,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com