A data-driven digital laying hen breeding system

A data-driven, breeding system technology, applied in the field of breeding systems, can solve the problems of high risks, losses, hidden dangers of breeding systems, and achieve the effects of high breeding quality, high breeding efficiency, and guaranteeing quality and efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

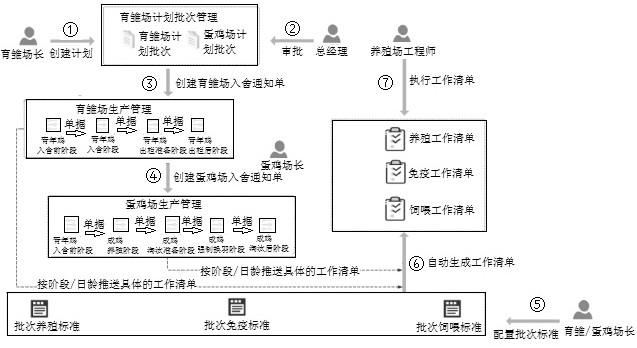

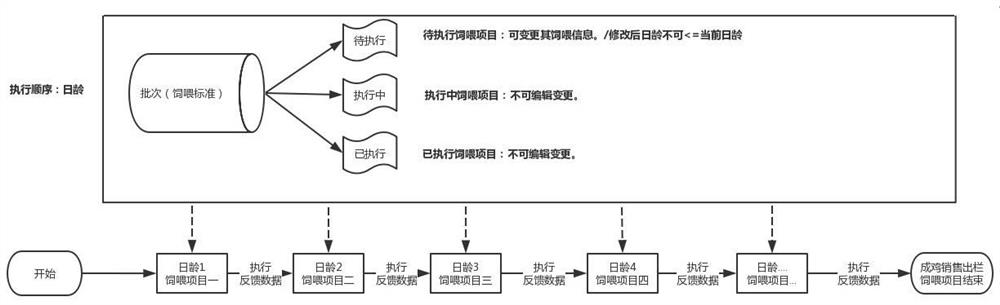

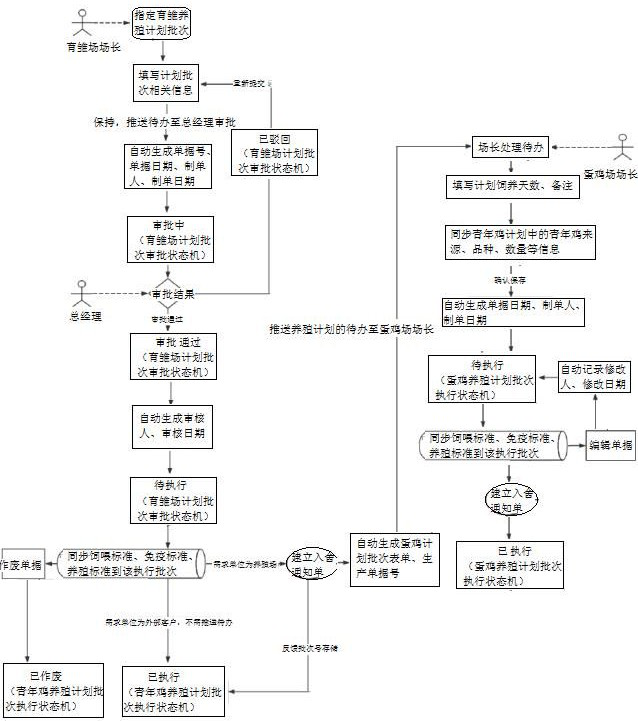

[0049] A data-driven digital layer breeding system, such as Image 6 As shown, it includes a laying hen breeding basic data module, a brooding production management module, and a laying hen production management module, and the laying hen breeding basic data module includes a breeding standard unit, a feeding standard unit, an immunization standard unit, and an equipment operation and maintenance standard unit; The brooding production management module and the laying hen production management module respectively include a brooding plan batch management unit and a laying hen plan batch management unit; the brooding farm manager creates a brooding farm planned batch through the brooding plan batch management unit and sends it to the general manager. The manager approves and approves. After approval, the corresponding feeding standards, immunization standards, and breeding standards are synchronized to the brooding plan batches, and the layer batch plan is automatically generated a...

Embodiment 2

[0053] This embodiment is optimized on the basis of Embodiment 1, such as figure 1 As shown in the figure, the batch management unit of the brooding plan sequentially generates notification documents to the brooding farm manager according to the stage before the chicks are put into the house, the breeding stage of the young chickens, the preparation stage of the young chickens, and the stage after the young chickens are released.

[0054] Further, in the stage before the chicks are put into the house, push the chick placement notice to the brooding farm manager for confirmation. If the brooding farm manager confirms the placement, it is necessary to fill in the actual placement time, the estimated price, and the estimated gift amount. After getting the brooding order, the system will regularly push the brooding order to the brooding farm manager; if the brooding farm manager changes the brooding, you need to fill in and modify the planned arranging time.

[0055] Further, the...

Embodiment 3

[0059] This embodiment is optimized on the basis of Embodiment 1 or 2, such as figure 1 As shown, the laying hen planning batch management unit sequentially generates notification documents to the laying hens according to the stage before the young chickens are put into the house, the adult chicken breeding stage, the adult chicken elimination preparation stage, the adult chicken forced moulting stage, and the adult chicken elimination stage. Field length.

[0060] Further, before the chicks are put into the house, the brooding planning batch management unit establishes the planning batch placement notice, and automatically generates the laying hen planning batch form and pushes it to the laying hen planning batch management unit to generate the laying hen breeding batch. The second plan is sent to the laying hen farm manager; the laying hen farm manager fills in the planned feeding days, and synchronizes the source, breed, and quantity information of the young chickens in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com