Load switch

A technology of load switches and components, applied in the direction of electric switches, power devices inside switches, electrical components, etc., can solve problems such as long operating time, contact vibration, burning, etc., and achieve the effect of high intelligence and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

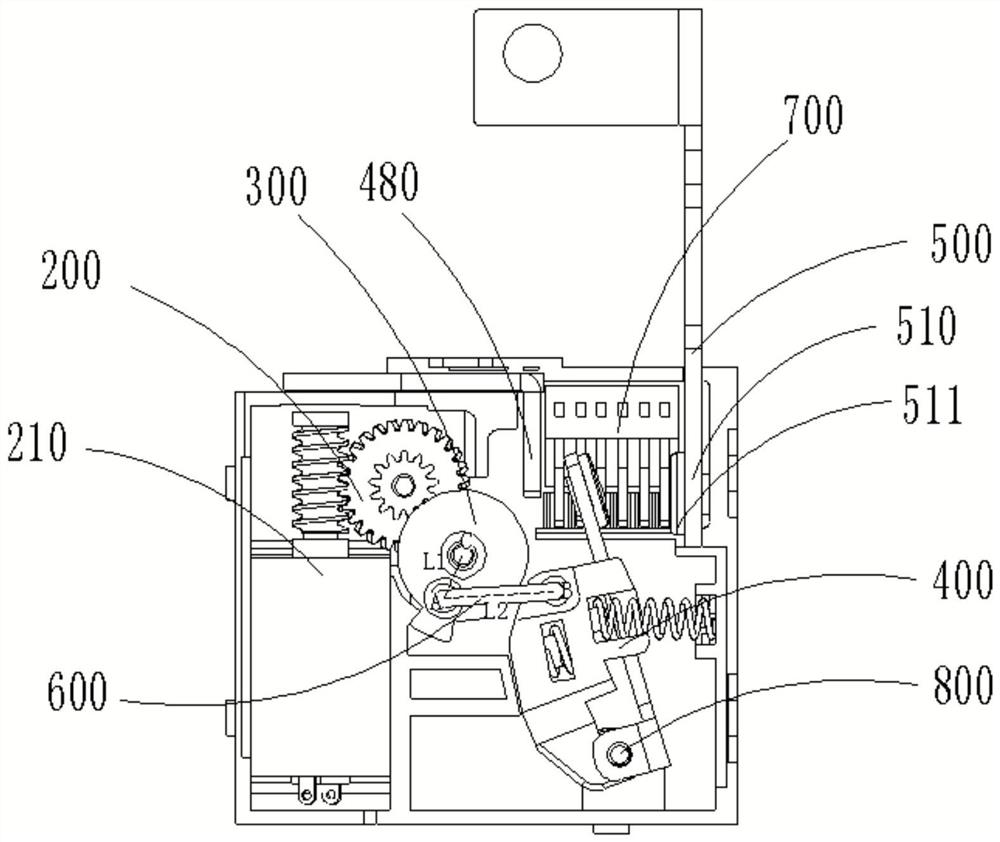

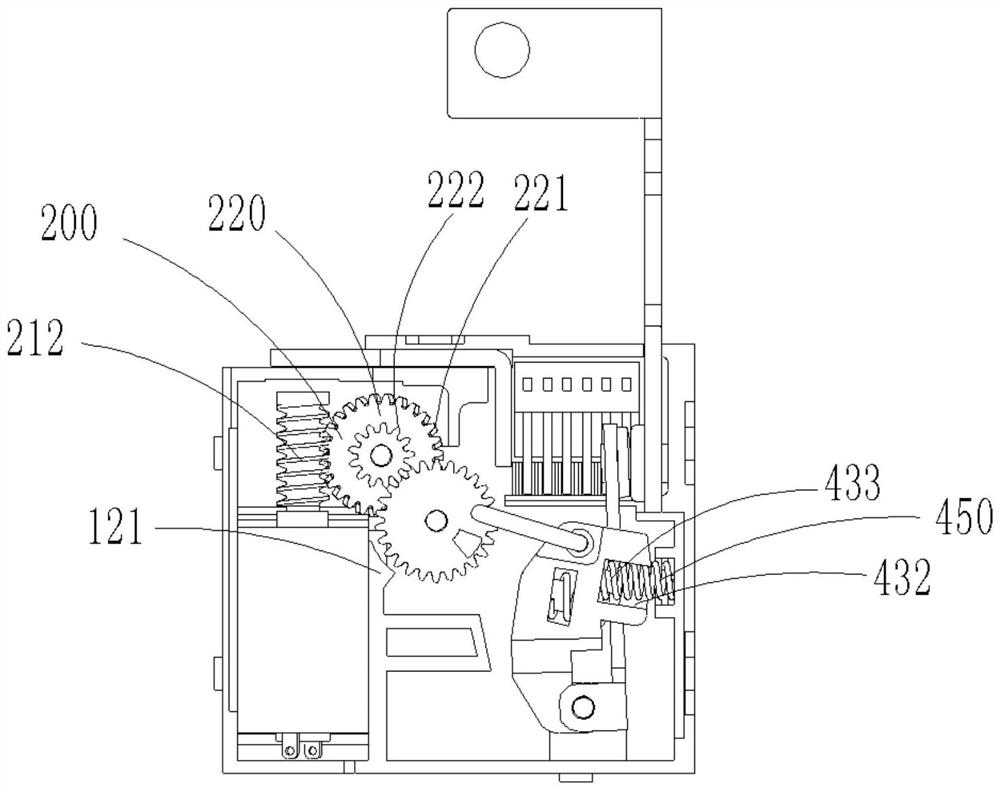

[0044] Such as Figure 1 to Figure 10 As shown, this embodiment discloses a load switch, the load switch includes a motor-driven reduction gear assembly 200, a moving contact assembly 400, and an operation that is rotationally connected to the motor-driven reduction gear assembly 200 and the moving contact assembly 400 respectively. Assembly 300 , static contact assembly 500 , at least one connecting rod 600 connecting the operating assembly 300 and the moving contact assembly 400 , and an arc extinguishing device 700 .

[0045] Wherein, the moving contact assembly 400 can rotate around the shaft 800, when the motor drives the reduction gear assembly 200 to drive the moving contact assembly 400 to rotate through the operating assembly 300 and the connecting rod 600, the The movable contact 420 on the movable contact assembly 400 is connected or disconnected from the static contact assembly 500, respectively as figure 2 and figure 1 shown.

[0046] The load switch of the pr...

no. 2 example

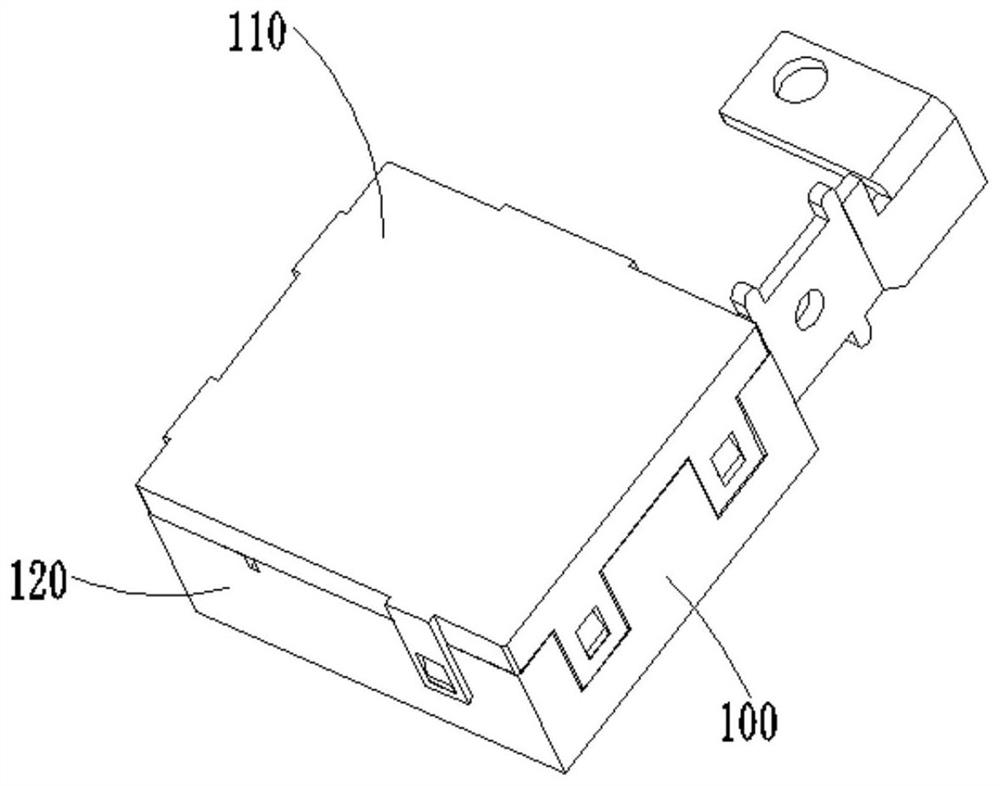

[0065] In this embodiment, the load switch can also be realized in other ways, such as Figure 9 and Figure 10 shown. In this embodiment, the shaft 800 passes through the moving contact rod 410, and the two ends of the shaft 800 are respectively fixed on the upper cover 110 and the lower cover 120 of the insulating housing 100, the moving contact The head rod 410 can rotate around the shaft 800, and the two ends of the connecting rod 600 are respectively movably connected with the operation assembly 300 and the contact support 430. When the operation assembly 300 is in the motor reduction gear assembly 200 When rotating under the drive of the connecting rod 600, the contact support 430 can translate relative to the insulating shell 100, and a sliding groove 436 is provided at the bottom of the contact support 430, and the insulating shell 100 is provided with a positioning block or slide rail matched with the sliding groove 436, and the contact support 430 can translate alo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com