Intelligent forming workshop for multi-specification marine pipes and control method

A multi-specification, pipe technology, applied in the field of pipe processing, can solve the problems of lack of data collection and effective information management system, lack of intelligent scheduling methods in pipe processing workshops, lack of workshop fault monitoring systems and processing methods in marine pipe forming workshops, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

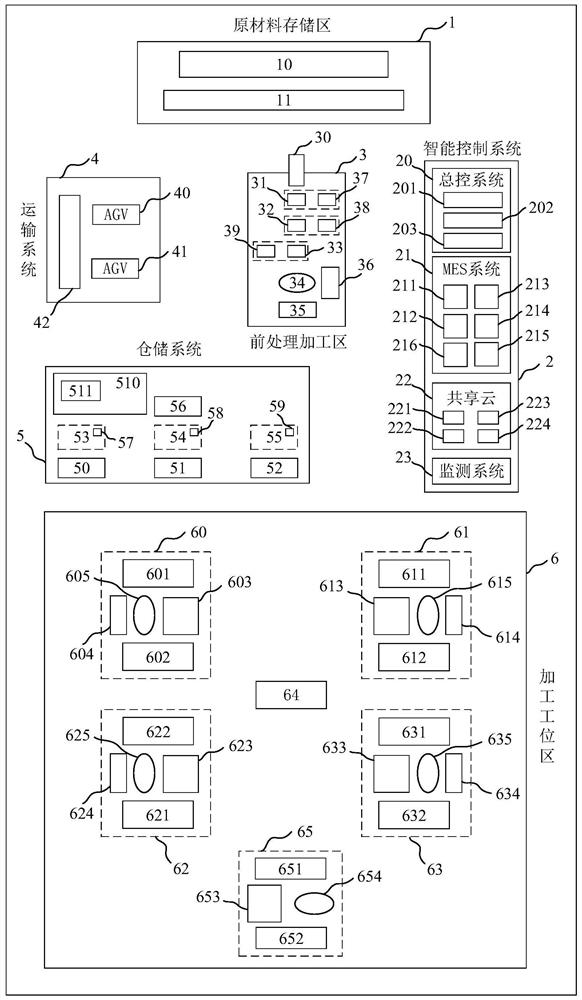

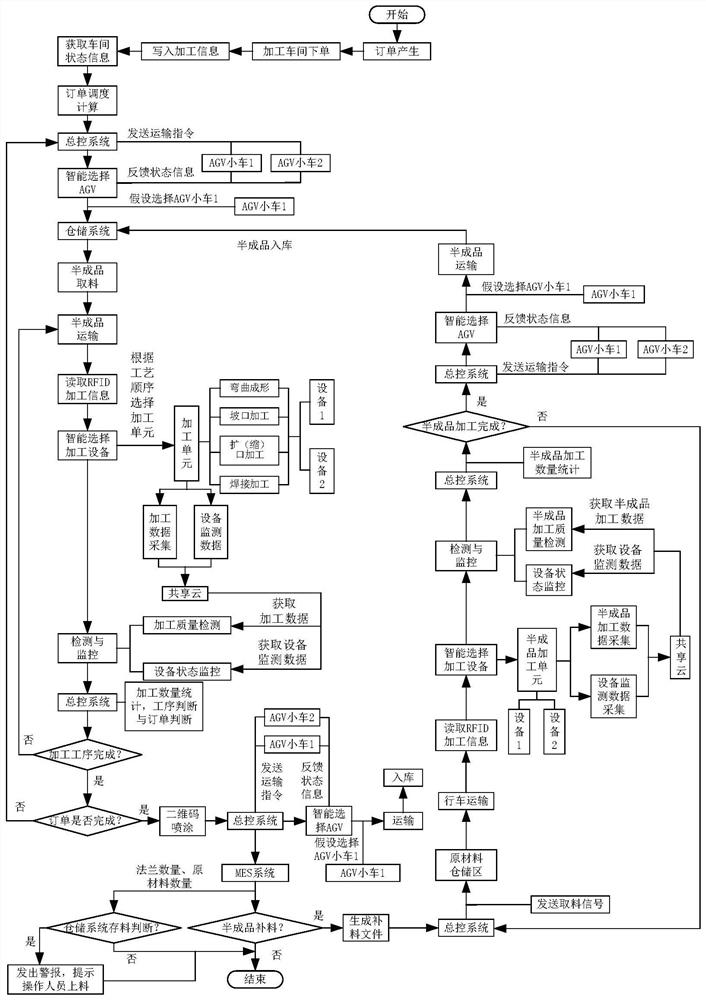

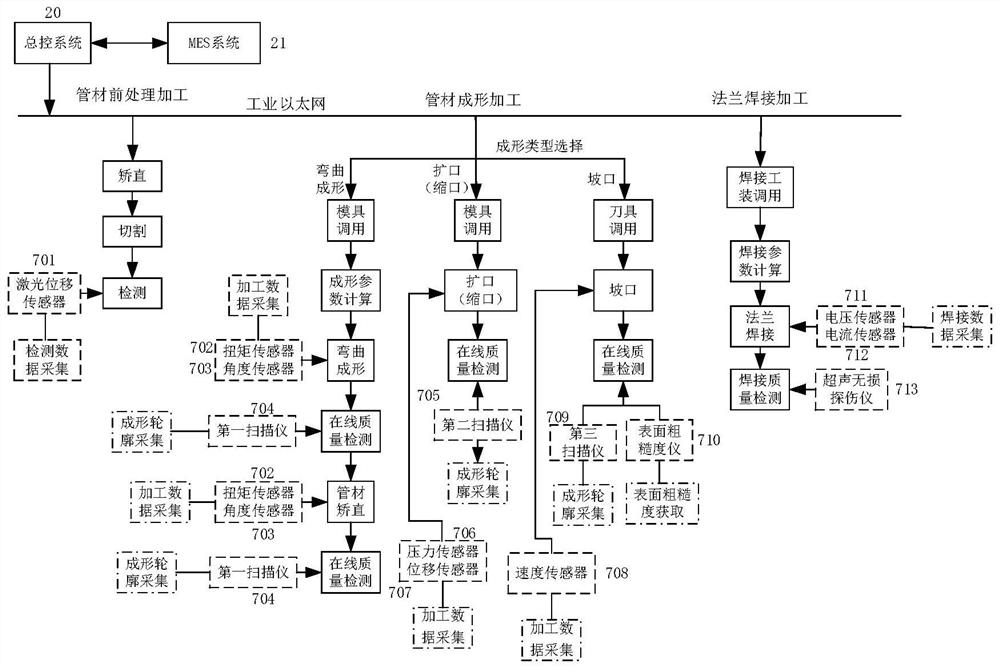

[0105] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0106] In the existing technology, there are several problems as pointed out in the background technology about the marine pipe forming workshop, such as not being suitable for the marine pipe forming workshop with many types of pipes and various forming processes, it takes a lot of time to find the cause of the failure, and the lack of In order to overcome the above problems in the collection of relevant data in the processing process and the effective management of information, this application proposes an intelligent forming workshop for multi-specification marine pipes.

[0107] figure 1 As shown, it is the specific structure of a multi-specification mari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com