Point heat source solid material thermophysical parameter testing experimental device

A technology of thermophysical parameters and solid materials, which is applied in the field of experimental devices for measuring thermophysical parameters of solid materials with point heat sources, can solve problems such as surface area calculation errors, higher requirements for the surface flatness of test pieces, and the influence of laser heating power conversion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0019] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

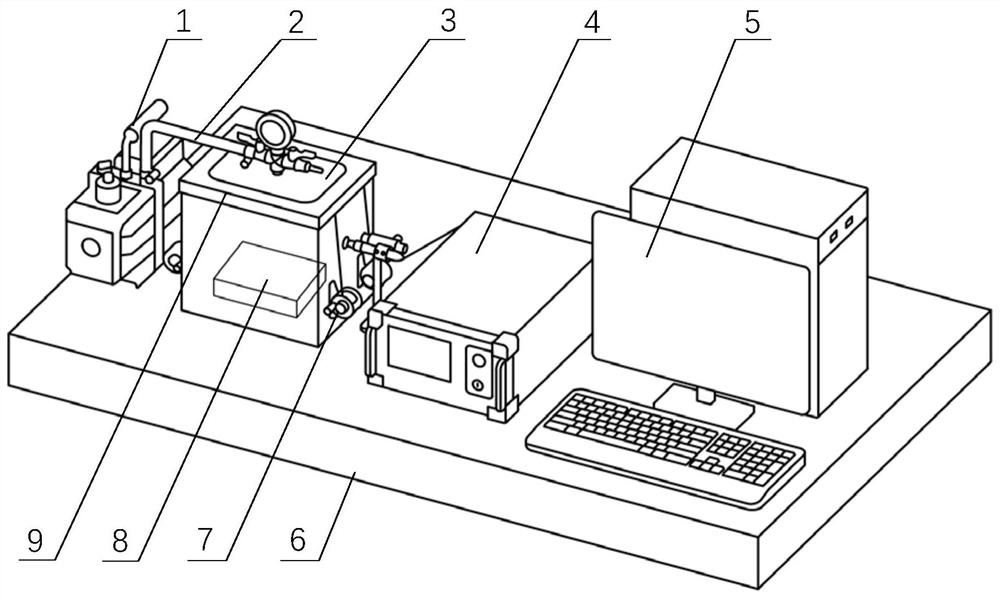

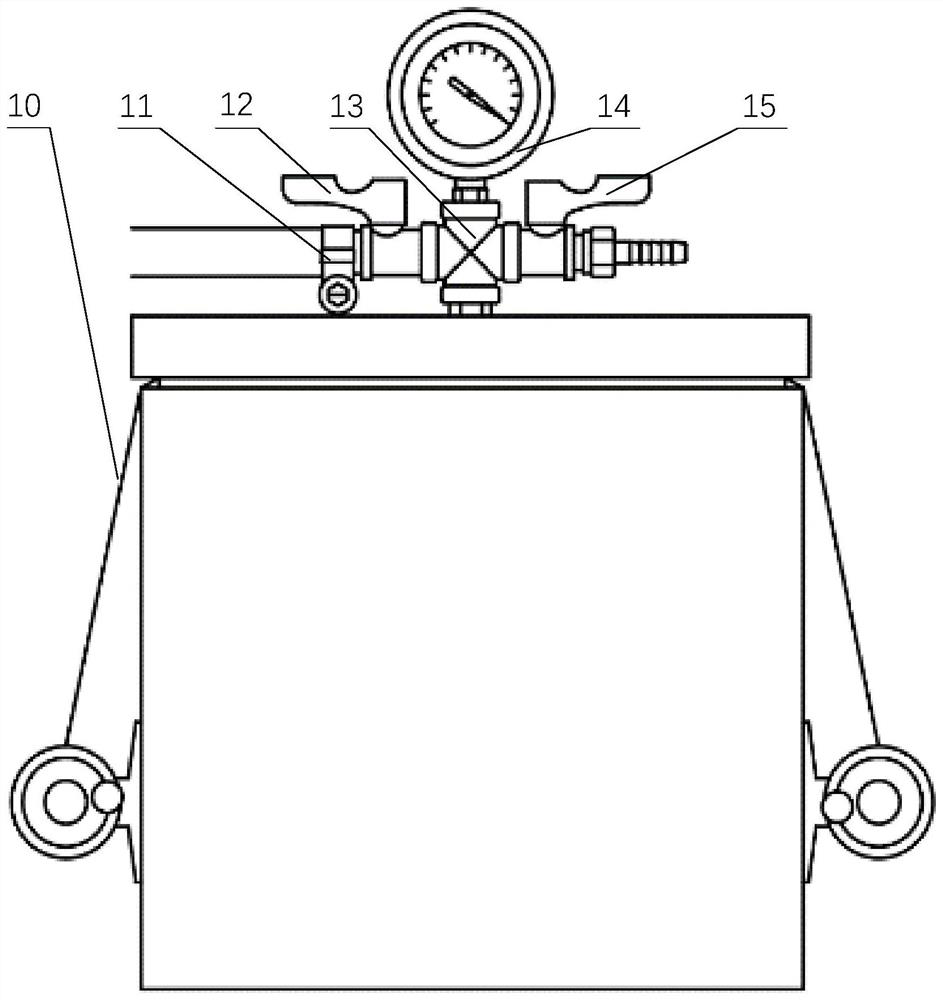

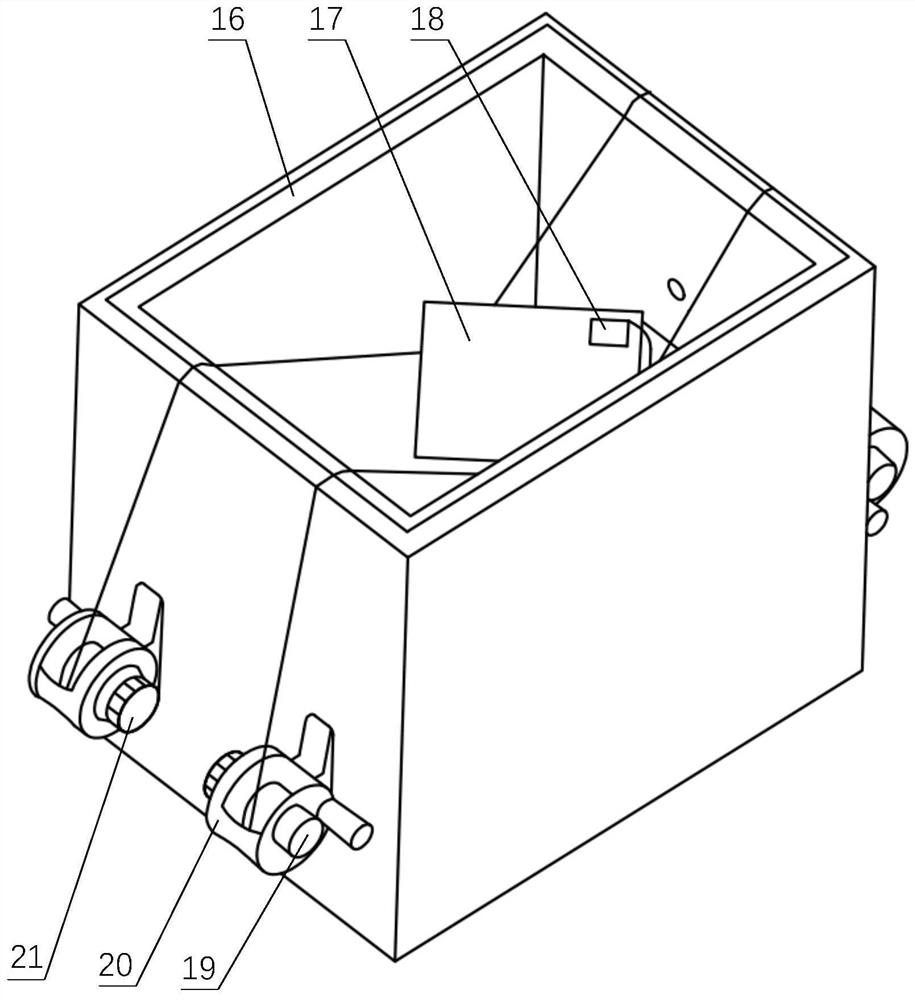

[0020] refer to figure 2 , the vacuum pump 1 is installed on the operating table 6, which creates a vacuum environment and reduces the influence of the external environment on the experimental temperature during the experiment, thereby improving the test accuracy. At the beginning of the experiment, turn on the vacuum pump 1. The vacuum pump 1 will evacuate the vacuum box through the PVC pipe 2 connected to the suction port of the vacuum pump 1 by the clamp 11. The cross four-way valve 13 is installed in the center of the upper end cover 3 by screws. 3 is surrounded by a rubber sleeve 9; the right end port of the exhaust valve 12 is connected to the left end port of the cross four-way valve 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com