Multi-dimensional vibration simulation device based on structural coupling

A simulation device and multi-dimensional technology, applied in the field of multi-dimensional vibration simulation device based on structural coupling, can solve the problems of increasing time cost and rare equipment literature reports, and achieve the effect of reducing coupling vibration and avoiding coupling vibration damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

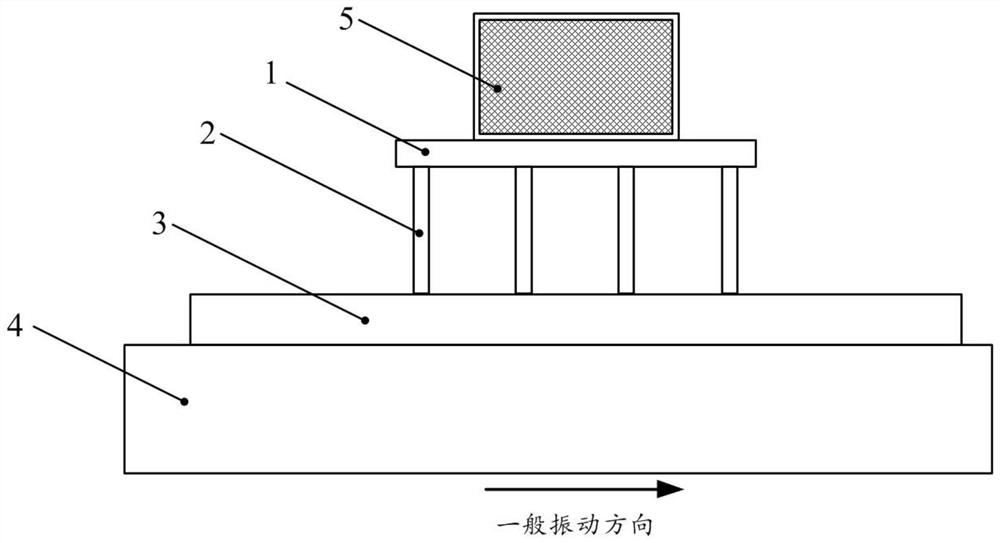

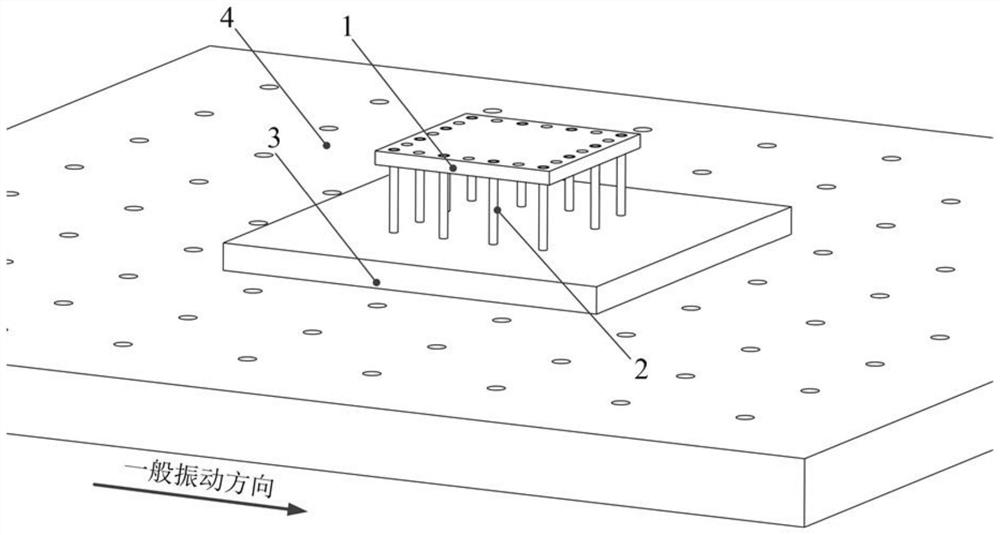

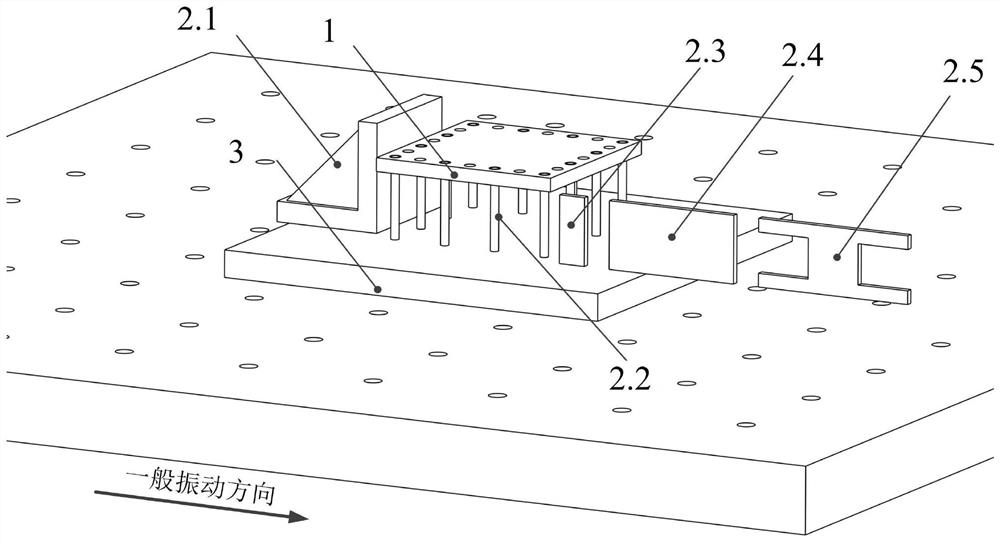

[0020] In one of the embodiments, the present invention provides a multi-dimensional vibration simulation device based on structural coupling, the device includes an upper platform 1, a simulation connector 2 and a lower platform 3, wherein the simulation connector 2 is used to connect the upper platform 1 and the lower platform The platforms 3 are rigidly connected together. Preferably, the simulated connector 2 adopts any one or any combination of the following structural forms: beam connection form (2.1), fixed support locking form (2.2), narrow plate form (2.3), wide plate form ( 2.4), heterosexual plate form (2.5), image 3 All structural forms that the analog connector 2 can adopt are shown in . For example, the simulated connector 2 adopts the combination of the beam connection form (2.1) and the fixed sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com