Grain drying method and system

A grain drying and grain drying technology, which is applied in the direction of drying solid materials, drying gas arrangement, control/regulation system, etc., can solve the problems of over-drying and long drying time, and achieve the effects of ensuring quality, efficient drying, and preventing over-drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

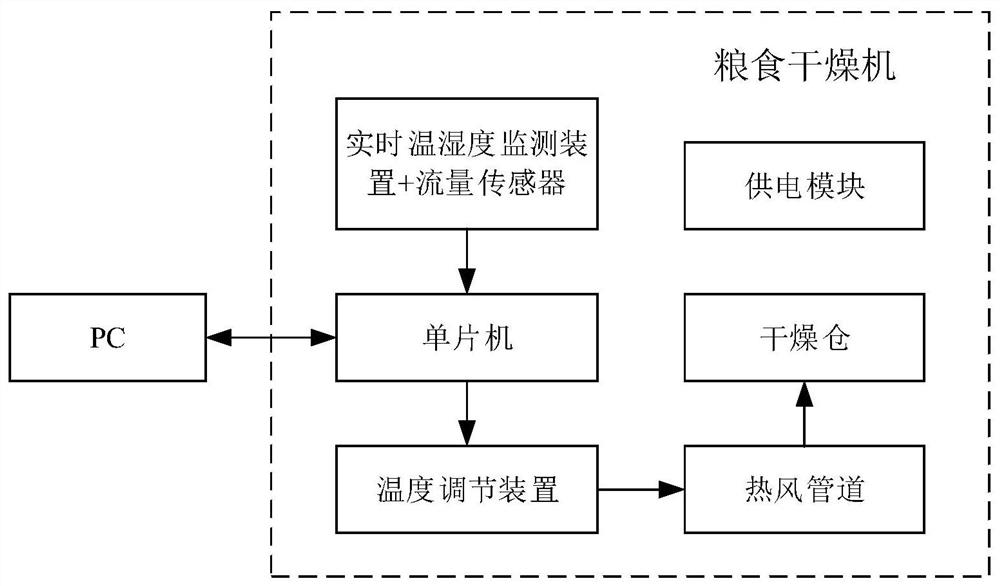

Method used

Image

Examples

Embodiment Construction

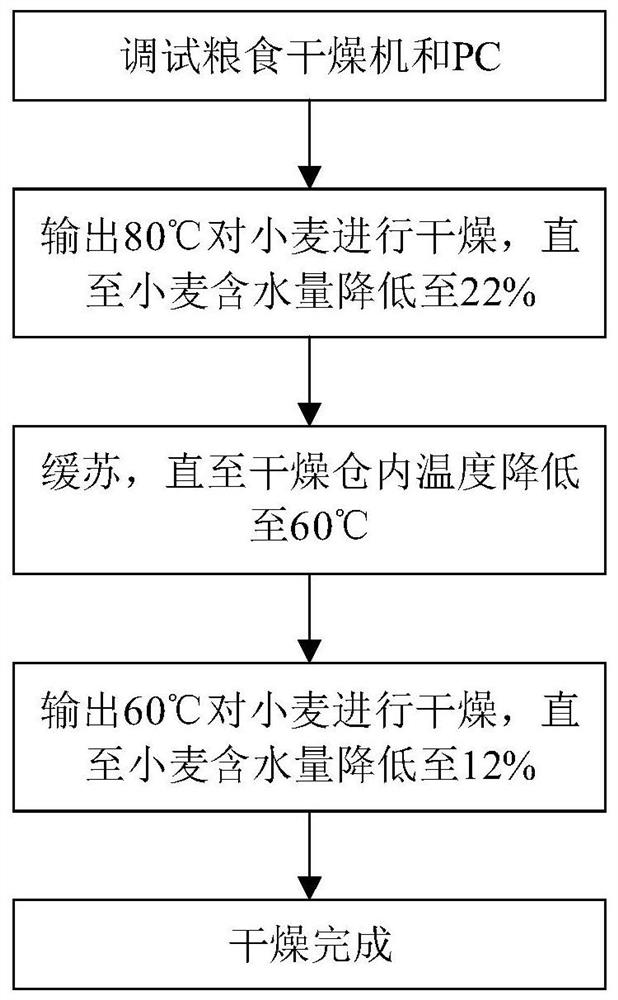

[0028] During the drying process of grain, its moisture activation energy is divided into its own free water E1, the activation energy Ew of physically bound water, and the activation energy Ea of chemically bound water. In the early stage of drying, it is the process of drying physically bound water and free water, and the drying process can be accelerated by using high temperature; in the later stage of drying, there is a process of converting chemically bound water into free water, and it is necessary to reduce the drying temperature to realize heat input and drying kinetics process matches.

[0029] Using this phenomenon, the whole process of drying grain is divided into three stages. In each stage, the grain dryer uses different input power of hot air. In the first stage, the output temperature of the grain dryer is controlled to be higher, and in the second stage, the temperature of the grain is controlled. The dryer stops the drying operation, and controls the grain dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com