Fabricated stair step and construction method thereof

A prefabricated and stair technology, used in stairs, treads, buildings, etc., can solve problems such as large construction waste, environmental pollution, and long construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

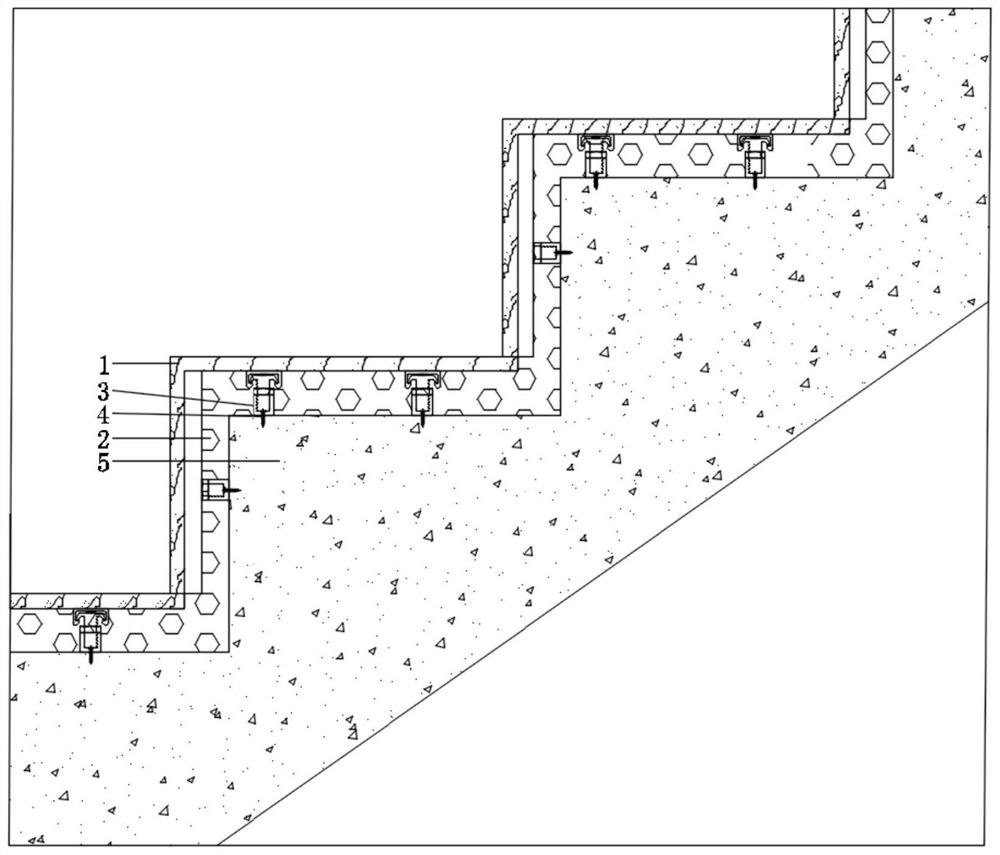

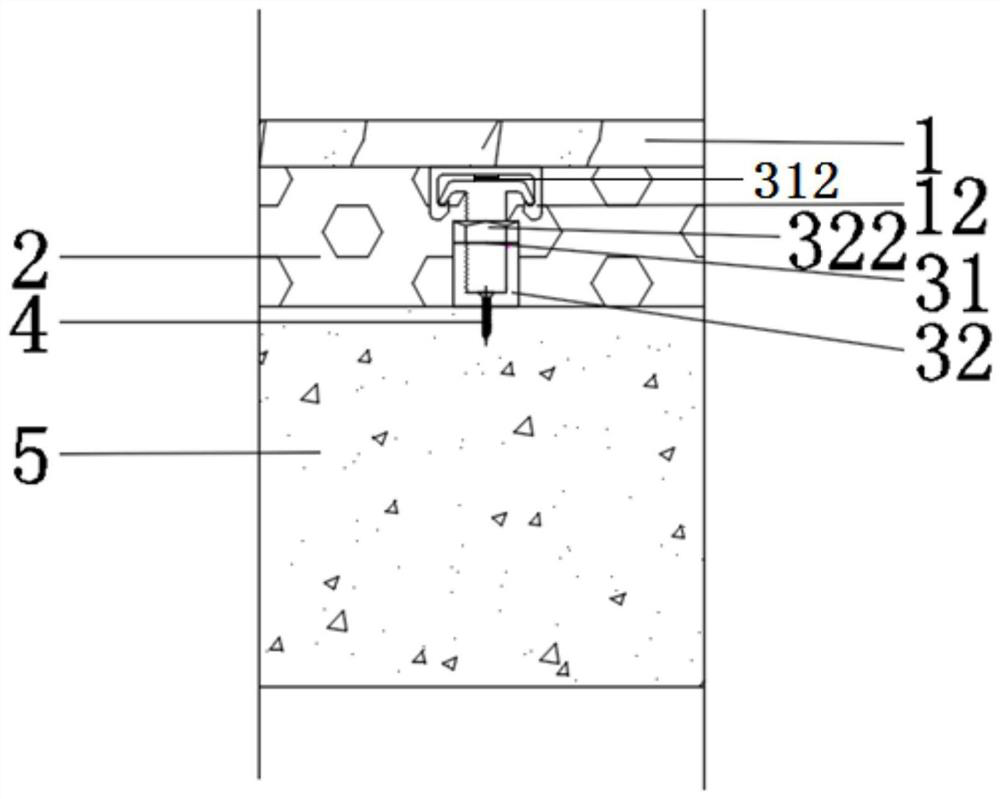

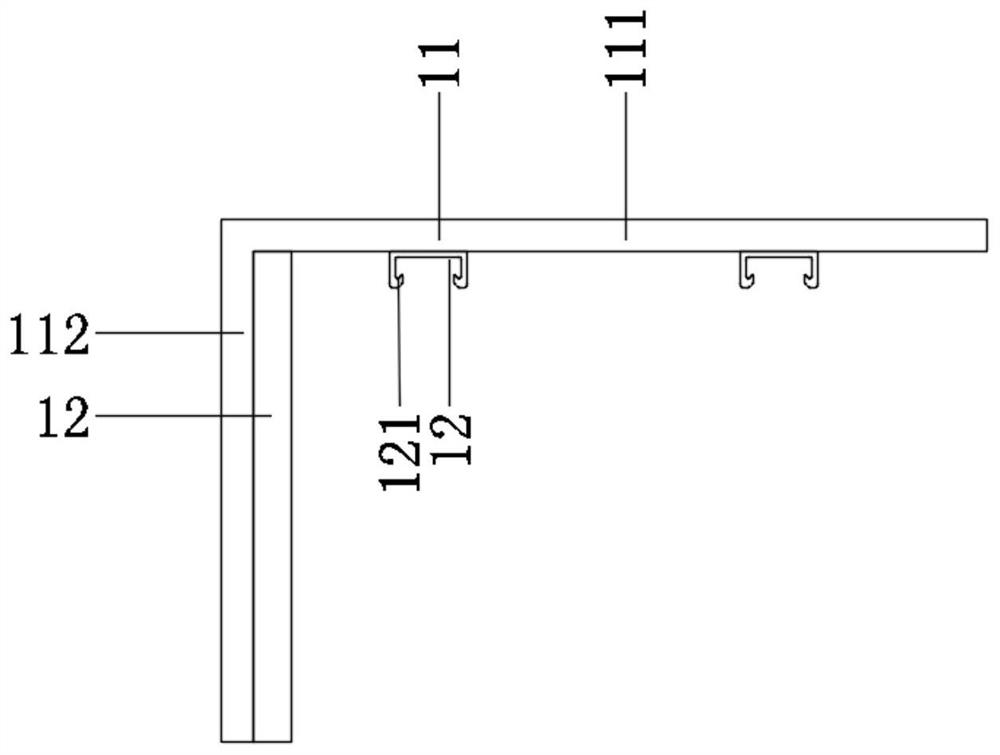

[0036] A prefabricated stair tread, such as Figure 1-Figure 3 As shown, it includes an L-shaped step unit part 1, a leveling device 3, and a first fixing member 4. The L-shaped step unit part 1 includes an L-shaped step surface layer 11 and a U-shaped groove reinforcement rib 12. The L-shaped step surface layer 11 includes The tread surface 111 and the kick surface 112, the U-shaped groove reinforcement 12 includes the tread U-shaped groove reinforcement 12, the kick surface U-shaped groove reinforcement 12, the leveling device 3 includes a T-shaped adjustment part 31 and a fixing device 32, and the U-shaped groove reinforcement The ribs 12 are fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com