Subway tunnel ballast bed surface and drainage ditch cleaning operation vehicle and drainage ditch flushing method

A technology for working vehicles and drainage ditch, which is applied in the direction of track cleaning, cleaning method, waterway system, etc., can solve the problem of not being able to effectively clean the drainage ditch of the subway tunnel floor slab online.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

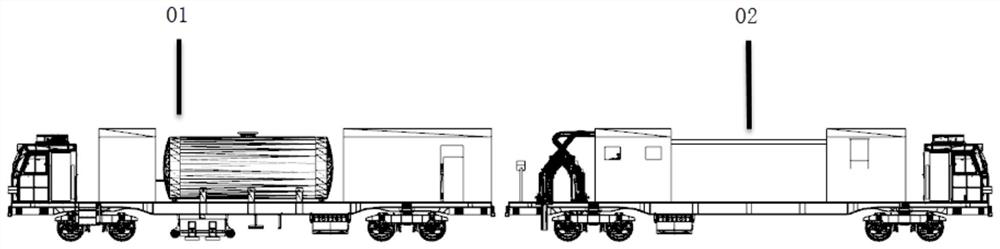

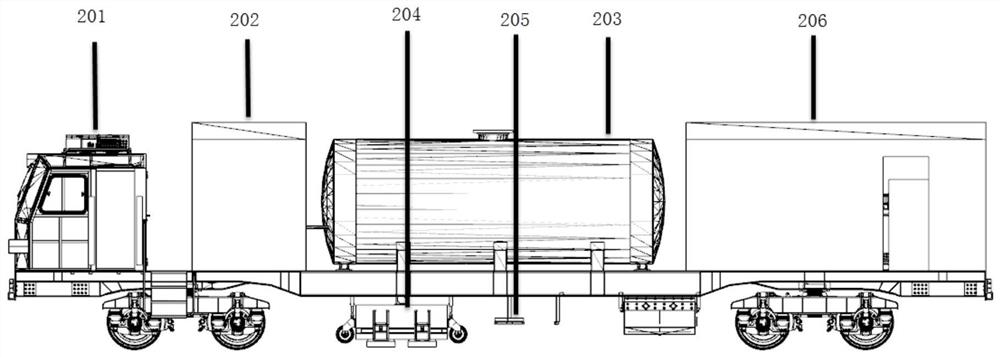

Embodiment 11

[0078] Example 1.1: A cleaning operation vehicle for the bed surface and drains of subway tunnels. It is the first to apply the "disc brush combined with water stripping" cleaning and dust removal method to the cleaning operation of subway tunnels, combining the use of disk brushes combined with high-pressure water for stripping, and low-pressure water for washing and stripping Pollutants leave the ballast bed, twister suction equipment to deal with drainage ditch sedimentation and other cleaning operations, and clean the track bed surface and drainage ditch of the subway tunnel.

[0079] The disc brush combined water stripping principle adopted by the subway tunnel bed surface and drainage ditch cleaning operation vehicle in this embodiment is: for the dust, metal iron filings and dust, oil stains, and tunnel surfaces attached to the subway tunnel track bed rails and rail rows. Exudation, etc., use a vertically rotating disc brush combined with water spray and use a certain am...

Embodiment 12

[0104]Embodiment 1.2: a kind of subway tunnel bed surface and drainage ditch cleaning operation vehicle, with embodiment 1.1, difference is: the subway tunnel road surface and drainage ditch cleaning operation vehicle self that present embodiment provides does not have power, and vehicle front and back is arranged There is a connecting device, which can be connected to a rail car or other power vehicles, and can be easily and quickly pulled by other power vehicles to the place where the work needs to be done. The design without carrying power can greatly reduce the cost of the vehicle.

[0105] The technical scheme of the subway tunnel bed surface and drainage ditch cleaning operation vehicle provided by the present invention includes any combination of the above-mentioned parts, especially the combination of two operation vehicles or separate operations, and the simple changes or combinations of the above-mentioned components are still the basic protection scope of the inventi...

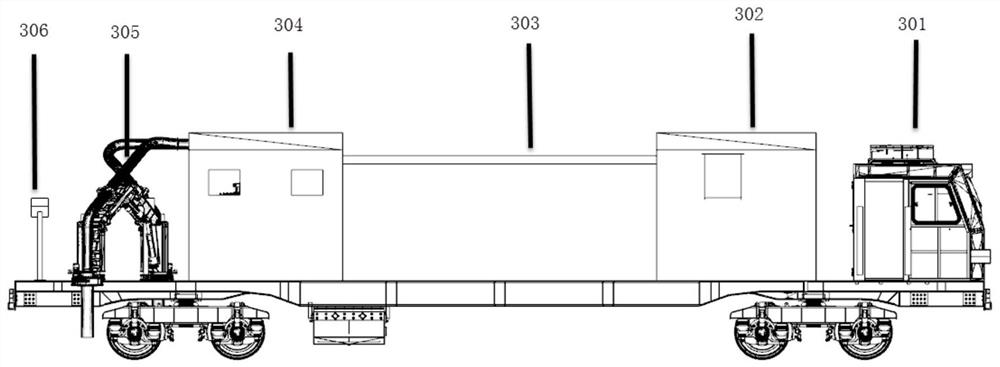

Embodiment 21

[0106] Embodiment 2.1: a kind of subway tunnel bed surface and drainage ditch flushing method: it comprises:

[0107] Step 1: Pump out high-pressure water through the water pump in the scrubbing device. At the same time as the high-pressure nozzle sprays water, the disc brush starts and rotates along the vertical axis, so that the dirt is brushed up under the combined action of high-pressure water and the disc brush;

[0108] Step 2: The heated water is output through the action of the water pump, and the high-pressure water sprayed from the pipeline of the flushing device performs secondary stripping, cleaning and flushing of the residual pollutants on the ballast bed, and flushes the pollutants stripped by the scrubbing device, Flush the above pollutants into the drainage ditch at the bottom of the railway tunnel;

[0109] Step 3: The stirring and sucking robot arm 305 includes a robot arm with multiple degrees of freedom, and a stirring and sucking device arranged at the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com