A steel-uhpc composite structure shear connector and its production and installation method

A combined structure and connector technology, applied to building components, structural elements, welding equipment, etc., can solve the problems of easy cracking of stud nail caps, low material utilization rate, insufficient shear strength, etc., and achieve relative slippage of the interface The effect of small quantity, shortened construction period and high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention is further described below with reference to specific preferred embodiments, but the protection scope of the present invention is not limited thereby.

[0047] For the convenience of description, the relative positional relationship of each component, such as: upper, lower, left, right, etc., are described according to the layout direction of the drawings in the specification, and do not limit the structure of this patent.

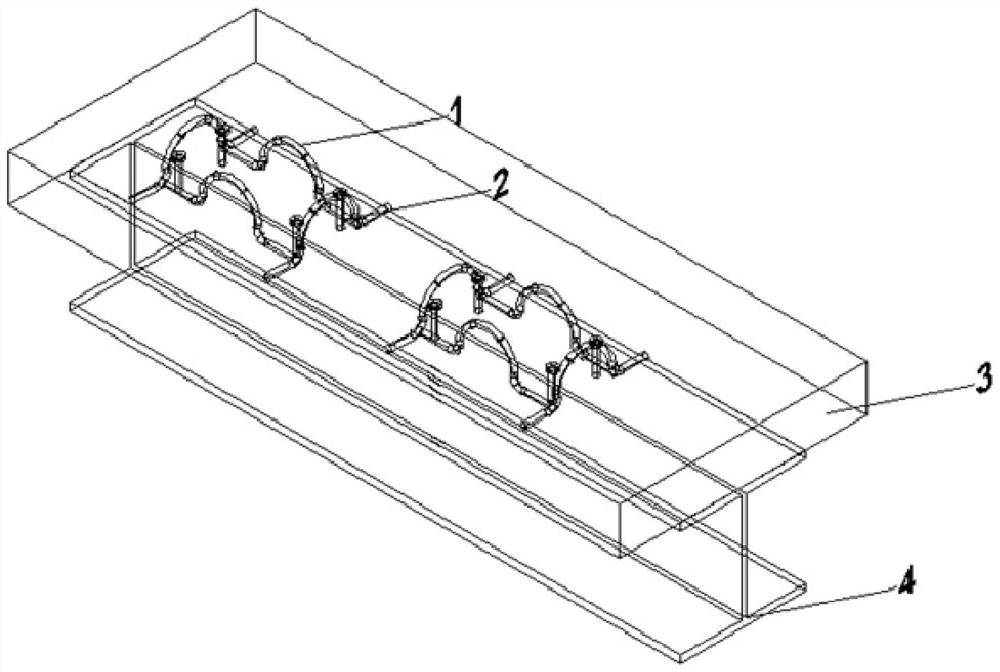

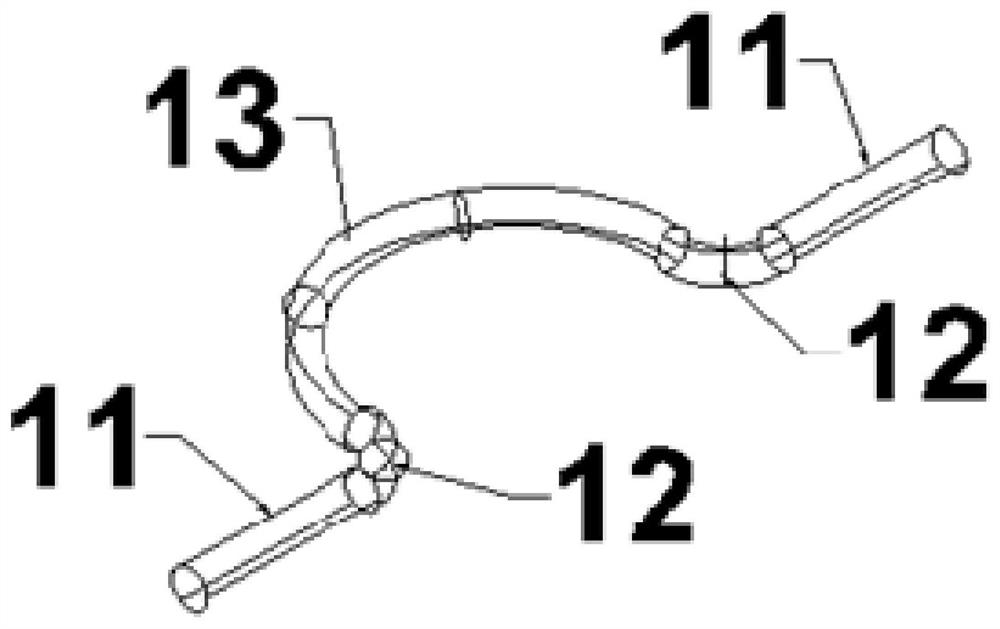

[0048] like figure 1 - image 3 As shown, an embodiment of the steel-UHPC composite structural shear connector of the present invention includes four shaped steel bars 1 formed by bending high-ductility hot-rolled ribbed steel bars, and the two ends of the shaped steel bars 1 are straight sections 11. The middle part is an arc section 13, the straight section 11 and the arc section 13 are smoothly connected by a transition section 12, and the four shaped steel bars 1 are spliced orthogonally to each other to form a mouth-sha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com