Inoculant carrier, preparation method and application thereof and preparation method for lactobacillus solid inoculant

A technology of solid bacterial agent and lactic acid bacteria, applied in the field of microorganisms, can solve the problems of loss of lactic acid, short storage period, waste of supernatant, etc., and achieve the effect of efficient production and reduction of waste water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

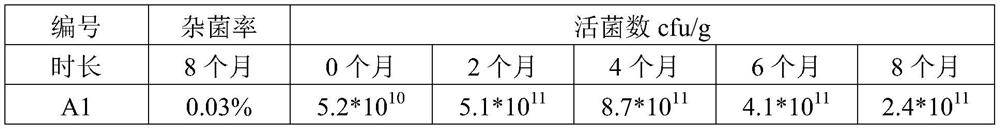

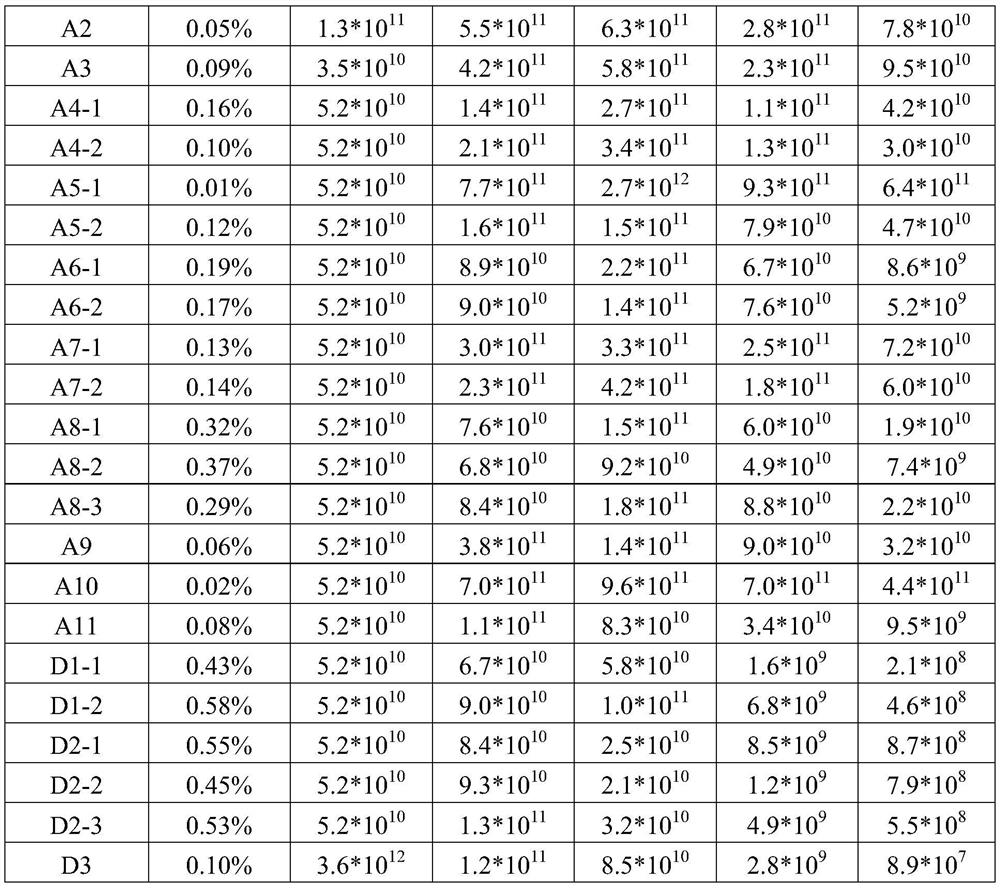

Examples

preparation example Construction

[0025] Another aspect of the present invention provides a method for preparing the bacterial agent carrier as described above, the method comprising: mixing calcium carbonate, crude fiber raw material powder, starch and montmorillonite to obtain the bacterial agent carrier.

[0026] In the present invention, the types and contents of calcium carbonate, crude fiber raw material powder, starch and montmorillonite involved in the preparation method of the above-mentioned bacterial agent carrier are all described in detail in the first aspect of the present invention, and will not be repeated here. repeat.

[0027] In the present invention, as long as the above components are directly mixed to prepare the bacterial agent carrier described in the present invention, and applying it to the preservation of the bacterial agent can effectively prolong the storage period of the prepared solid bacterial agent, In the case of preferably preparing the bacterial agent carrier according to th...

preparation example 1

[0066] This preparation example is used to illustrate the preparation method of lactic acid bacteria fermentation broth

[0067] 1) Strain activation: the Lactobacillus plantarum stored in an ultra-low temperature refrigerator was naturally thawed 0.5 h in advance, and inoculated into MRS broth medium with an inoculum volume of 0.2% by volume.

[0068] Culture conditions: static culture at 35°C. When the OD value grows to 6-7 and the pH is 4.0, the primary seed shake flask is finished.

[0069] 2) Secondary shake flask fermentation: the culture medium is MRS broth medium, the shake flask inoculum size: 0.2% by volume;

[0070] Culture conditions: static culture, temperature 35°C.

[0071] The OD value grows to 12-15, the pH is around 5.0, and the secondary seed shake flask is over.

[0072] 3) Expanded tank fermentation

[0073] The medium is MRS broth medium, and the inoculation amount is 0.2% by volume; the culture condition is static culture, and the temperature is 37°C...

Embodiment 1

[0076] This embodiment is used to illustrate the preparation method of the lactic acid bacteria solid microbial agent of the present invention

[0077] 1) After mixing 8g of calcium carbonate and 67g of rice husk powder evenly, measure and adjust the pH to 8.5 to obtain the first mixture;

[0078] 2) after the first mixture is mixed with 10g feed grade montmorillonite powder, the second mixture is obtained;

[0079] 3) The second mixture was uniformly mixed with 15 g of cornstarch, and the pH was measured and adjusted to 7 to obtain the bacterial agent carrier.

[0080] 4) Add 10 g of skim milk powder directly to 50 g of lactic acid bacteria fermentation broth and mix for 60 minutes to obtain a mixed bacterial agent.

[0081] 5) The bacterial agent carrier was added to the mixed bacterial agent and mixed, put into an oven for drying at a drying temperature of 35° C. and a drying time of 1 hour to obtain a solid lactic acid bacteria bacterial agent A1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com