Facultative-aerobic microorganism coexistence fermentation tank

An aerobic microorganism and fermenter technology, which is applied in the direction of bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, enzymology/microbiology device, etc., can solve the problems of increasing the degree of oxygen dissolution, complex structure, Problems such as low oxygen demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

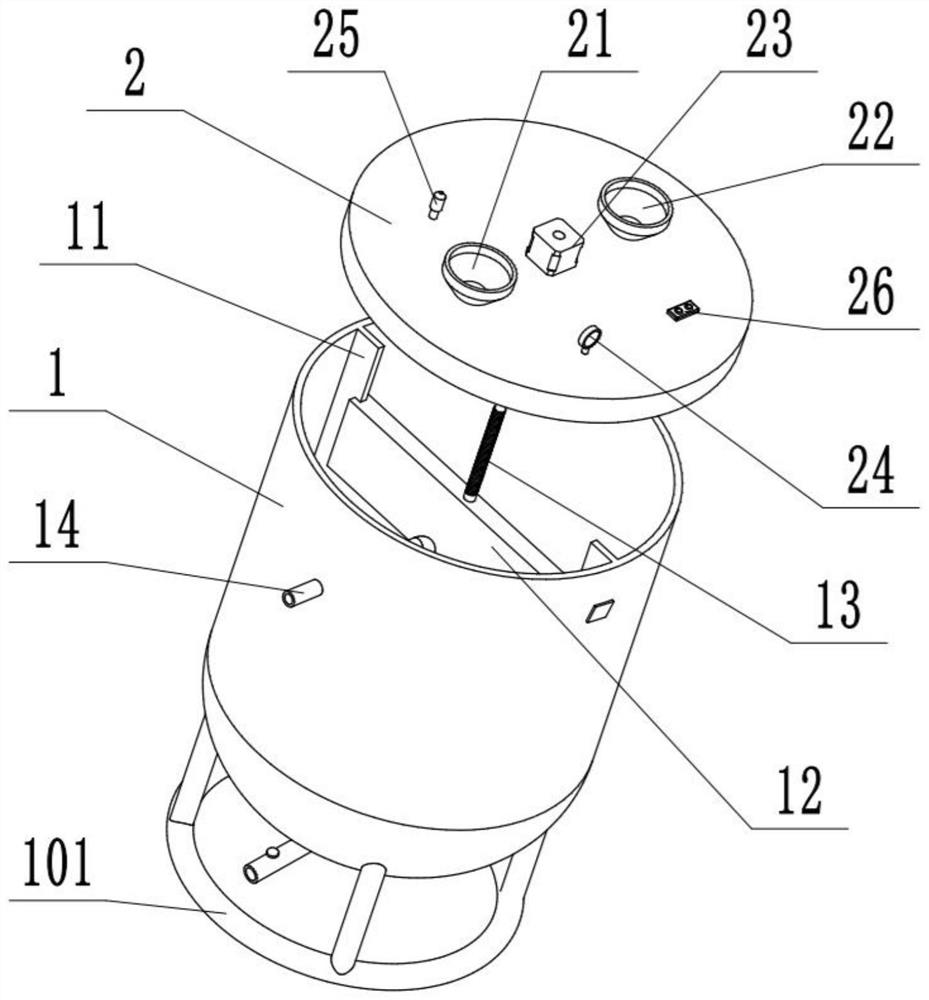

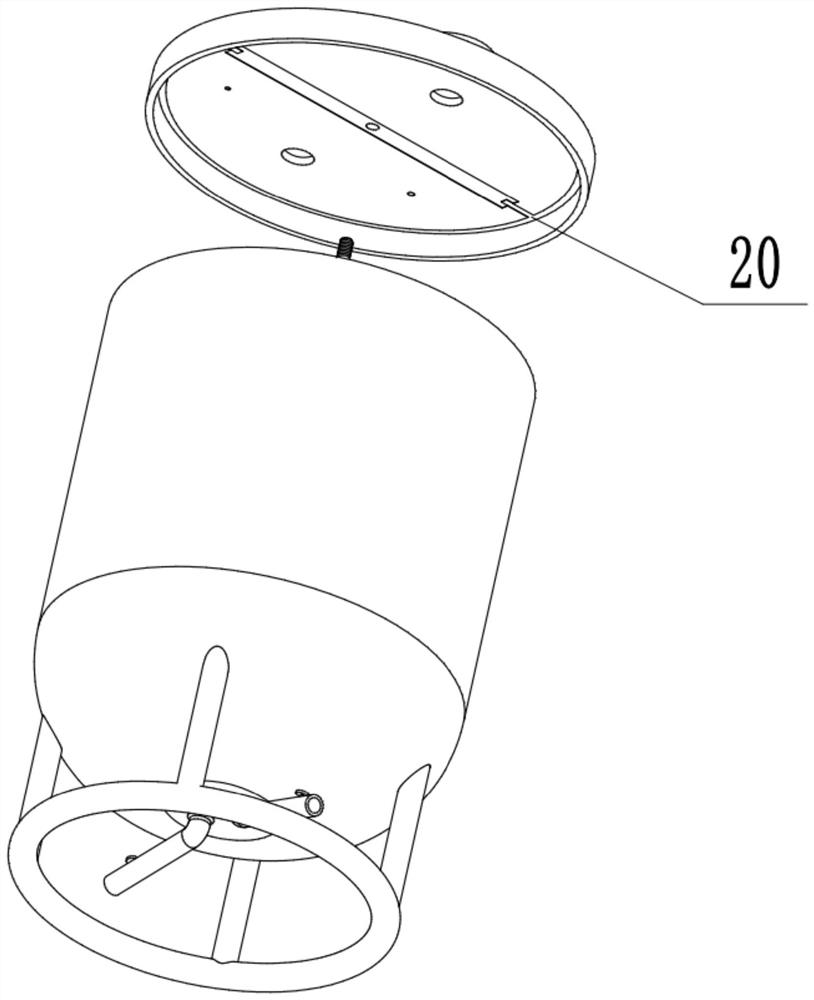

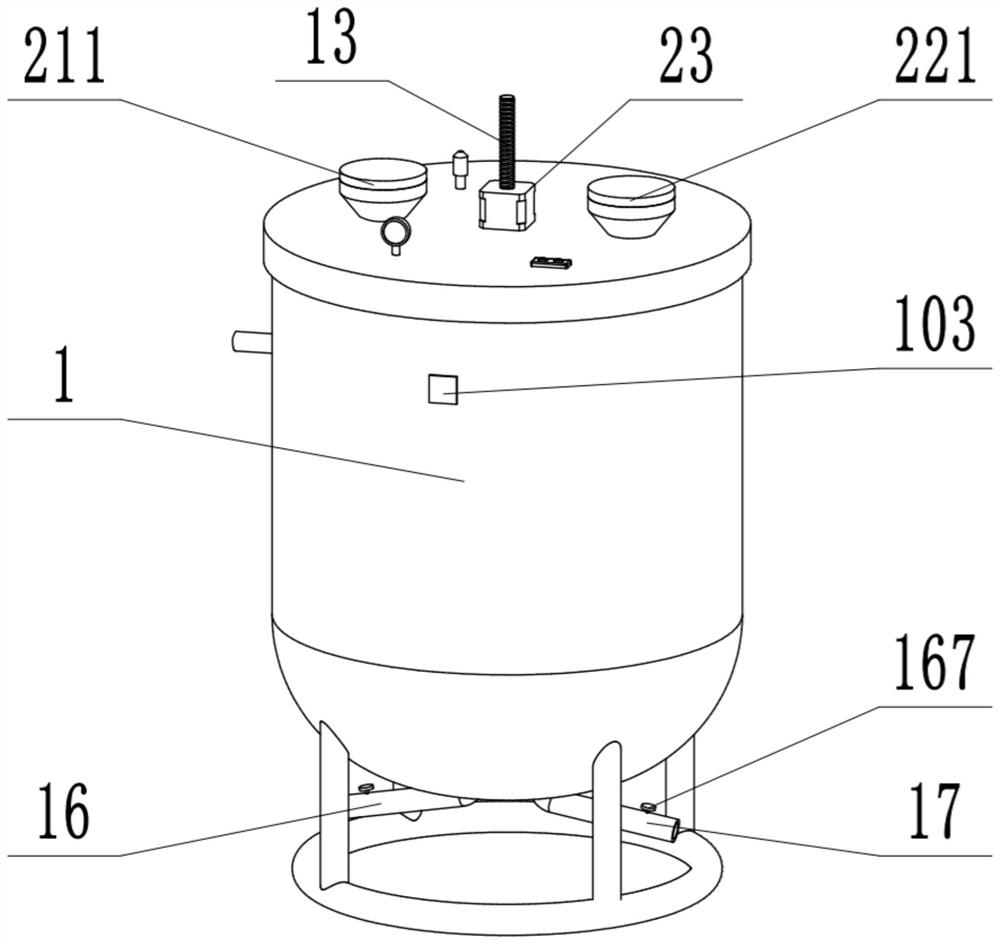

[0027] combined with Figure 1-7 , a facultative-aerobic microbial coexistence fermenter, comprising a tank body 1, the middle part of the tank body 1 is provided with a partition 11, the middle and lower part of the partition 11 is provided with a temperature sensor 10, and the upper part of the partition 11 slides Connect the sealing plate 12, the top of the sealing plate 12 is fixedly connected to the lead screw 13 in the middle, one side of the tank body is fixedly connected to the air inlet pipe 14, and the bottom of the air inlet pipe 14 in the tank body 1 is fixedly connected to the herringbone type air outlet device 15. The bottom of the tank body 1 is fixedly connected with a discharge pipe 1 16 and a discharge pipe 2 17 respectively, and the top of the tank body 1 is connected to the tank cover 2 with bolts, and the tank cover 2 is respectively provided with a feed hopper 1 21 and a feed hopper 2 22. A through-type linear motor 23 is fixedly installed in the upper mi...

Embodiment 2

[0040] For Example 1, different facultative microorganisms have different oxygen requirements during the fermentation process, and the oxygen concentration on the chamber side of the facultative microorganism solution can be changed in the following manner:

[0041] First, make the sealing plate at the lowest position and the tanks on both sides of the partition are in a connected state: ① Close the sealing cover 1 and open the sealing cover 2. At this time, the air needs to be discharged through the side cavity of the facultative microorganisms, the air circulation is good, and the oxygen concentration is low. High; ②Sealing cover 1 and sealing cover 2 are both open, at this time, there is air circulation in the cavities on both sides of the partition in the tank, and the air flow rate on the side of the facultative microorganisms is low, and the oxygen concentration is low; ③Open the sealing cover 1, close the sealing Cover 2. At this time, the air flow in the side chamber of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com