Textile winding disc device

A coiling and workbench technology, which is applied in the textile field, can solve the problems of thread entanglement and yarn flying on the thread and affect the environment, and achieve the effects of reducing the time for installing and disassembling the coiling coil, increasing the scope of application, and maximizing benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

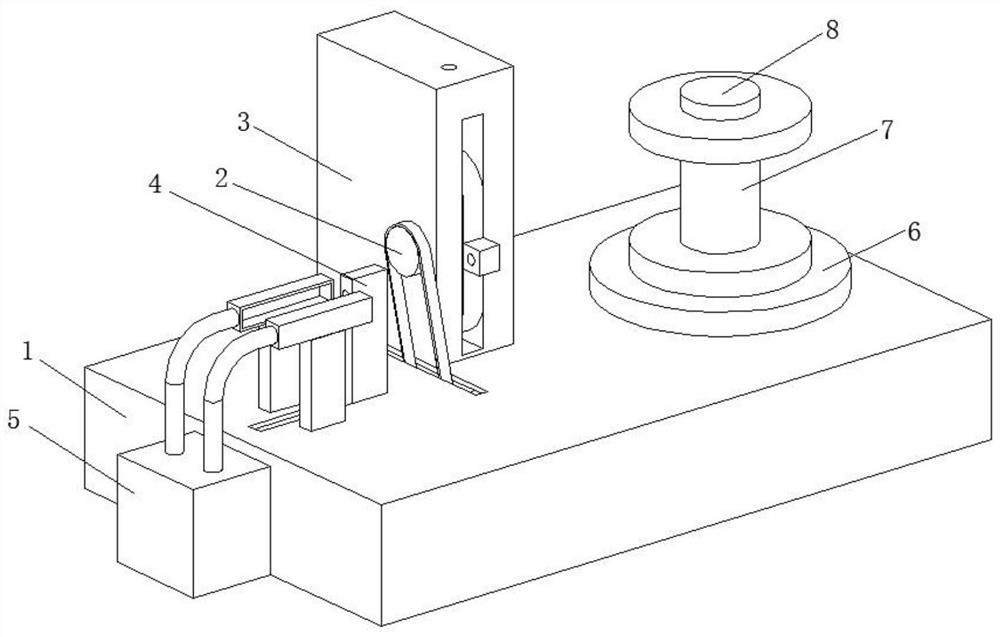

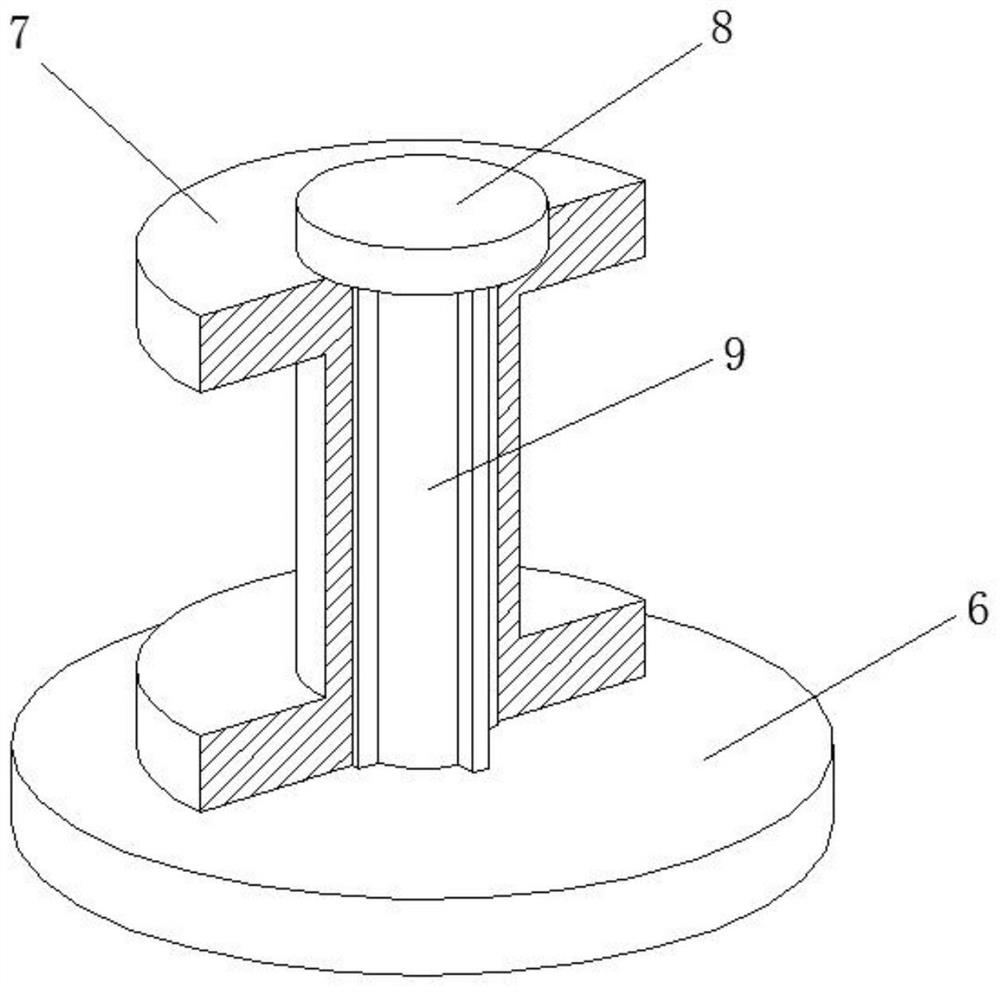

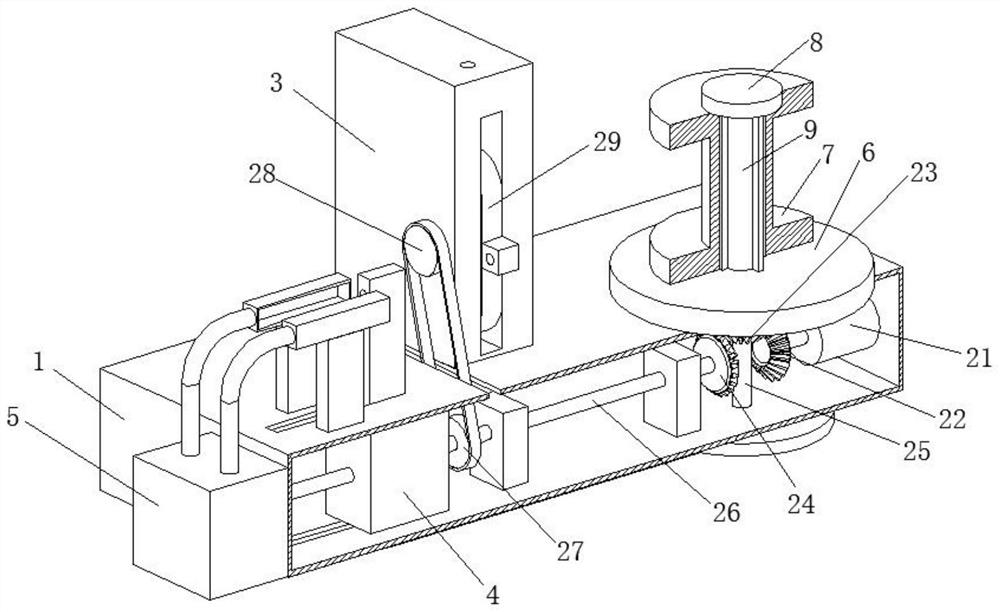

[0030]A textile winding device, such asFigure 1-Figure 5 As shown, the workbench 1 is included. The workbench 1 is provided with a transmission mechanism 2 inside, the top of the workbench 1 is welded with a fixed block 3, the inner wall of the workbench 1 is provided with a cleaning mechanism 4, and the front of the workbench 1 is provided with a collector Mechanism 5, the inner wall of the top of the workbench 1 is rotatably connected with a rotating shaft 9, the surface of the rotating shaft 9 is welded with a base 6, and the surface of the rotating shaft 9 is slidably connected with a winding reel 7, which is located above the base 6, and the top of the shaft 9 A top cover 8 is screwed.

[0031]The transmission mechanism 2 includes a motor 21. The output end of the motor 21 is clamped with a No. 1 bevel gear 22. The surface of the No. 1 bevel gear 22 is meshed with a No. 2 bevel gear 23. The surface of the No. 2 bevel gear 23 is meshed with a No. 3 bevel gear 24. A connecting shaft...

Embodiment 2

[0039]Such asFigure 6-Figure 7As shown, on the basis of Embodiment 1, in this embodiment, the fixing device 44 includes a sliding plate 441. The inner wall of the sliding plate 441 is slidably connected with a pull rod 442 and two limit posts 445, and the pull rod 442 is located in the two limit positions. Between the columns 445, the surface of the tie rod 442 is sleeved with a return spring 443, the bottom ends of the tie rod 442 and the limit column 445 are both welded with a pressure plate 444, the surface of the sliding plate 441 is slidingly connected to the inner wall of the top of the workbench 1, and the return spring 443 The two ends are in contact with the inner wall of the slide plate 441 and the upper surface of the pressure plate 444, and the pull rod 442 can drive the pressure plate 444 to move up, and then the larger diameter textile thread can be put into the slide plate 441. When you let go, the return spring 443 will The pressing plate 444 presses down the textile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com