Multi-cutter-bit conversion die cutting device for corrugated paper packaging boxes

A packaging box and multi-cutter technology, which is applied in packaging, transportation, packaging, papermaking, etc., can solve the problems of low work efficiency and inability to die-cut four packaging boxes, and achieve the effect of improving work efficiency and preventing movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

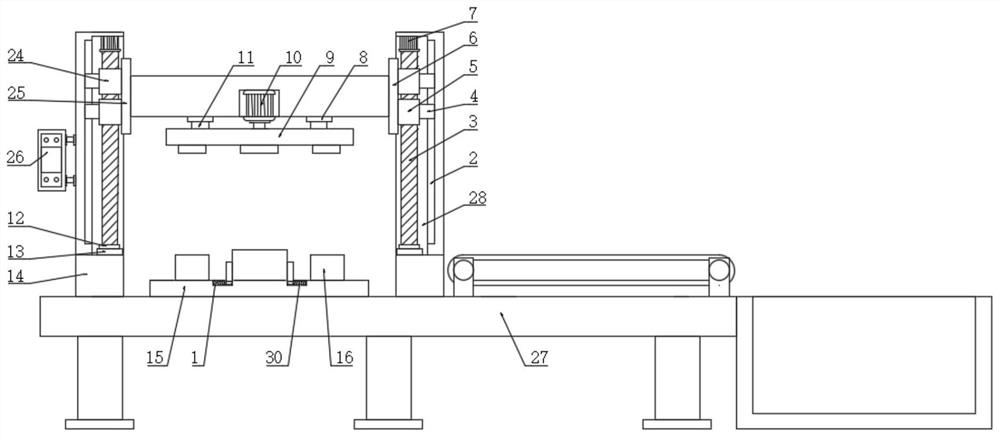

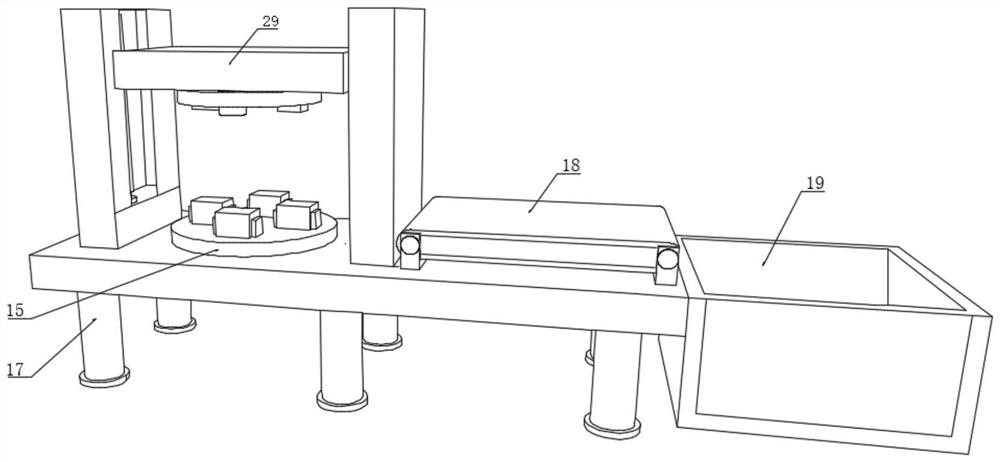

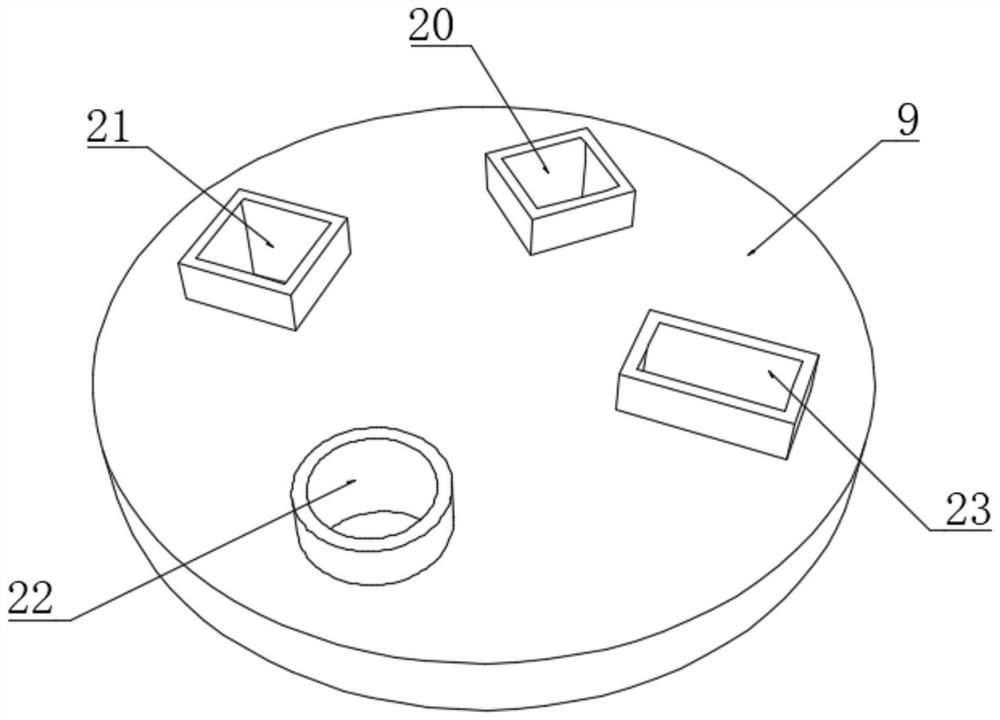

[0025] see Figure 1-5 , the present invention provides the following technical solutions: a corrugated paper packaging box multi-cutter head conversion die-cutting device, including a bottom plate 27, the top of the bottom plate 27 is fixedly connected with a side riser 14, the number of side risers 14 is two, and the two sides The vertical plate 14 is provided with a first chute 28 and a second chute 2, the second chute 2 is located on one side of the first chute 28, and the first chute 28 and the second chute 2 are connected, and the two The bottom of the inner wall of each first chute 28 is fixedly connected with a second bearing 13, and the second rotating shaft 12 is movably worn in the two second bearings 13, and one end of the two second rotating shafts 12 is fixedly connected with a threaded rod 3 , the tops of the two threaded rods 3 are fixedly connected with the output shafts of the second motor 7, the outer surfaces of the two second motors 7 are fixedly connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com