Preparation method of acrylic acid grafted modified graphene with high adsorption performance

An acrylic acid grafting, graphene technology, applied in chemical instruments and methods, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as poor graphene dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

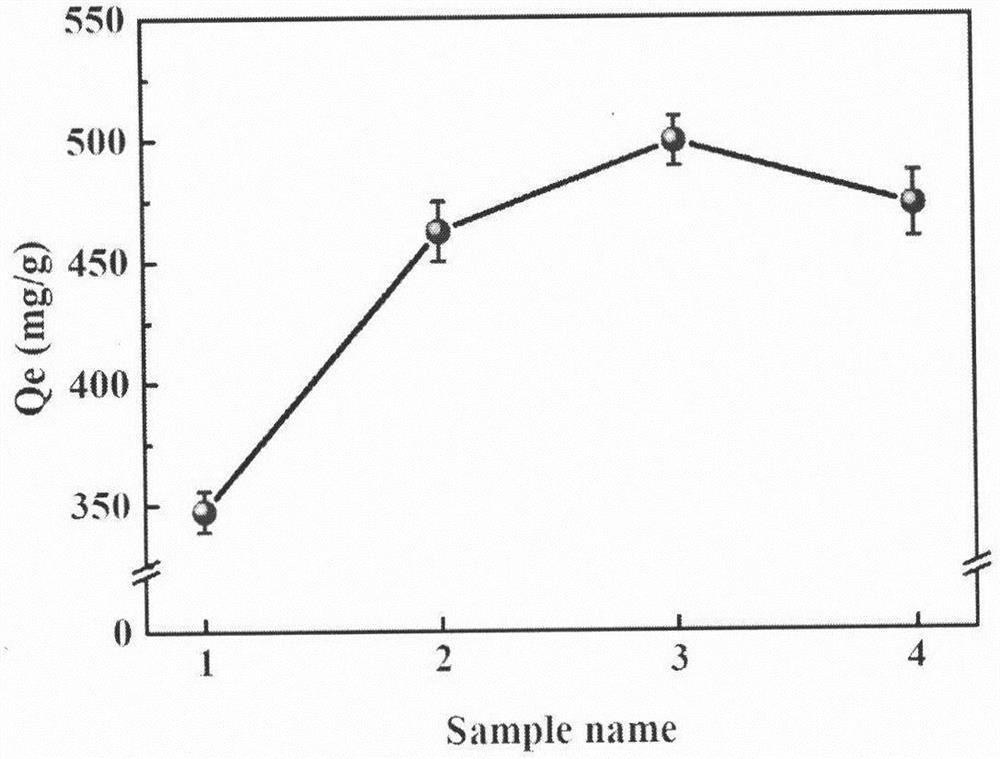

Embodiment 1

[0023] A method for preparing acrylic acid grafted modified graphene with high adsorption performance, comprising the steps of:

[0024] Add 0.5 g of native graphene oxide to 200 ml of mixed acid mixed with concentrated sulfuric acid and concentrated nitric acid at a ratio of 3:1, perform acid oxidation treatment by ultrasonication for 1 h, then wash with deionized water and centrifuge until the centrifuged supernatant is neutral. Finally, the graphene was dried at 65° C. for 12 hours to obtain mixed acid pretreated graphene oxide in Example 1.

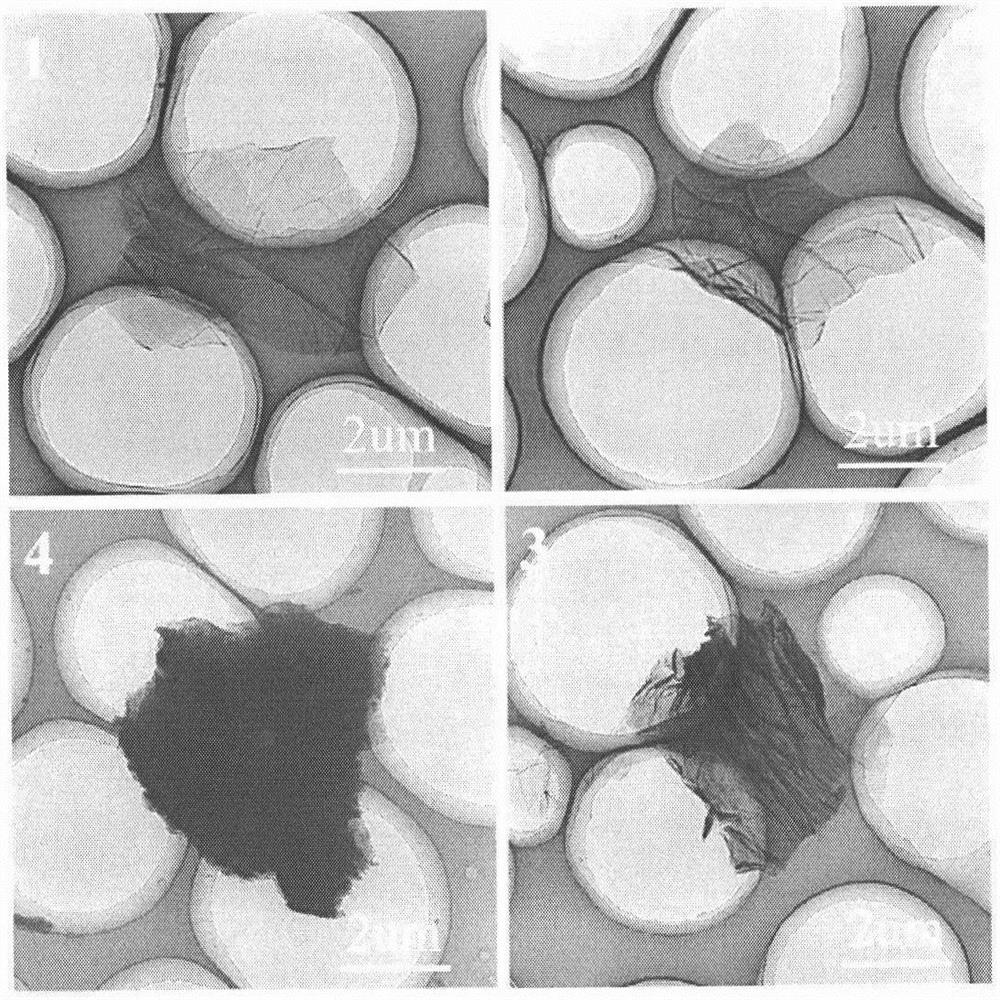

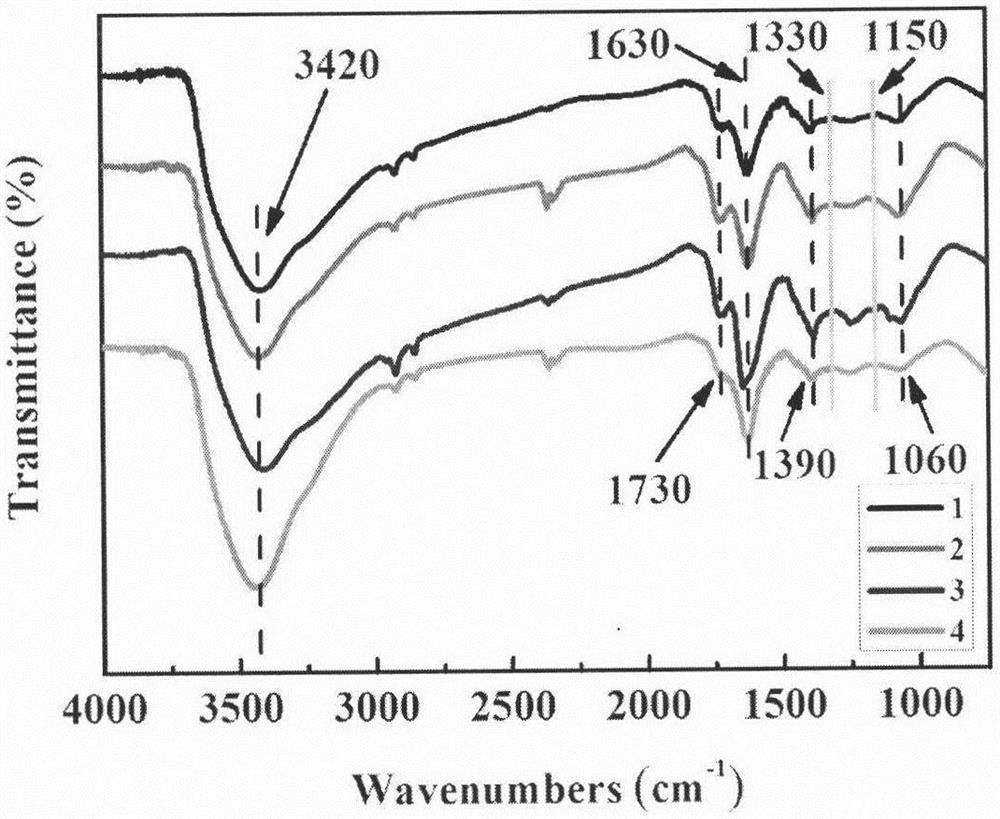

[0025] Utilize HITACHI TECNAI-20 transmission electron microscope and German Bruker company TENSOR37 Fourier transform infrared spectrometer to test the mixed acid pretreated graphene oxide prepared in the present embodiment 1, obtain figure 1 (1) and figure 2 (1).

Embodiment 2

[0027] A method for preparing acrylic acid grafted modified graphene with high adsorption performance, comprising the steps of:

[0028] 1) with the operation steps in embodiment 1;

[0029] 2) Add 0.1 g of the dried mixed-acid pretreated graphene oxide into 60 ml of deionized water, and ultrasonically disperse the graphene oxide evenly for 1 hour. Then add 1ml of acrylic acid monomer, add 0.0105g (1% of the mass of acrylic acid) potassium persulfate initiator, and stir in a water bath at 60°C for 6h. After the stirring was completed, it was washed with deionized water and centrifuged, and then the graphene oxide was dried at 65° C. for 12 hours to obtain the modified graphene oxide of Example 2.

[0030] Utilize HITACHI TECNAI-20 transmission electron microscope and German Bruker company TENSOR37 Fourier transform infrared spectrometer to test the modified graphene oxide that present embodiment 2 makes, obtain figure 1 (2) and figure 2 (2).

Embodiment 3

[0032] A method for preparing acrylic acid grafted modified graphene with high adsorption performance, comprising the steps of:

[0033] Change the addition amount of step 2) acrylic acid monomer into 2ml in embodiment 2, the addition amount of initiator is changed into 0.0210g, all the other conditions are the same as embodiment 2, obtain embodiment 3 modified graphene oxide.

[0034] Utilize HITACHI TECNAI-20 transmission electron microscope and German Bruker company TENSOR37 Fourier transform infrared spectrometer to test the modified graphene oxide prepared in the present embodiment 3, obtain figure 1 (3) and figure 2 (3).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com