Continuous flow magnetic induction electric field low-temperature sterilization device and method

A magnetic induction and electric field technology, applied in the field of continuous flow magnetic induction electric field low temperature sterilization device, can solve the problems of slow heating rate, electrode plate corrosion, long sterilization time, etc., achieve low temperature and rapid sterilization, sensitive electric field effect, and reduce the effect of sterilization temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

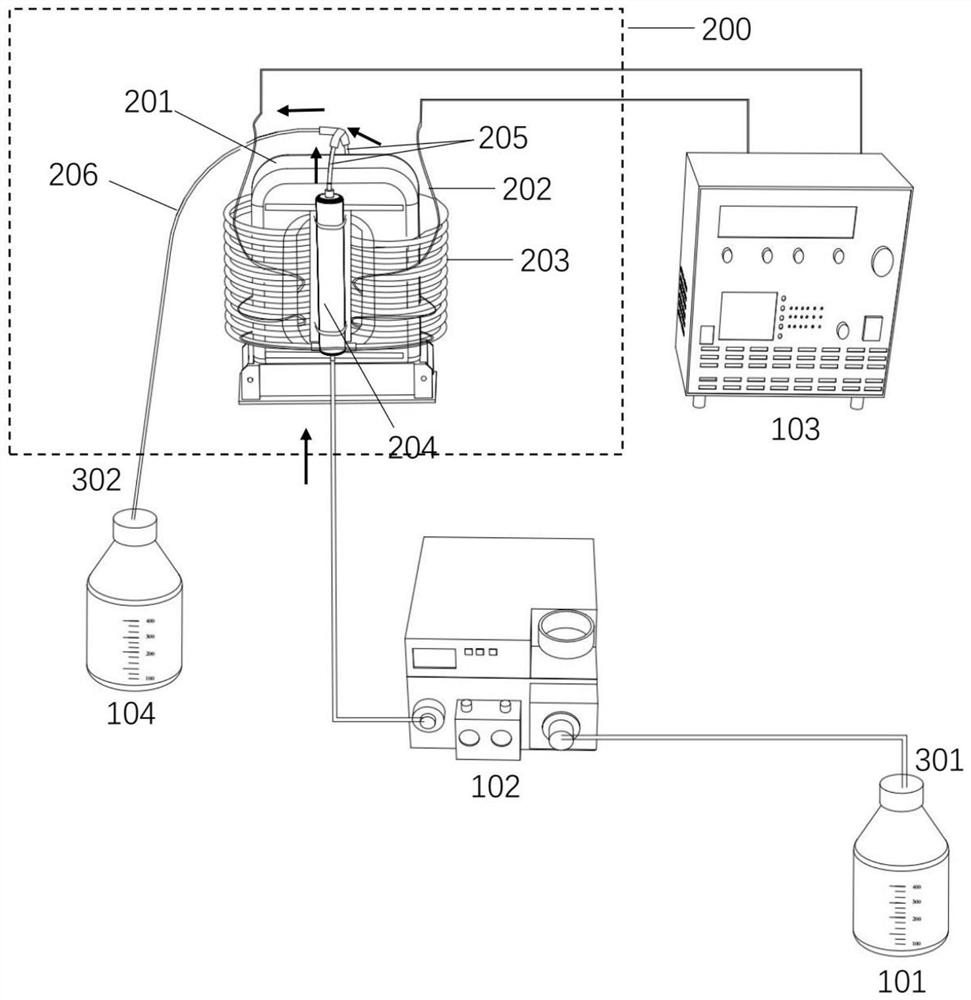

[0036]This embodiment provides a continuous flow magnetic induction electric field low-temperature sterilization device, seefigure 1 , The device includes: a sample bottle 101, a pump 102, a power source 103, a sample bottle 104 and a sterilization treatment equipment 200.

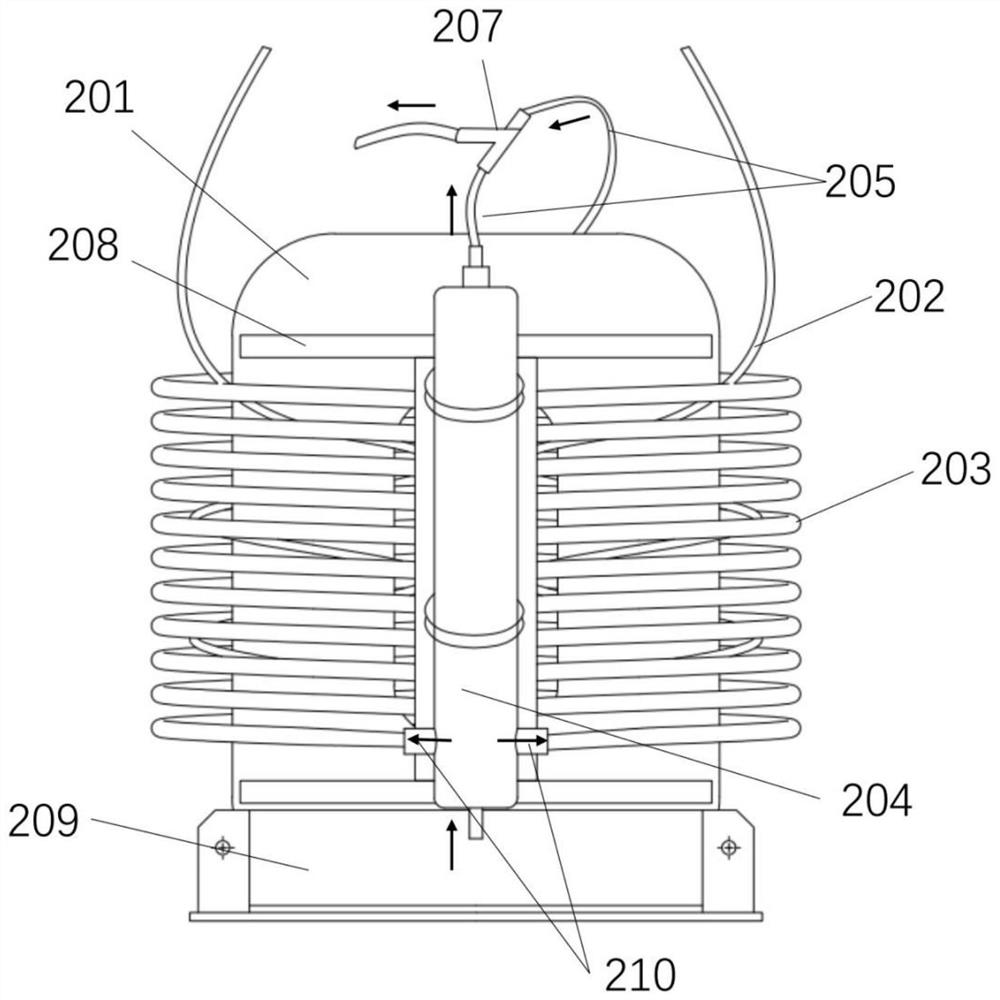

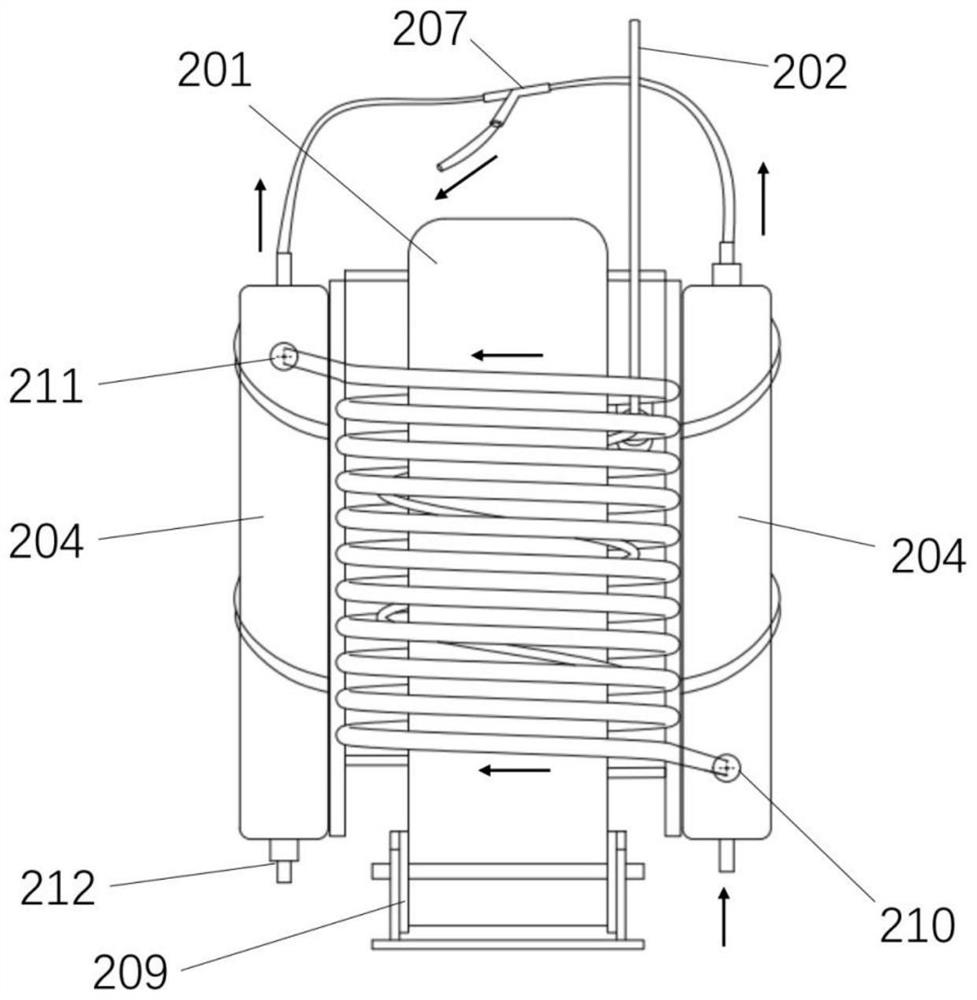

[0037]Such asFigure 2-Figure 4As shown, the sterilization treatment equipment 200 includes: a magnetic core 201, an excitation coil 202, a magnetic coupling tube 203, a storage tube 204, a processing chamber 205, a liquid outlet tube 206, a three-way connector 207, a fixing plate 208 and a base 209 .

[0038]Such asfigure 2 As shown, in the sterilization treatment equipment 200, the excitation coil 202 and the magnetic coupling tube 203 are both wound on both sides of the magnetic core 201. The excitation coil 202 is connected to the power source 103.

[0039]byimage 3 Side view shown andFigure 4 As can be seen from the top view shown, the sterilization treatment equipment 200 includes two storage tubes 204, which are re...

Embodiment 2

[0058]This embodiment provides a sterilization method using the continuous flow magnetic induction electric field low-temperature sterilization device given in the first embodiment. The material liquid is kiwi juice filtered through four layers of gauze as an example.

[0059]Specific, such asfigure 1 As shown, the continuous flow magnetic induction electric field low-temperature sterilization device used includes: a sample bottle 101, a pump 102, a power source 103, a sample bottle 104 and a sterilization treatment equipment 200. The sterilization treatment equipment 200 includes: a magnetic core 201, an excitation coil 202, a magnetic coupling tube 203, a storage tube 204, a processing chamber 205, a liquid outlet tube 206, a three-way connector 207, a fixing plate 208 and a base 209.

[0060]The magnetic core 201 is composed of an amorphous nanocrystalline soft magnetic material.

[0061]In this embodiment, the excitation coil 202 is wound on the magnetic core 201. The number of turns of ...

Embodiment 3

[0070]This embodiment provides a sterilization method using the continuous-flow magnetic induction electric field low-temperature sterilization device given in the first embodiment, and the material liquid is fresh cow milk as an example.

[0071]Specific, such asfigure 1 As shown, the continuous flow magnetic induction electric field low-temperature sterilization device used includes: a sample bottle 101, a pump 102, a power source 103, a sample bottle 104 and a sterilization treatment equipment 200. The sterilization treatment equipment 200 includes: a magnetic core 201, an excitation coil 202, a magnetic coupling tube 203, a storage tube 204, a processing chamber 205, a liquid outlet tube 206, a three-way connector 207, a fixing plate 208 and a base 209.

[0072]The magnetic core 201 is composed of an amorphous nanocrystalline soft magnetic material.

[0073]In this embodiment, the excitation coil 202 is wound on the magnetic core 201. The number of turns of the excitation coil 202 is 4 t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| magnetic flux | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com